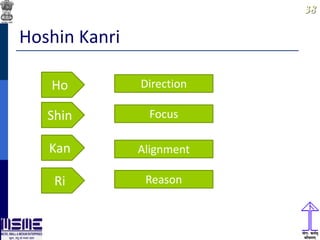

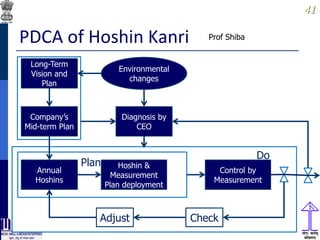

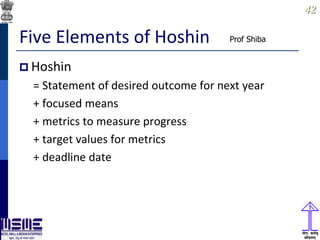

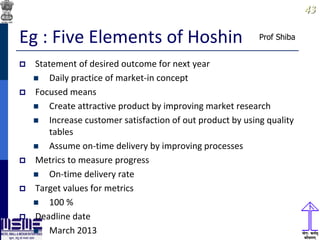

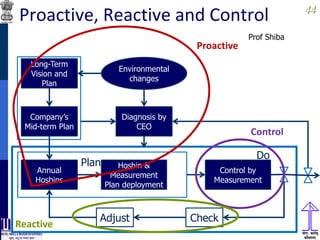

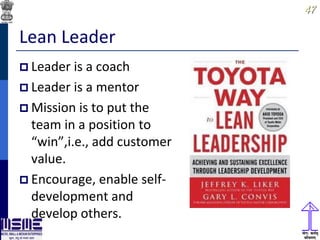

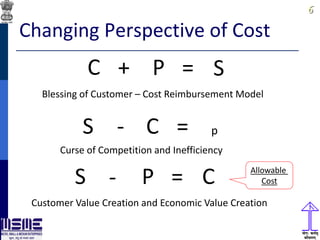

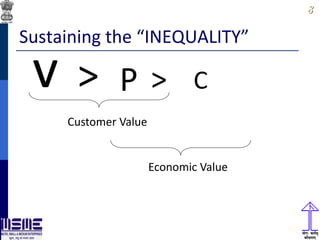

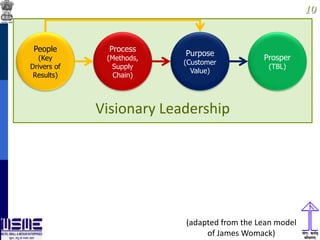

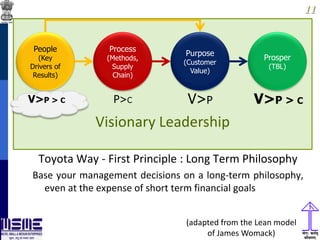

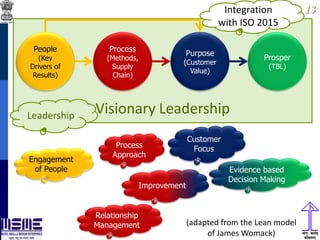

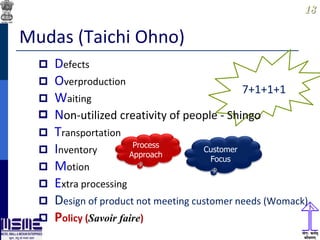

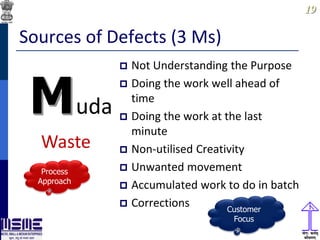

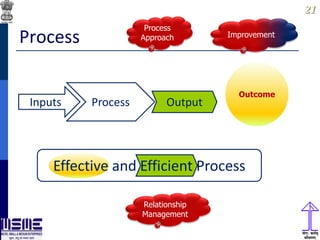

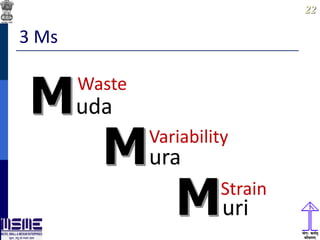

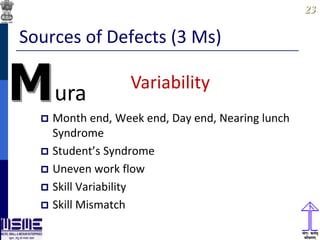

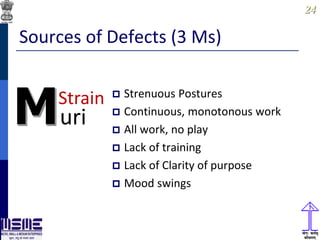

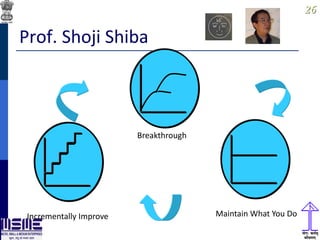

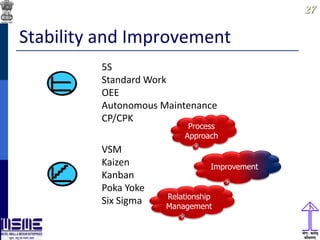

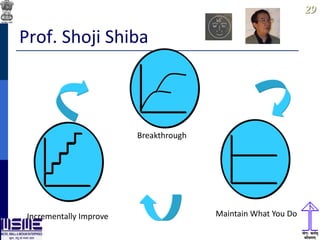

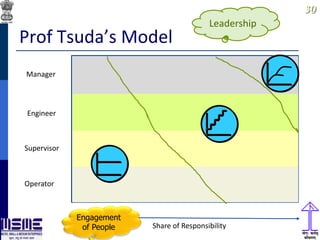

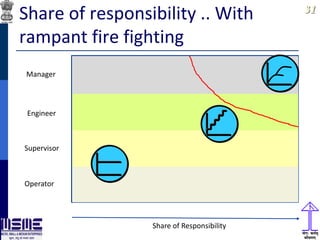

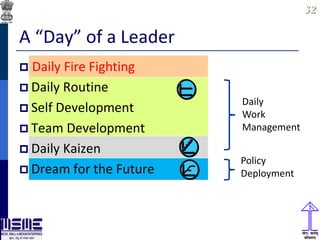

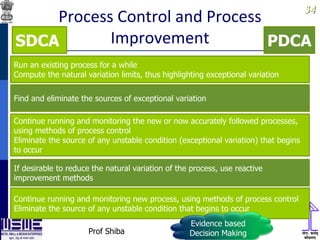

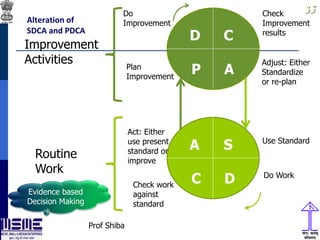

This document discusses lean thinking and leadership. It covers topics like changing cost perspectives in lean from focusing on costs to customer value. It emphasizes sustaining inequality between customer value and costs. The document presents models for lean thinking alignment with aspects like purpose, process, people and prosperity. It discusses integrating lean with quality management standards. Other topics covered include identifying types of waste, using tools like 5S, standard work and visual management. The document emphasizes leadership aspects such as engaging people, evidence-based decision making and developing a long term philosophy. It presents models for process control and improvement as well as aligning activities through hoshin kanri for business breakthroughs.

![3636Building

Blocks of

DWM™

Standard Work

Visual

Manage-

ment

SDCA/

PDCA

Cycle

Daily

Kaizen

Defined Zonal Ownership

MP/CP Aligned with KPIs

Communication

KPIs Aligned with Policy Deployment

DWM aligned to

Customer Value

[ Control ] [ Improvement ]

Evidence based

Decision Making

Customer

Focus

Leadership Engagement

of People

Process

Approach

Improvement

Relationship

Management](https://image.slidesharecdn.com/leanthinkingthrudwm-160311142029/85/Lean-Thinking-and-Daily-Work-Management-36-320.jpg)