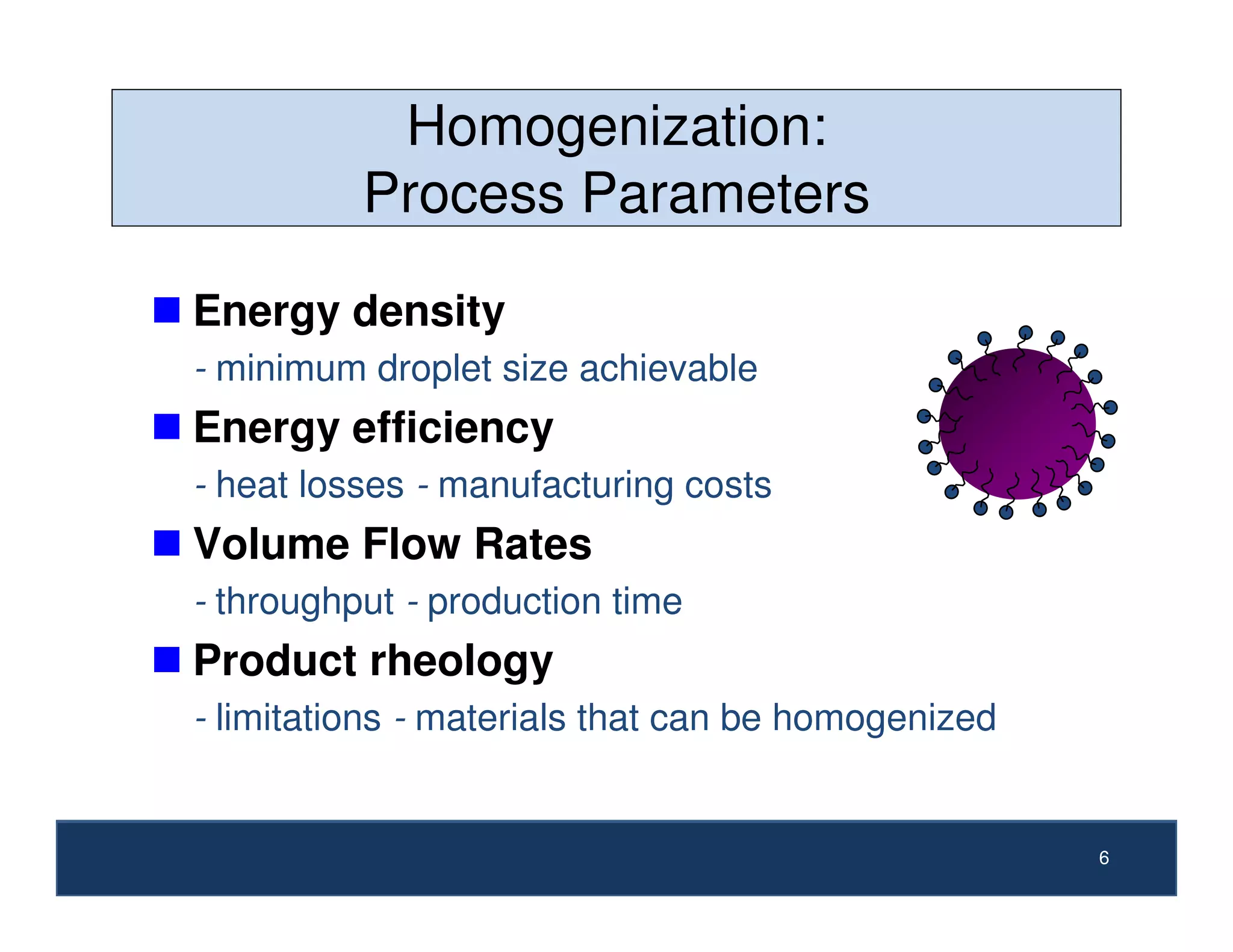

Homogenization is a unit operation that uses homogenizers to reduce the size of droplets in liquid-liquid dispersions. The key homogenization methods discussed are high pressure homogenization, colloid mills, high shear dispersers, ultrasonic homogenizers, and membrane homogenizers. The document outlines the operating principles of each type of homogenizer and the important process parameters that influence droplet size, such as energy density, emulsifier properties, and viscosity ratios of the dispersed and continuous phases. Selecting the appropriate homogenizer depends on the desired emulsion characteristics and production conditions.

![Factors Affecting Droplet Size:

Emulsifier Concentration

0.2

0.4

0.6

0.8

1

1.2

1.4

0 0.2 0.4 0.6 0.8

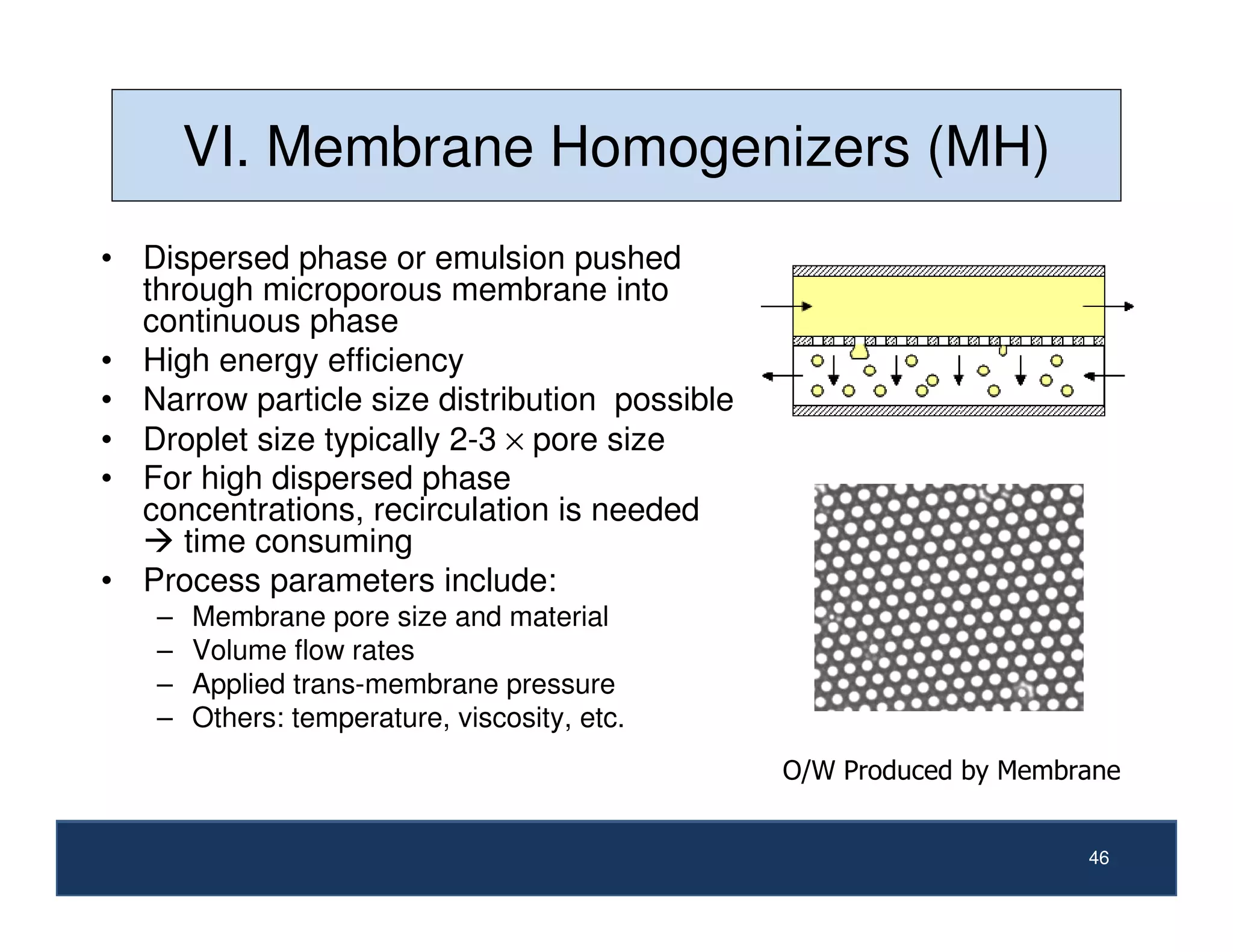

Once the emulsifier

concentration exceeds a

certain level the droplet size

depends on the energy input

of the homogenizer.

Corn O/W emulsion - Pandolfe (1995)

Fixed Homogenization

Conditions (1000 psi)

Emulsifier/Oil

Mean

Droplet

Diameter

[µm]](https://image.slidesharecdn.com/5emulsionformation-220826023525-673736e0/75/5-Emulsion_Formation-pdf-13-2048.jpg)

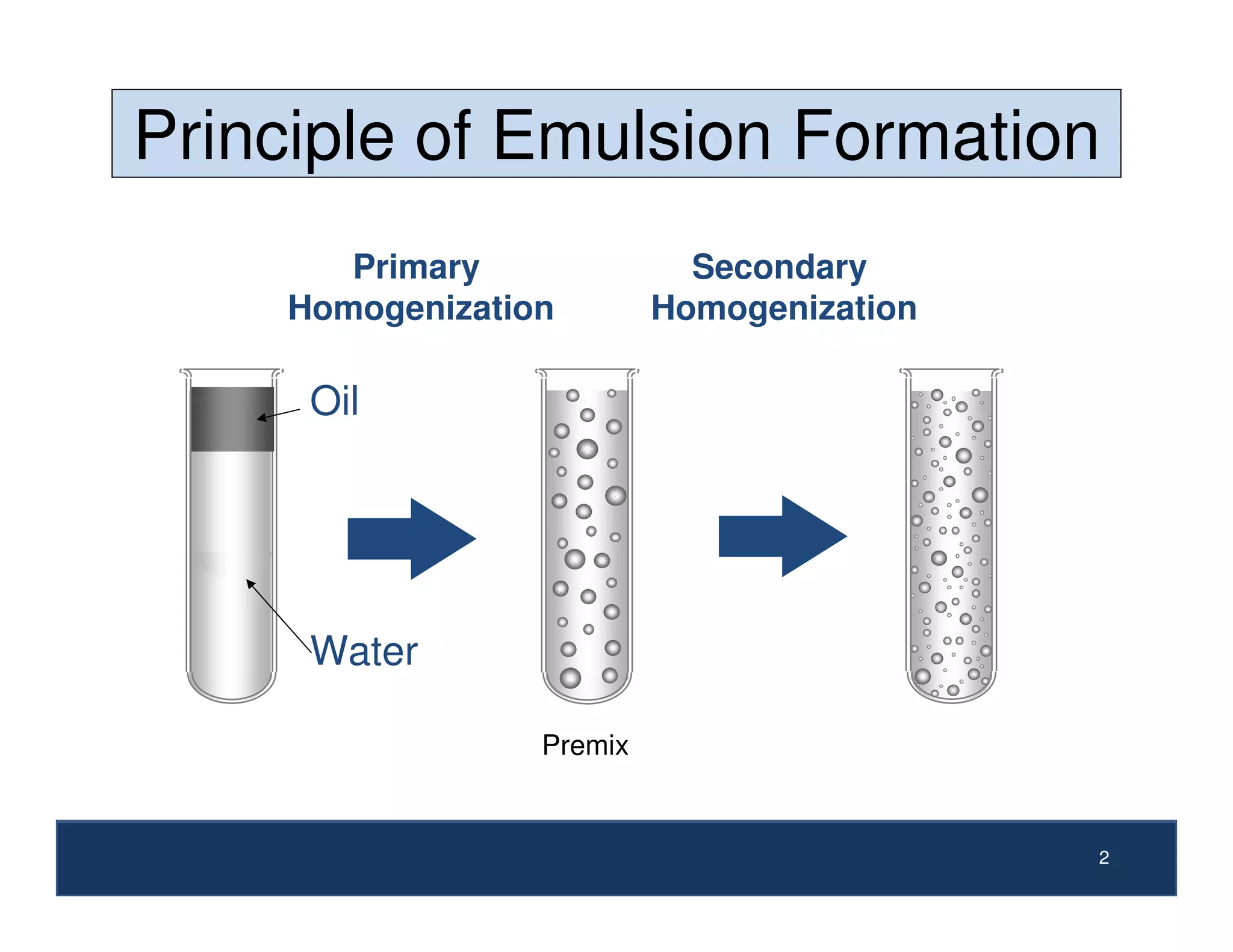

![Factors Affecting Droplet Size:

Emulsifier Type

0

1

2

3

4

5

0 5 10 15

Fast

Slow

Insufficient

Denaturation

Depends on:

Emulsifier Type

Emulsifier Conc.

Solution Conditions

Mechanical Device

Mean

Droplet

Diameter

[µm]

E [MJm-3]](https://image.slidesharecdn.com/5emulsionformation-220826023525-673736e0/75/5-Emulsion_Formation-pdf-14-2048.jpg)

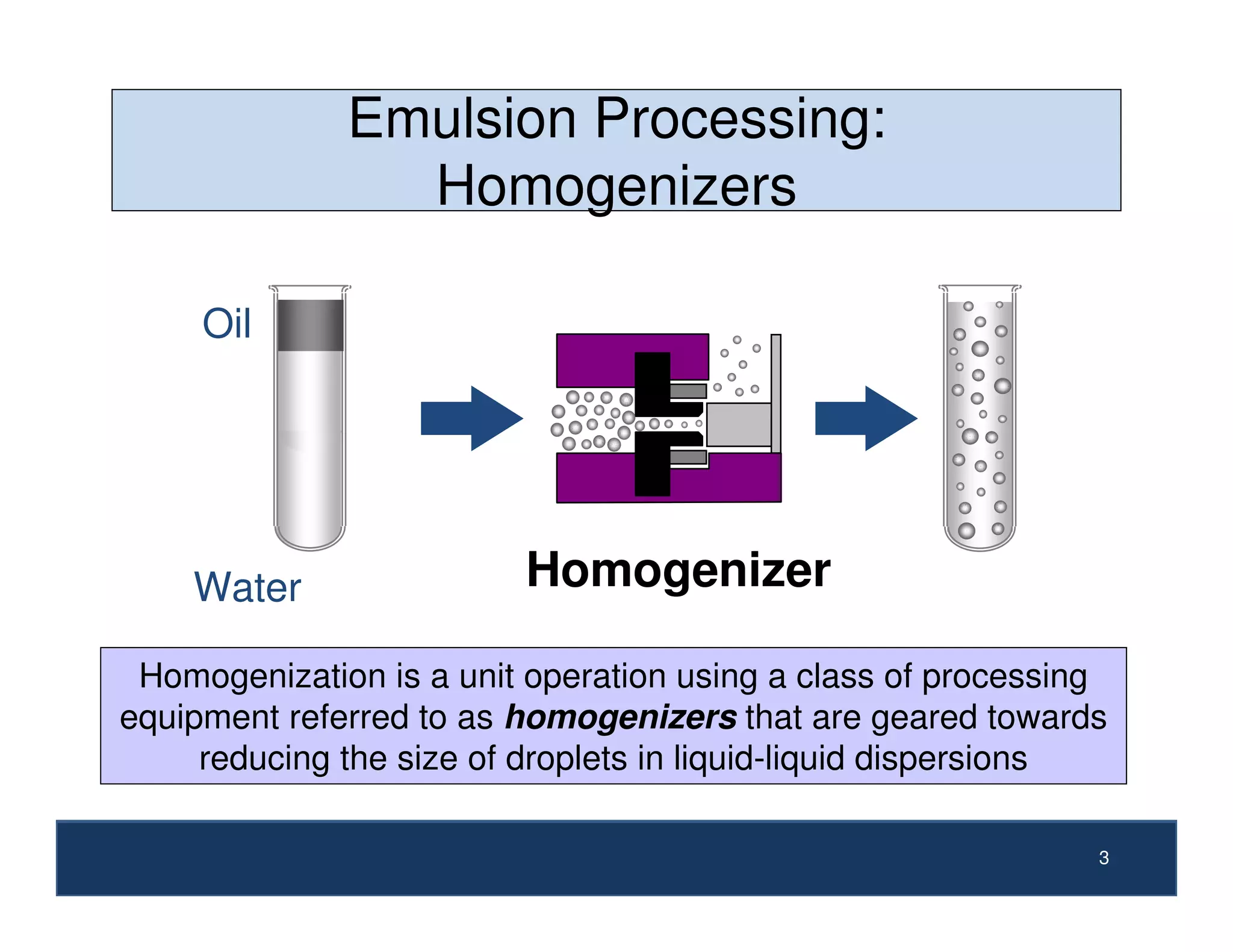

![Influence of Disperse and Continuous Phase

Viscosity

0

2

4

6

8

10

0.001 0.01 0.1 1 10

Viscosity Ratio:

Small droplets can only be

formed when viscosity

ratio of oil to aqueous

phase is between 0.05

and 5. It is therefore

important to control

viscosity ratio.

Laminar Flow Conditions, O/W

Emulsions, Fast Emulsifier

(Schubert and Armbruster, 1992)

ηd/ηc

Mean

Droplet

Diameter

[µm]](https://image.slidesharecdn.com/5emulsionformation-220826023525-673736e0/75/5-Emulsion_Formation-pdf-28-2048.jpg)