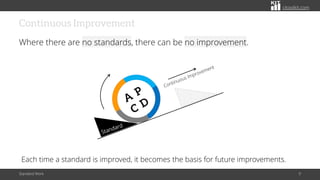

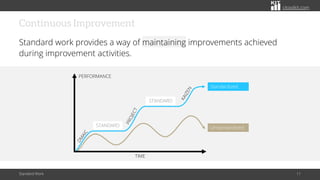

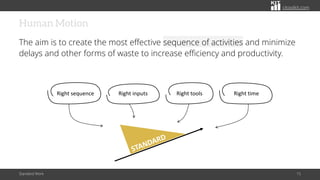

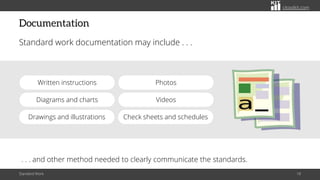

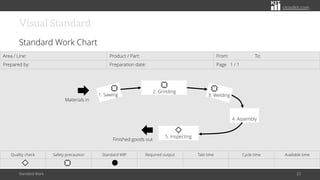

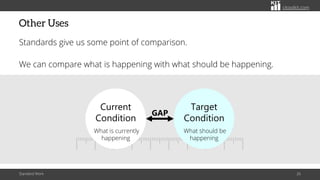

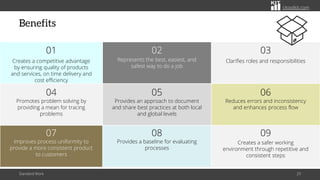

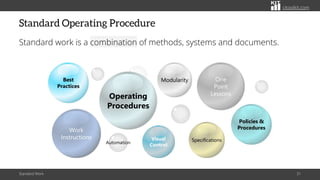

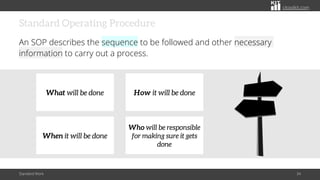

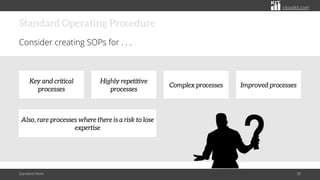

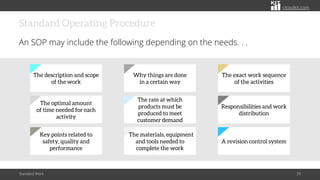

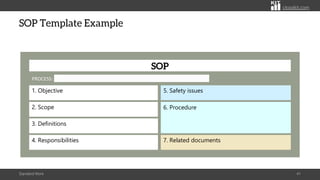

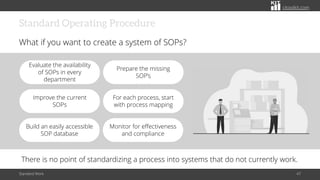

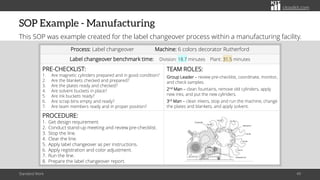

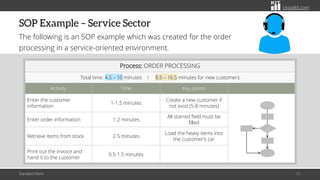

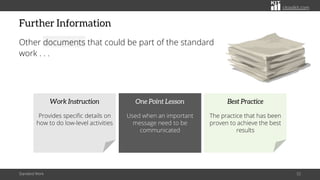

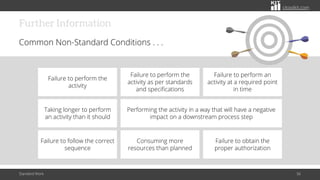

The document defines standard work as a method to achieve consistency and reliability in processes, emphasizing its importance in lean practices. It asserts that standardized processes reduce variability and improve efficiency, forming a foundation for continuous improvement and training. Furthermore, the text outlines the necessary components for effective standard work documentation and the role of standard operating procedures (SOPs) in maintaining consistency and quality across various operations.