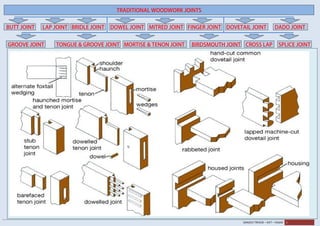

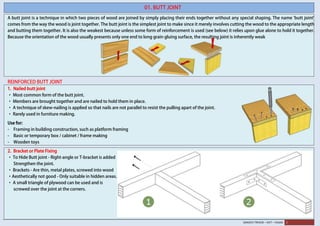

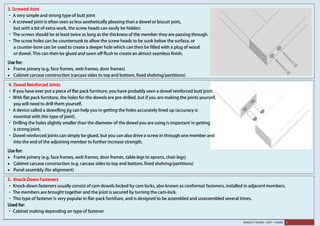

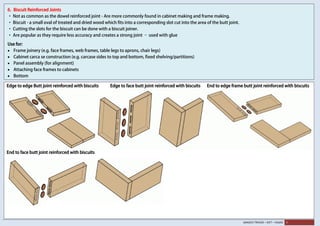

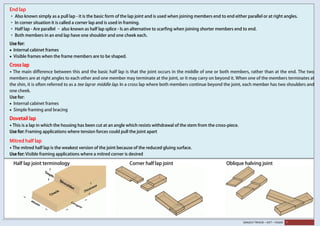

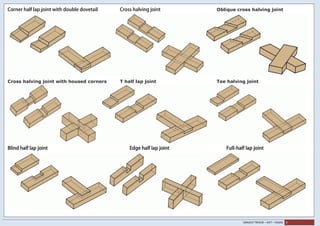

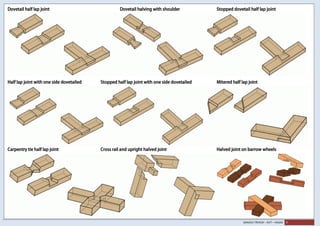

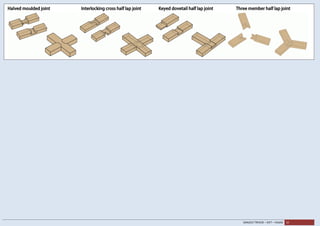

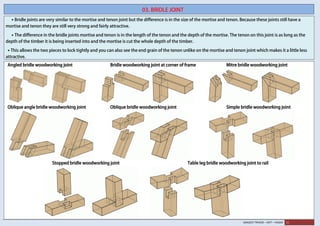

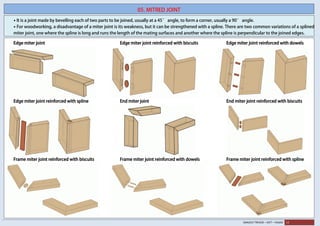

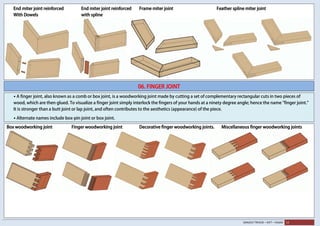

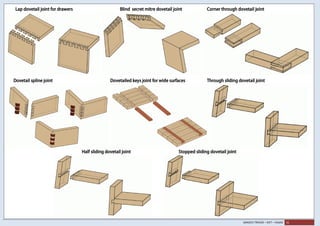

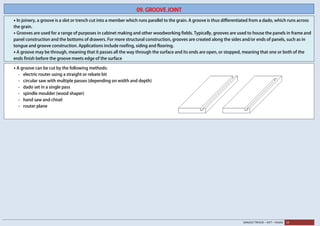

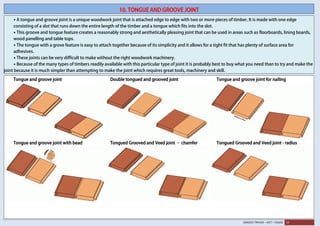

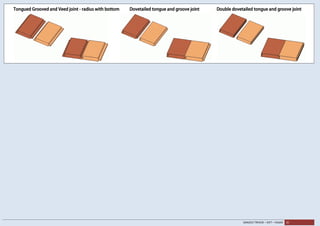

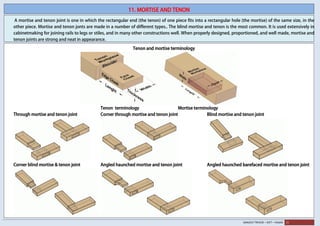

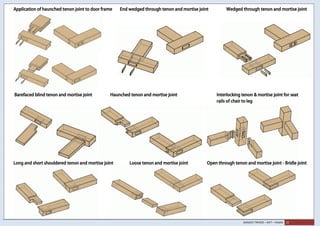

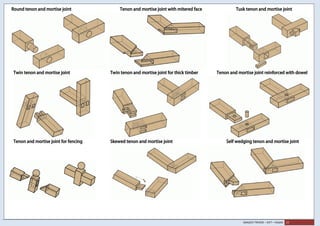

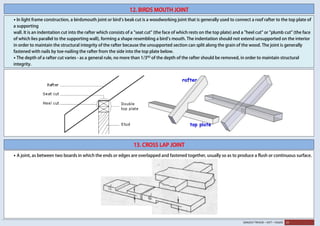

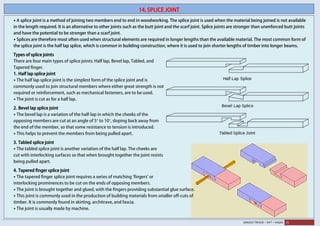

The document describes various types of traditional woodworking joints including butt joints, lap joints, bridle joints, dowel joints, mitred joints, finger joints, dovetail joints, dado joints, groove joints, tongue & groove joints, mortise & tenon joints, and birdsmouth joints. It provides details on butt joints and lap joints, describing different variations of each type of joint and their typical applications in woodworking. Butt joints are the simplest but weakest type of joint while lap joints join two pieces of wood by overlapping their edges or ends.