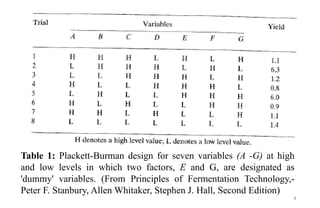

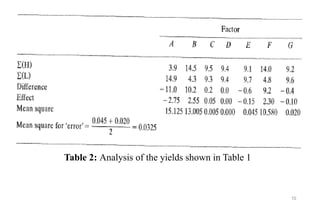

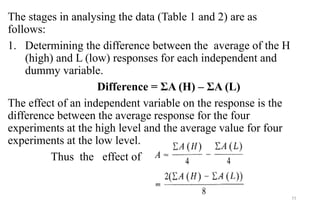

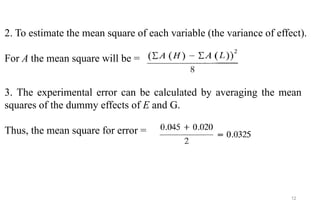

This document discusses the Plackett-Burman method for optimizing media in industrial processes. It begins by introducing media optimization and some traditional methods. It then describes the Plackett-Burman design, which allows for testing multiple variables simultaneously using a minimal number of experiments. The method involves designing experiments that test variables at high and low levels. The effects of each variable are then calculated and analyzed using statistical tests to identify the most important factors to optimize. Key advantages of the Plackett-Burman method are that it allows evaluation of many variables with fewer experiments than traditional methods.