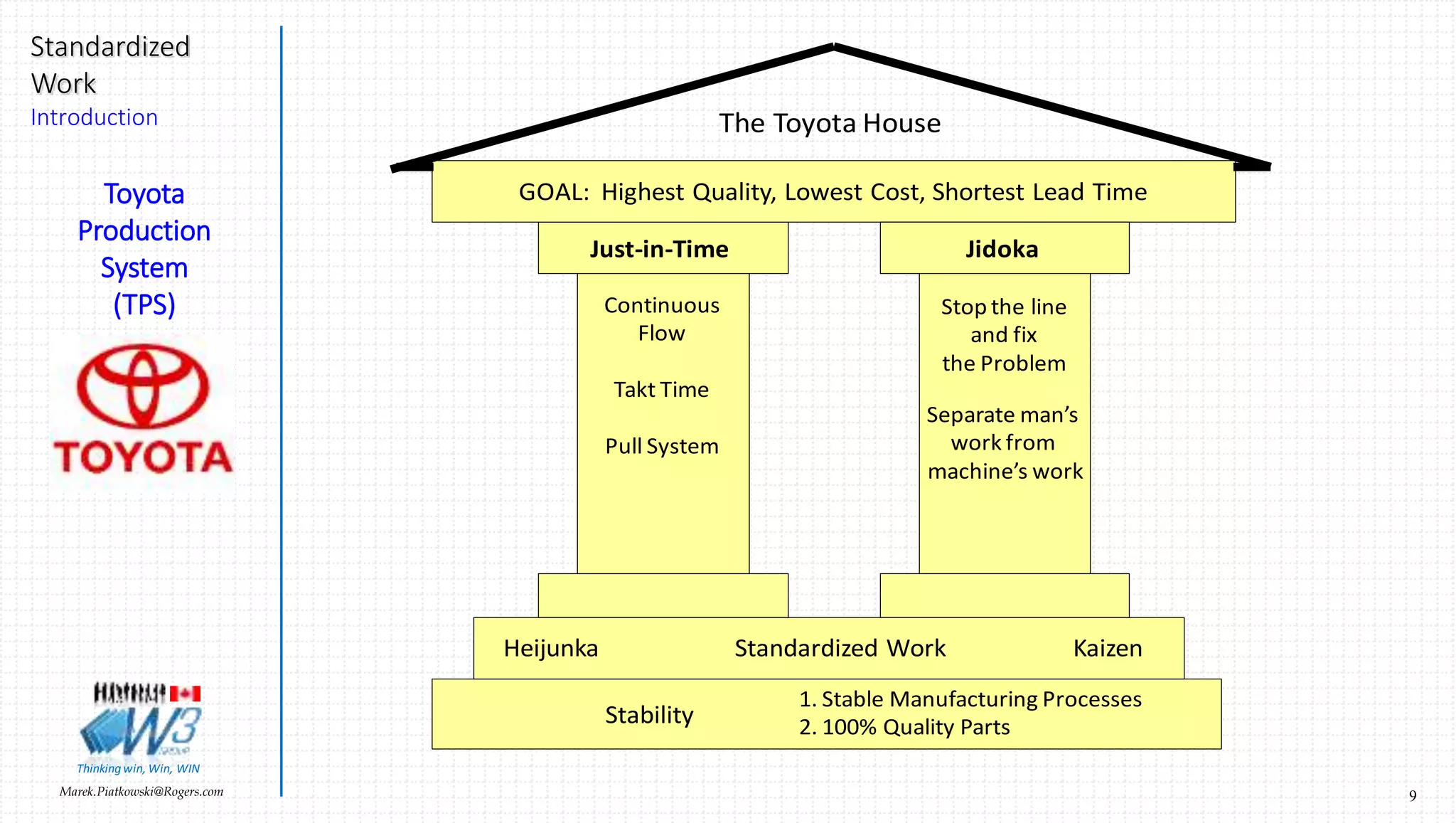

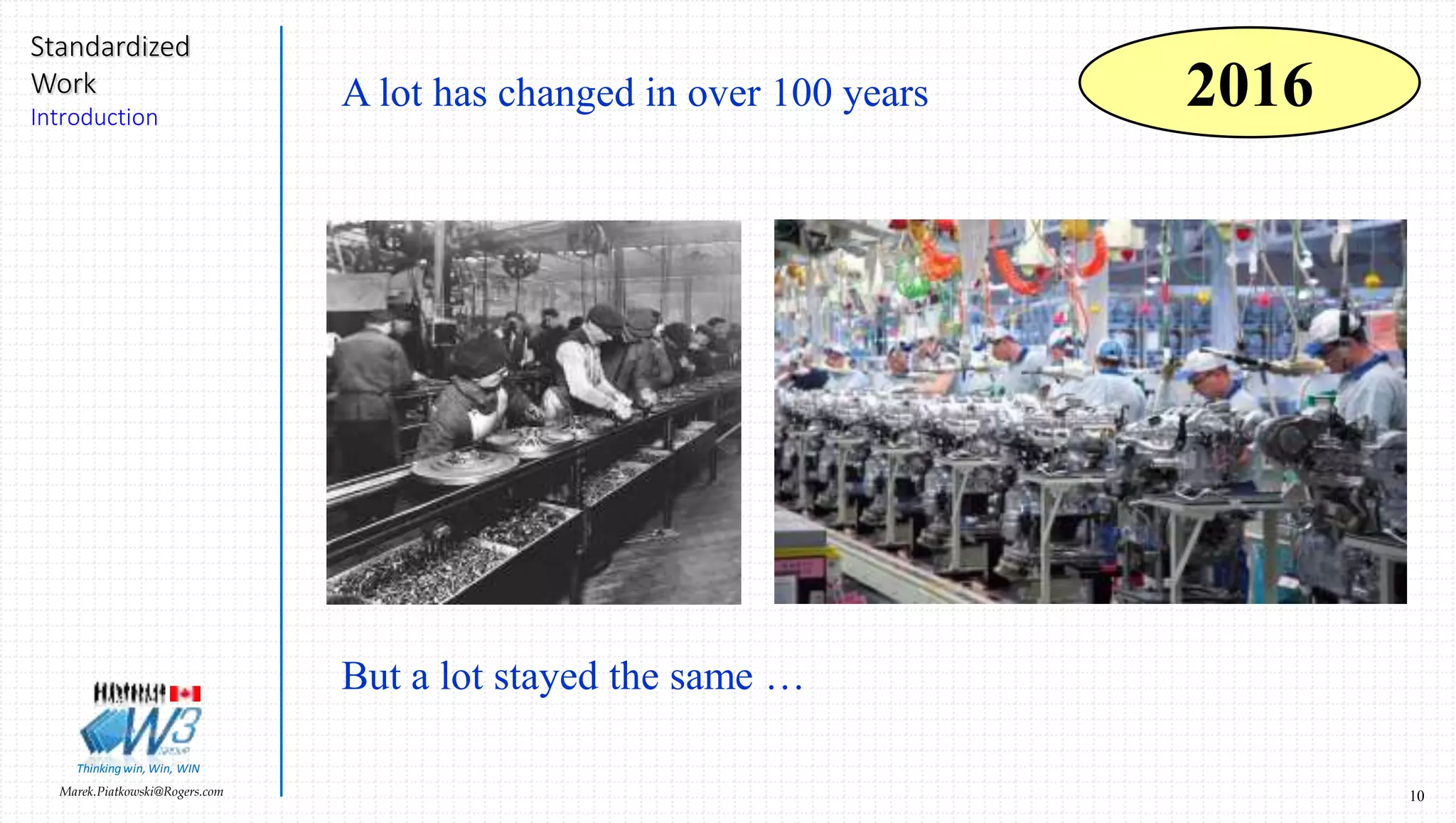

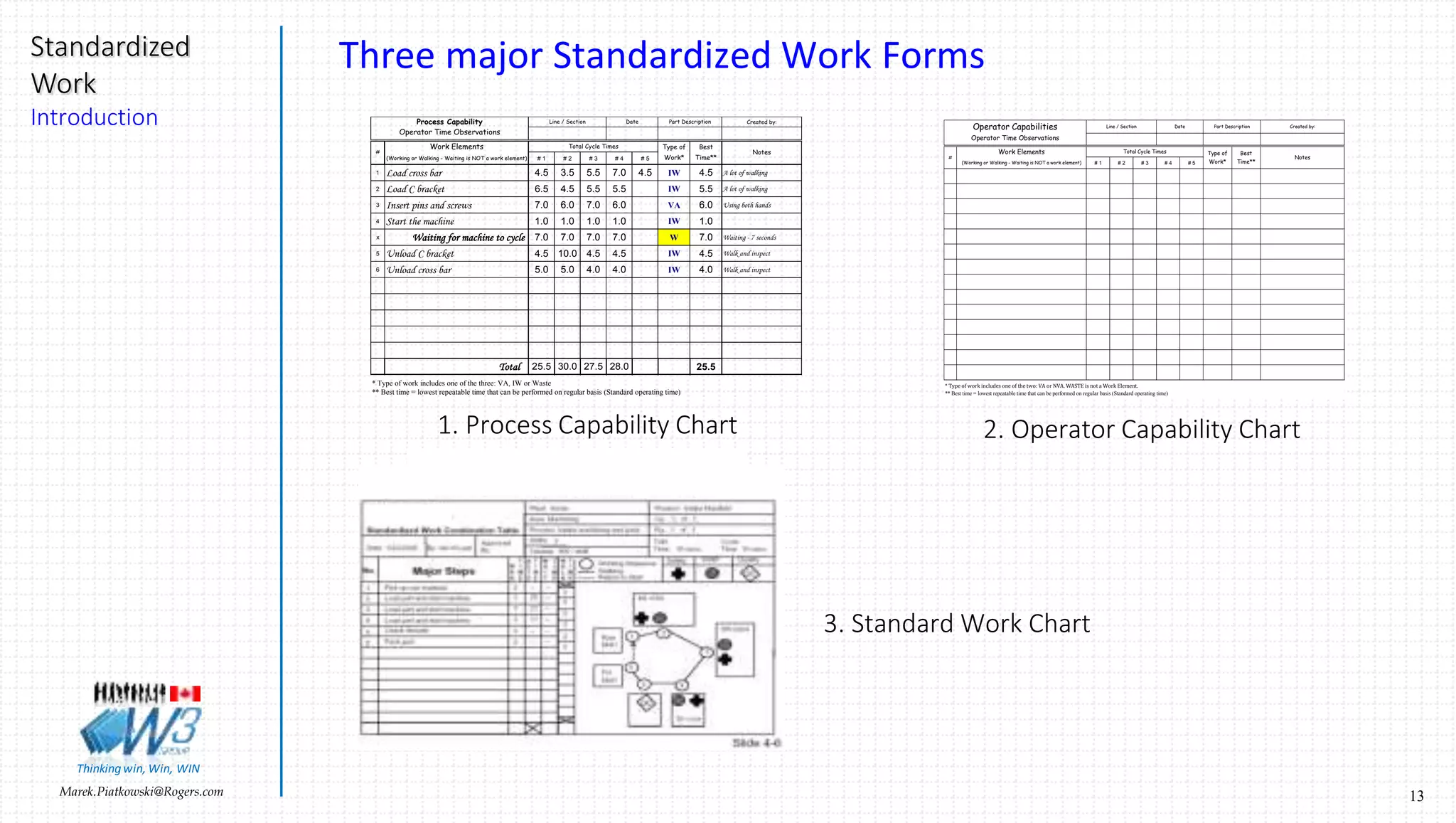

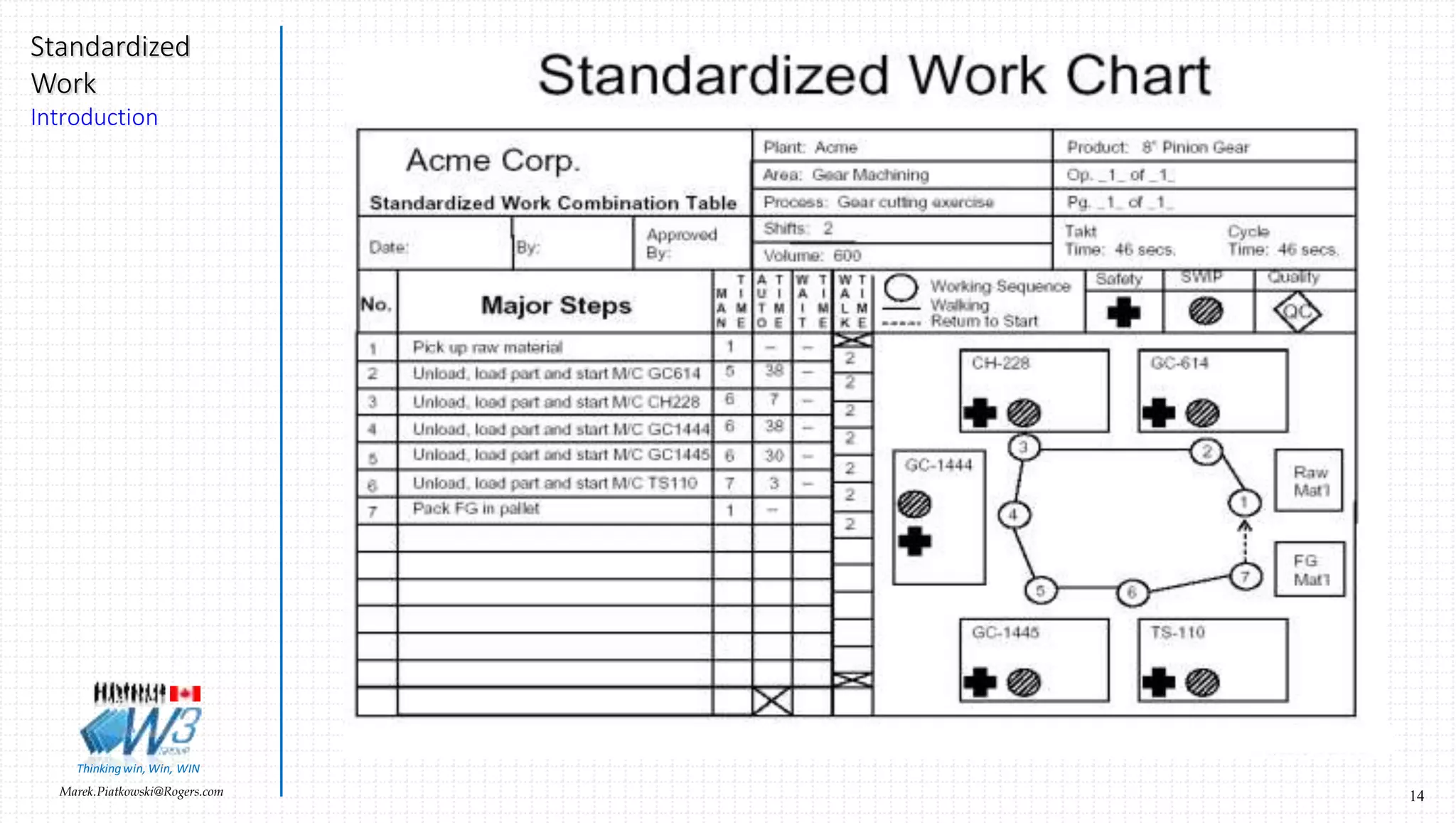

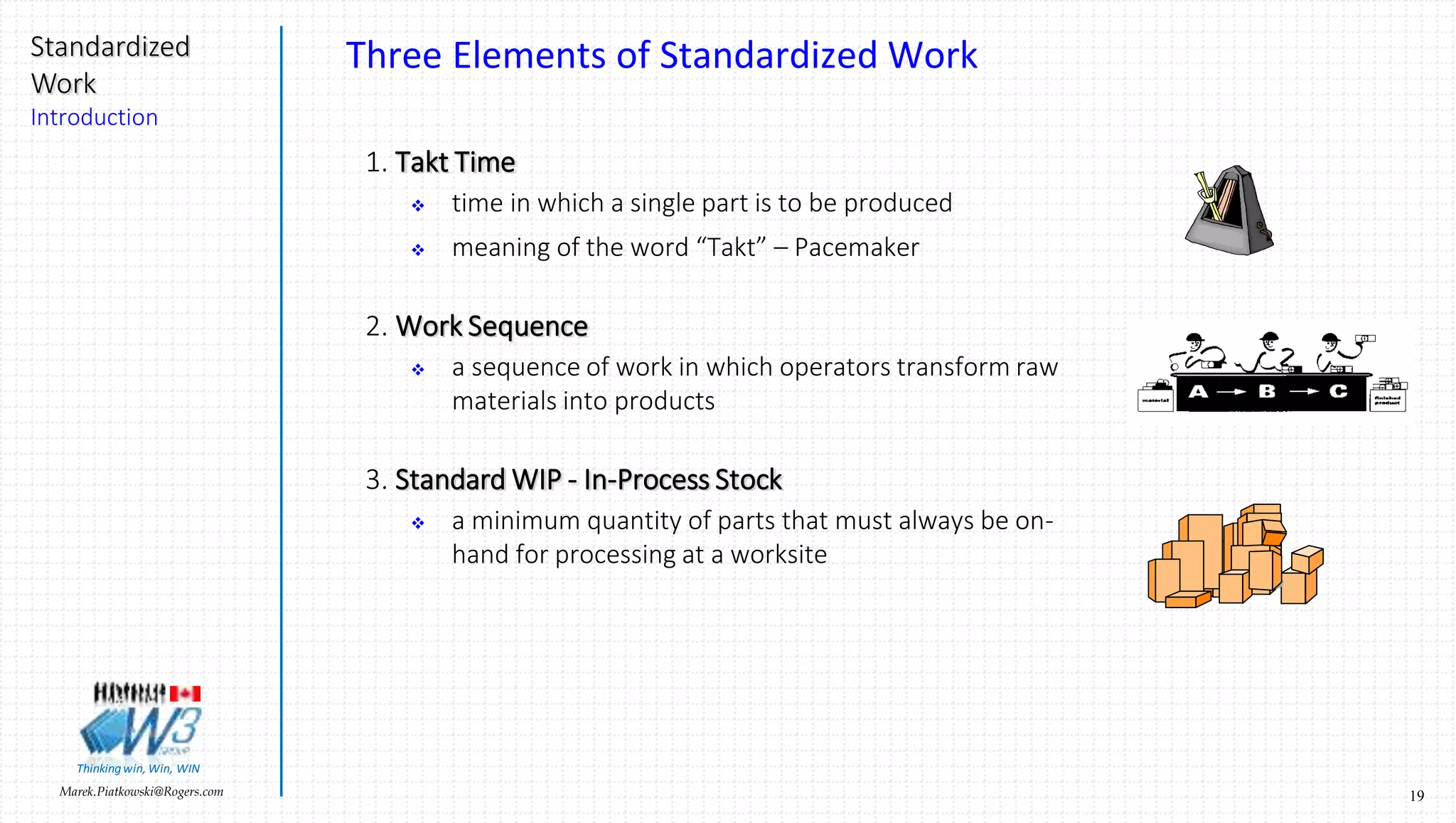

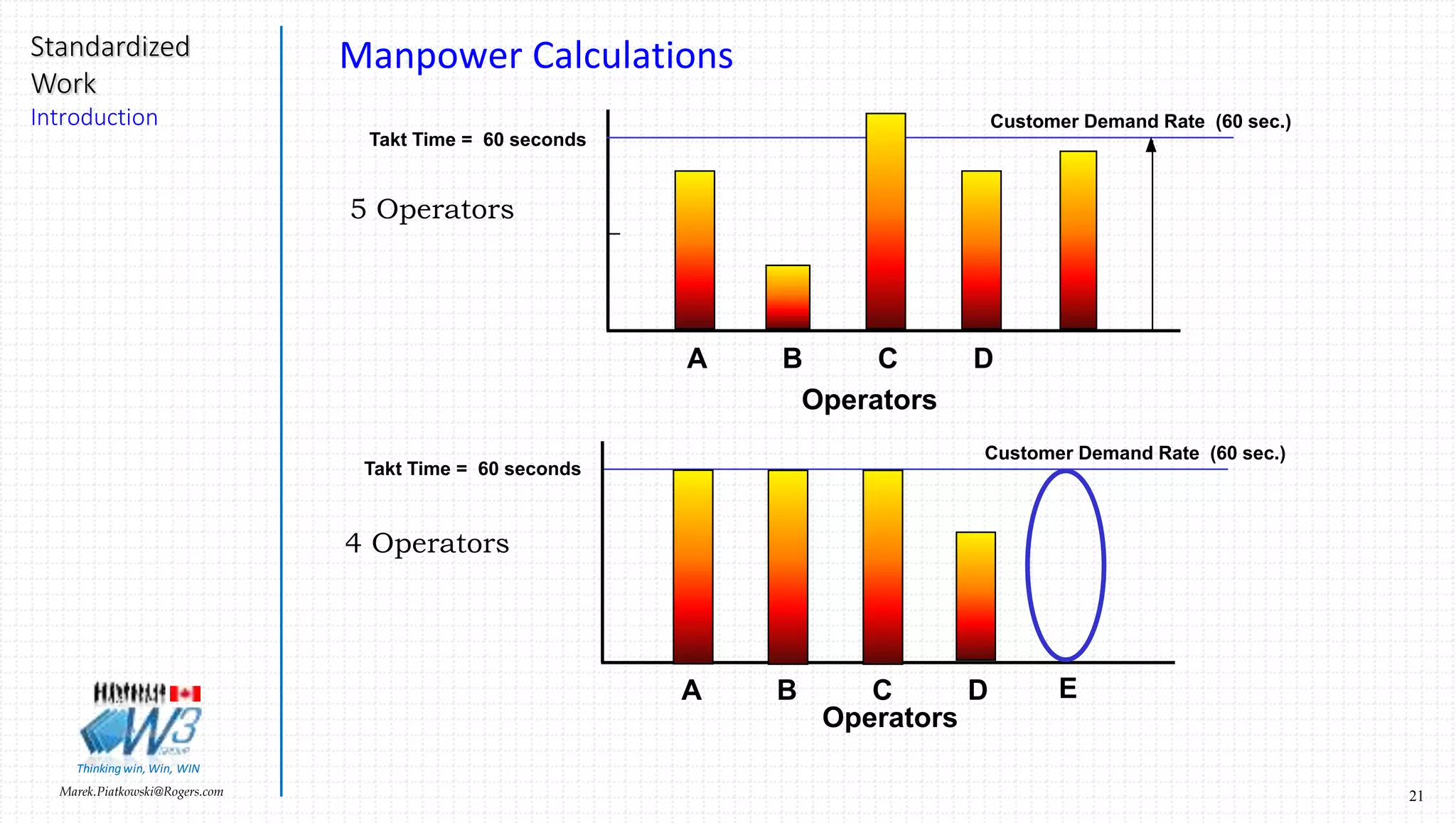

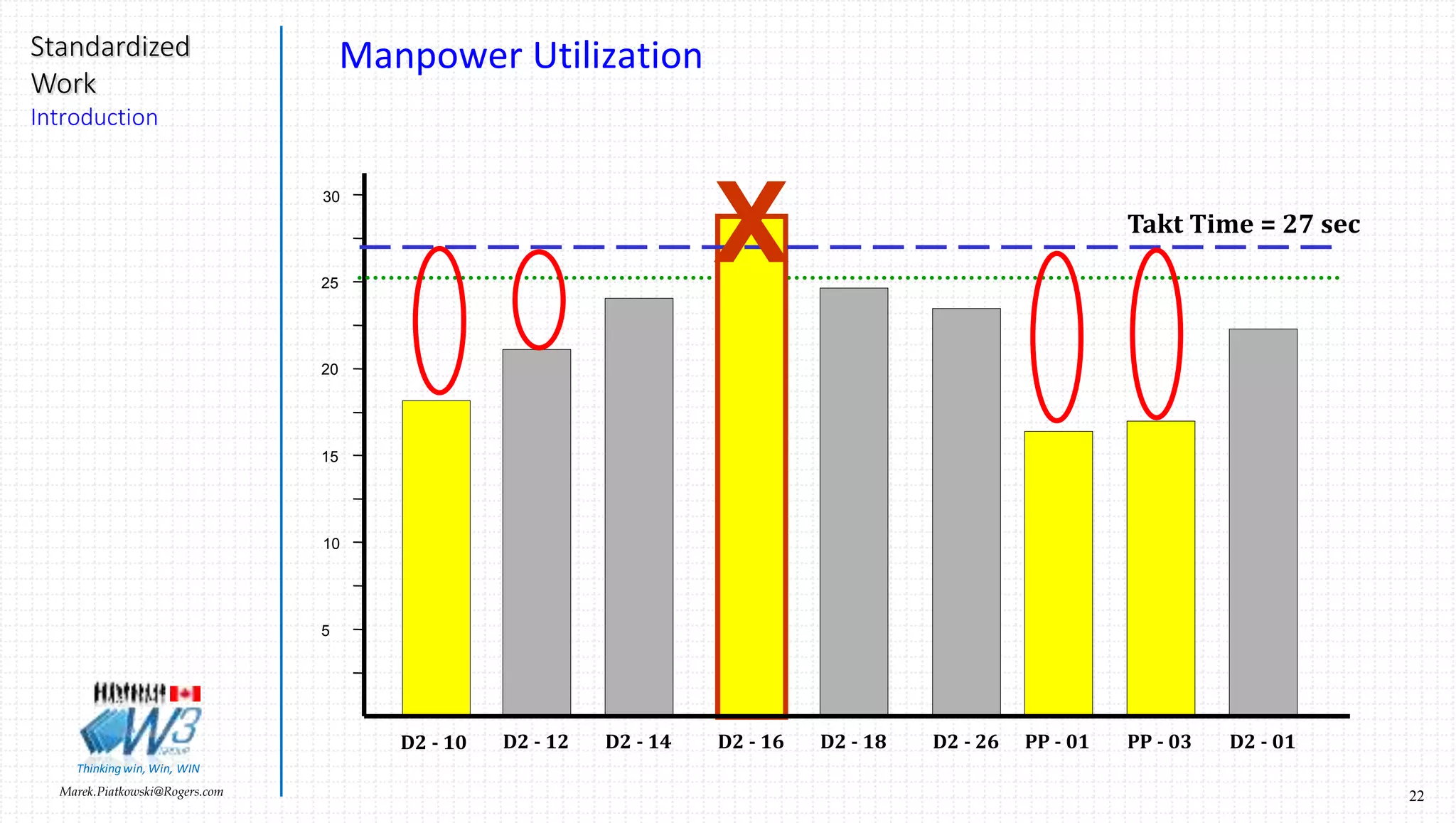

The document provides an introduction to standardized work. It discusses how standardized work was developed based on principles from Henry Ford's assembly line and mass production techniques. The purpose of standardized work is to document the most efficient work methods and use it as a baseline for continuous improvement. It defines the work sequence, cycle time, and standard in-process inventory levels. Benefits include eliminating waste, easier problem identification, and establishing a flexible manufacturing system.