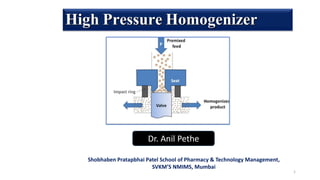

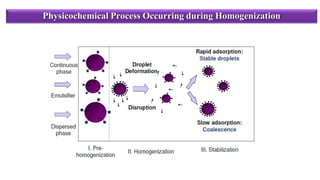

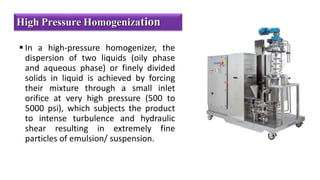

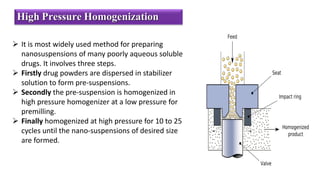

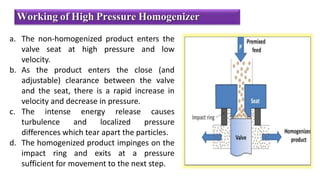

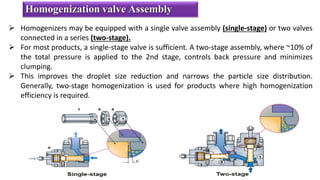

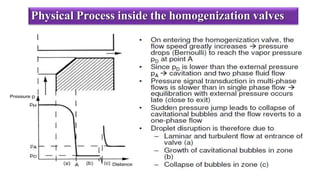

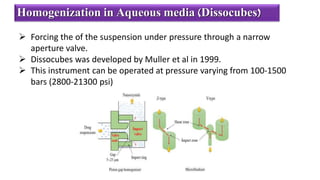

The document discusses high-pressure homogenizers, which are essential for producing consistent emulsions and suspensions in various industries such as food, pharmaceuticals, and personal care. It details the homogenization process, including mechanisms like cavitation and turbulent eddies, as well as the advantages and disadvantages of using high-pressure homogenizers for particle size reduction. Overall, high-pressure homogenization enhances product stability, consistency, and reduces contamination risks while maintaining stringent operational parameters.