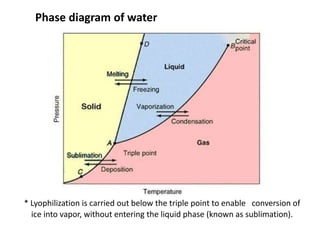

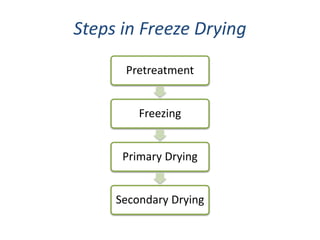

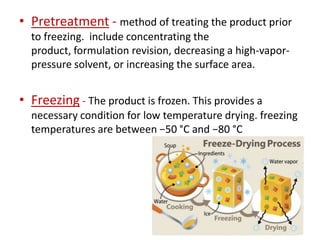

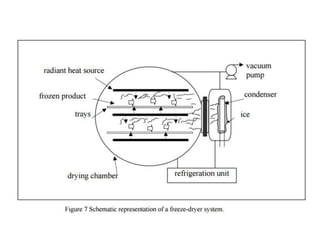

Freeze drying, also called lyophilization, is a process where material is frozen and then subjected to high vacuum pressure to sublime the frozen water in the form of vapor. It involves pretreating the product, freezing it, primary drying where ice sublimes under low pressure and heat, and secondary drying to remove remaining unfrozen water. Freeze drying retains most of the food's structure, flavor, and nutrients and produces a lightweight product with a long shelf life.