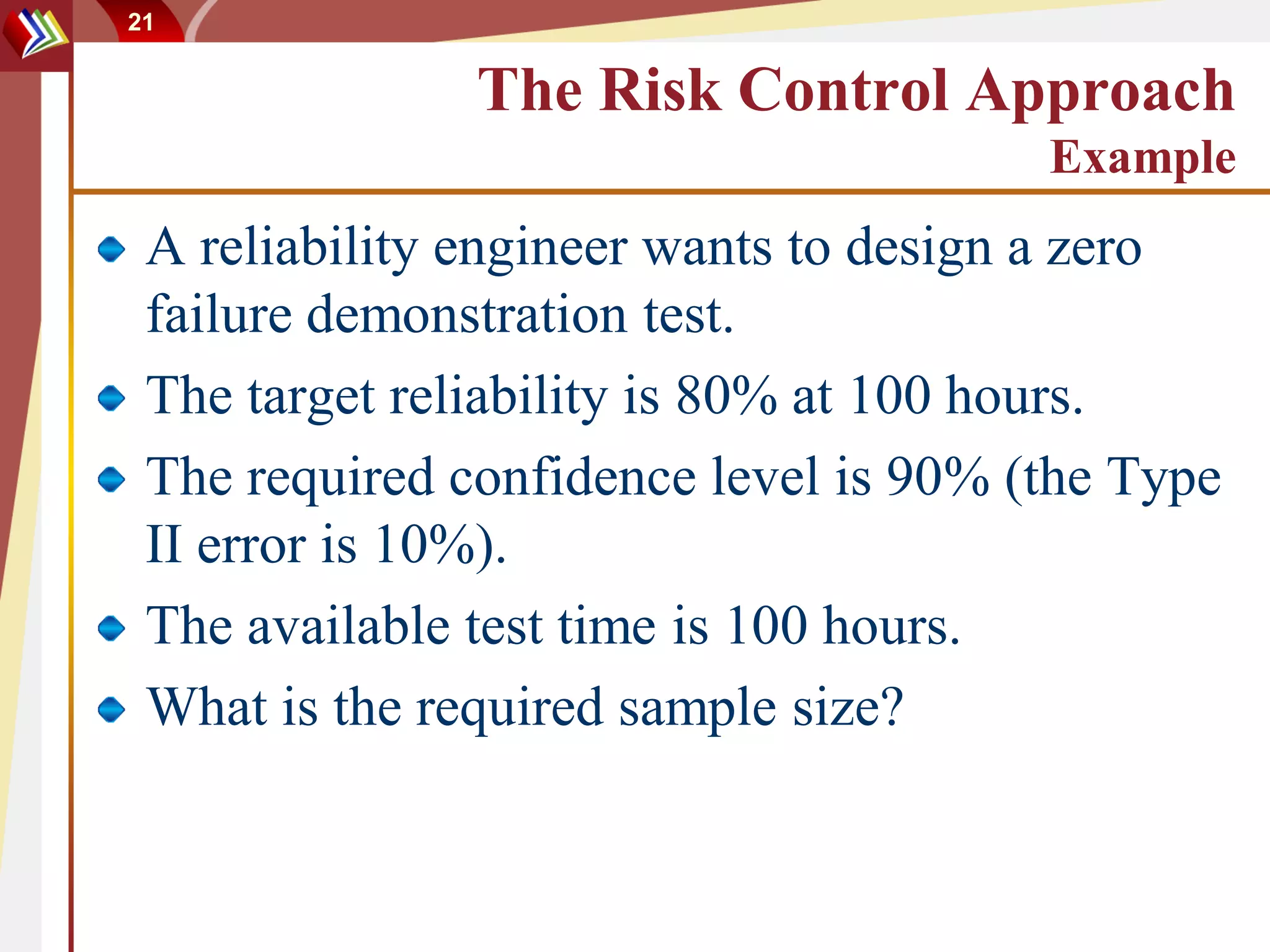

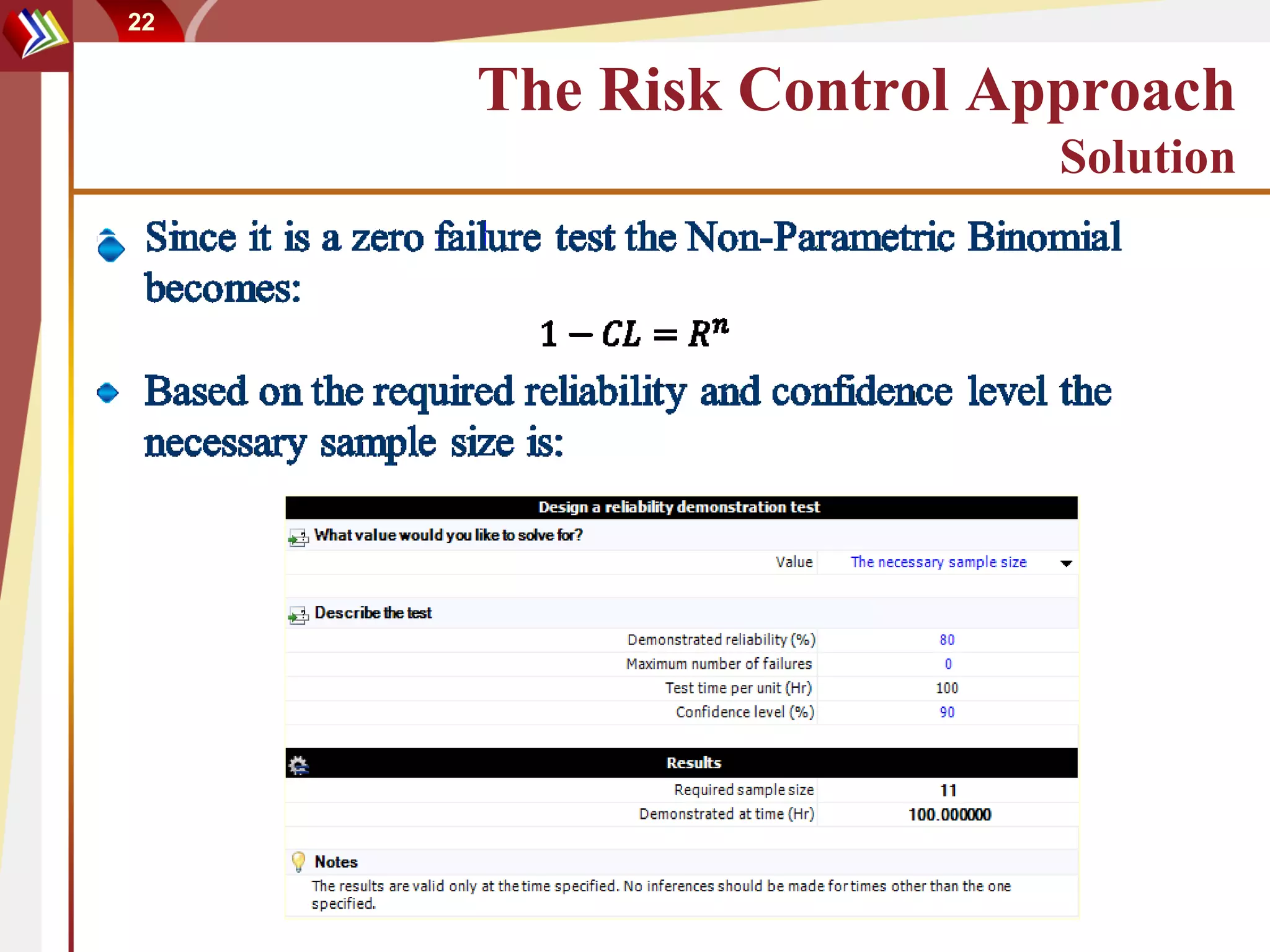

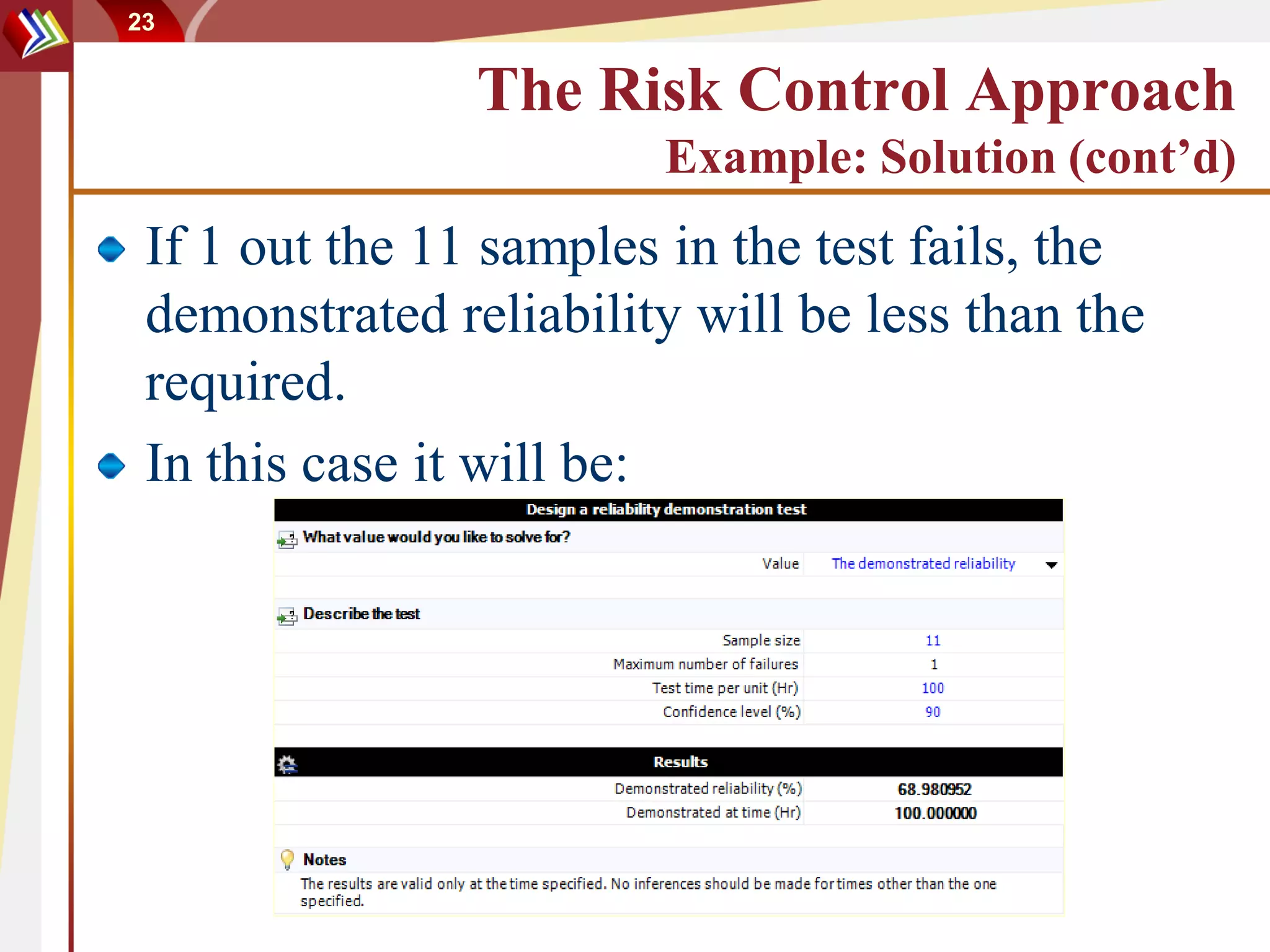

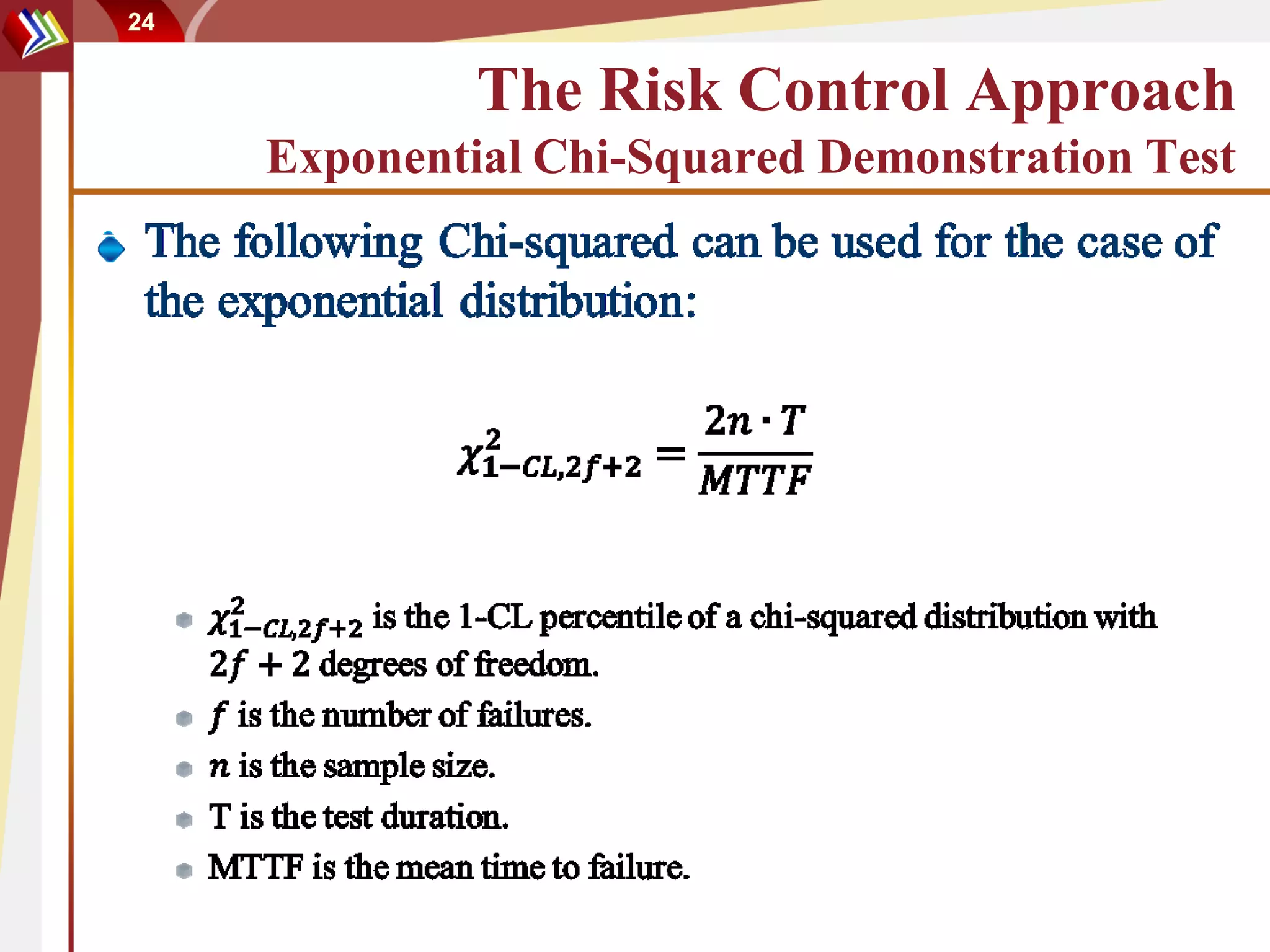

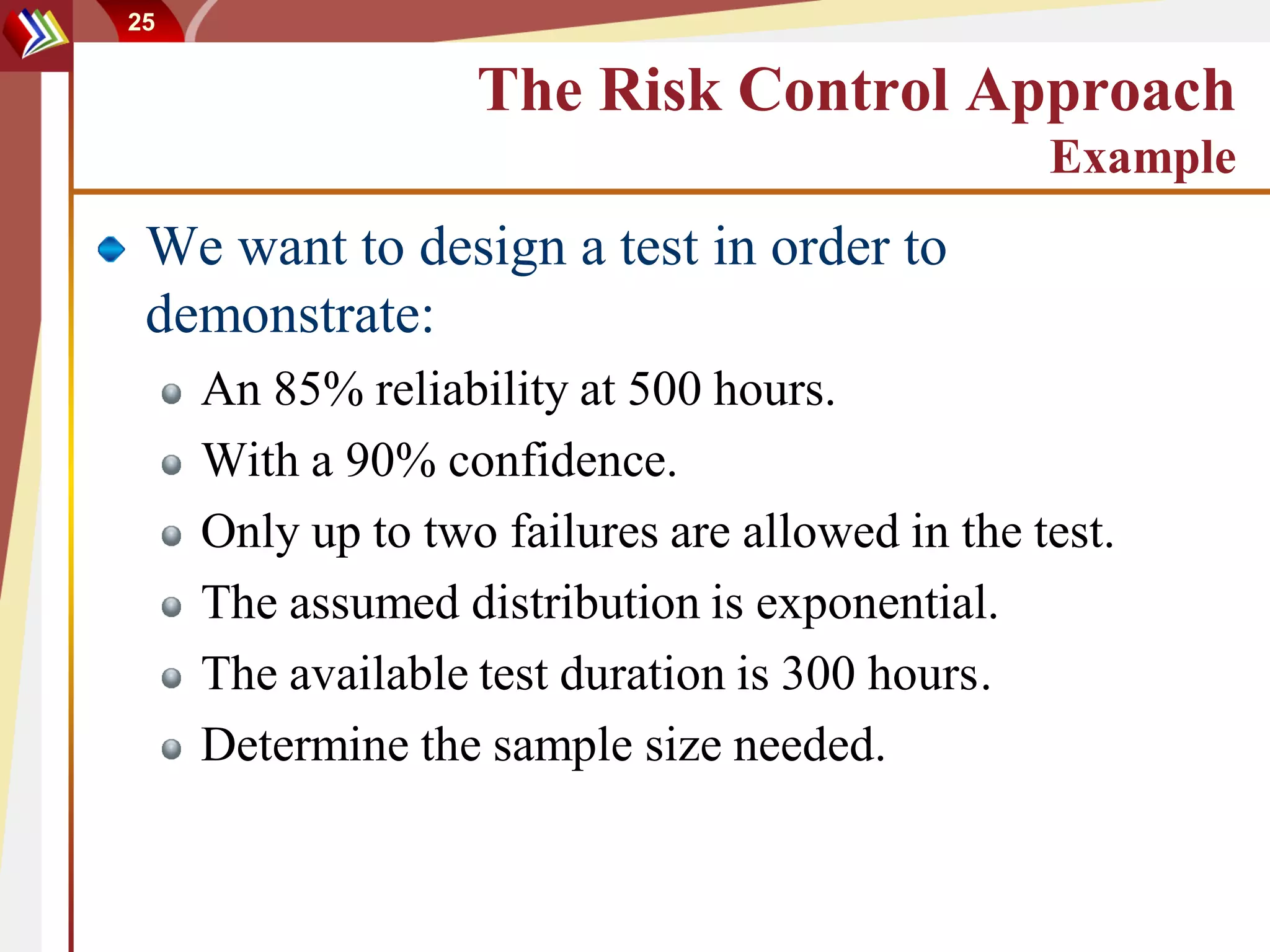

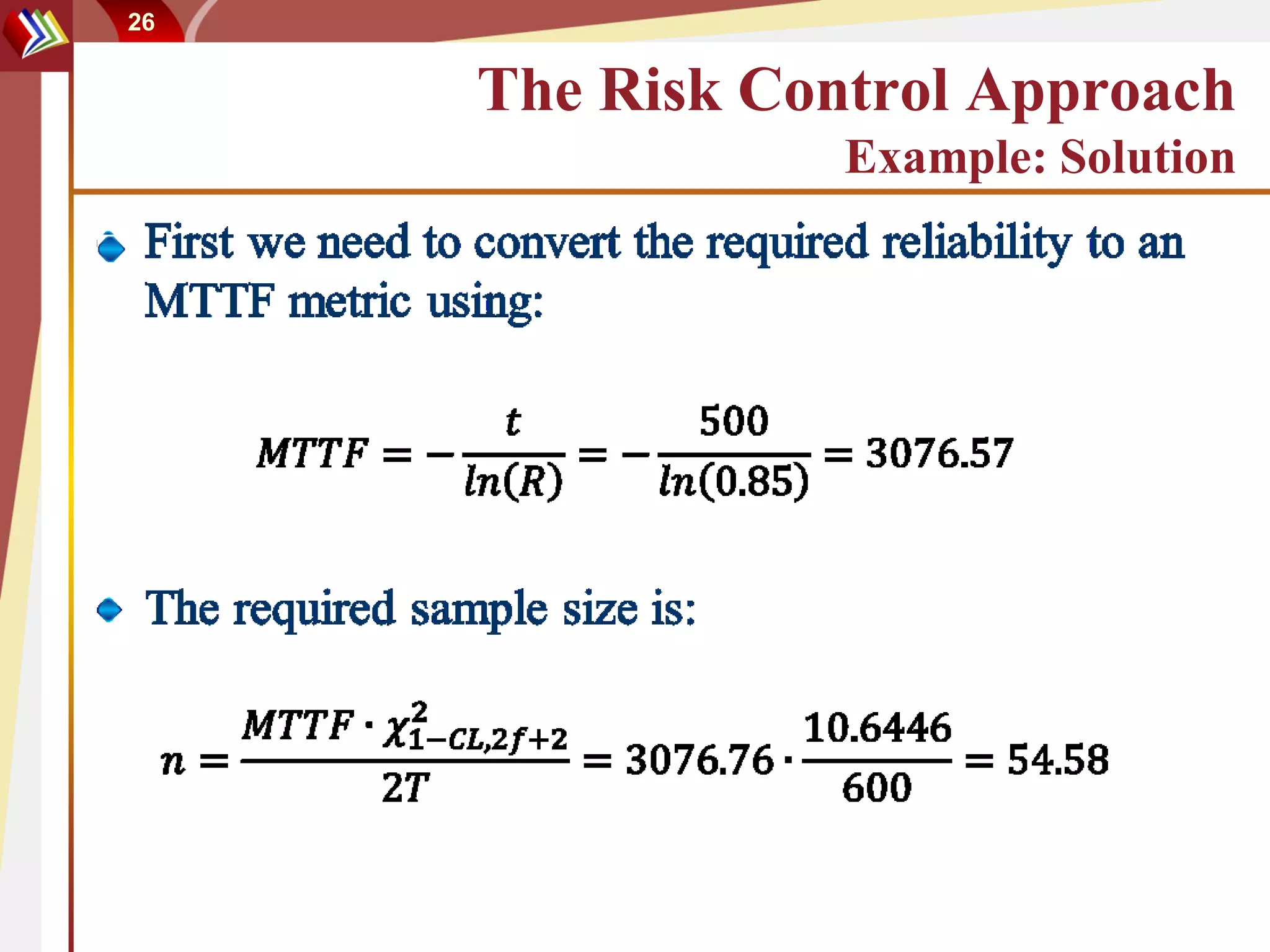

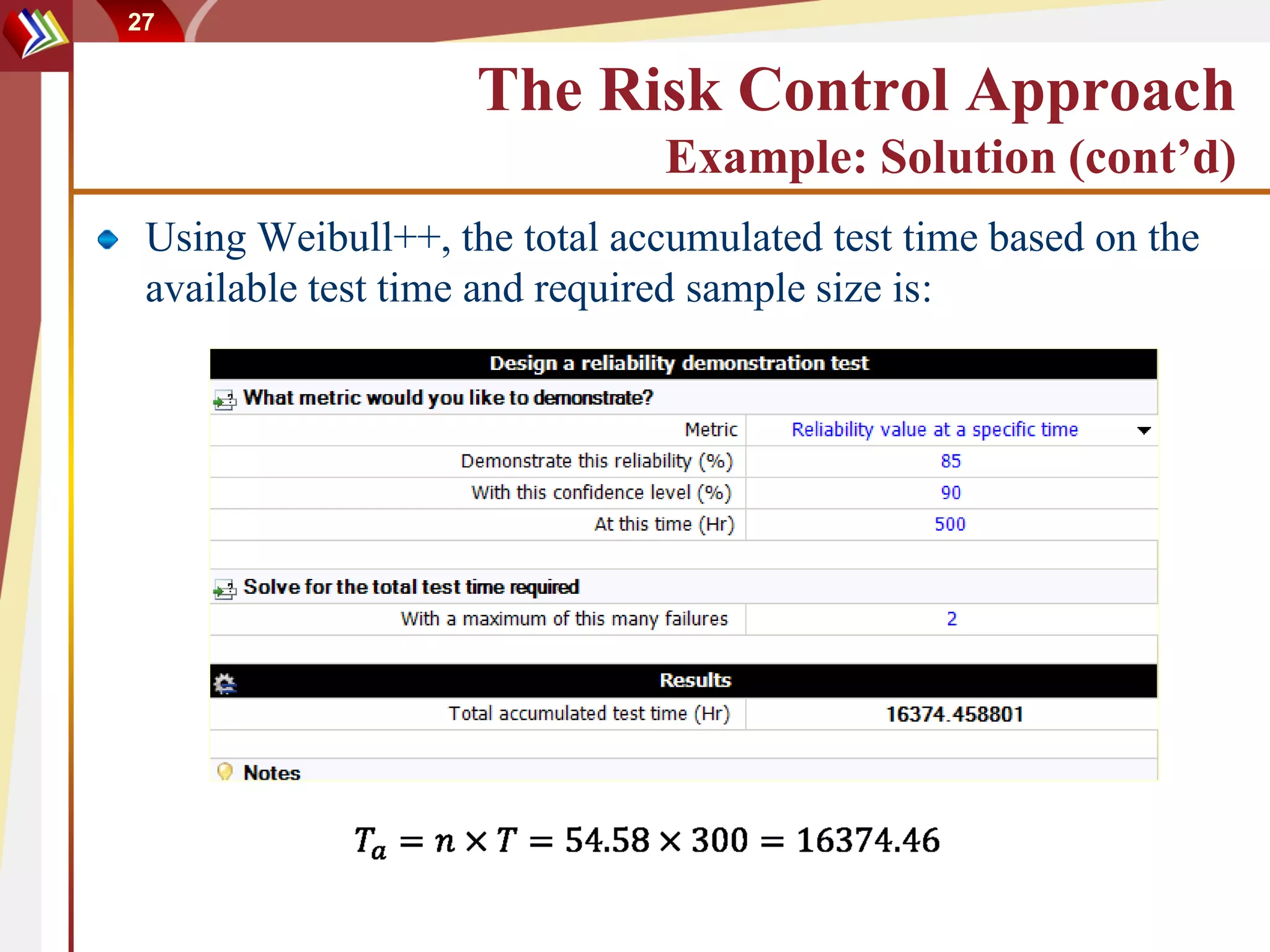

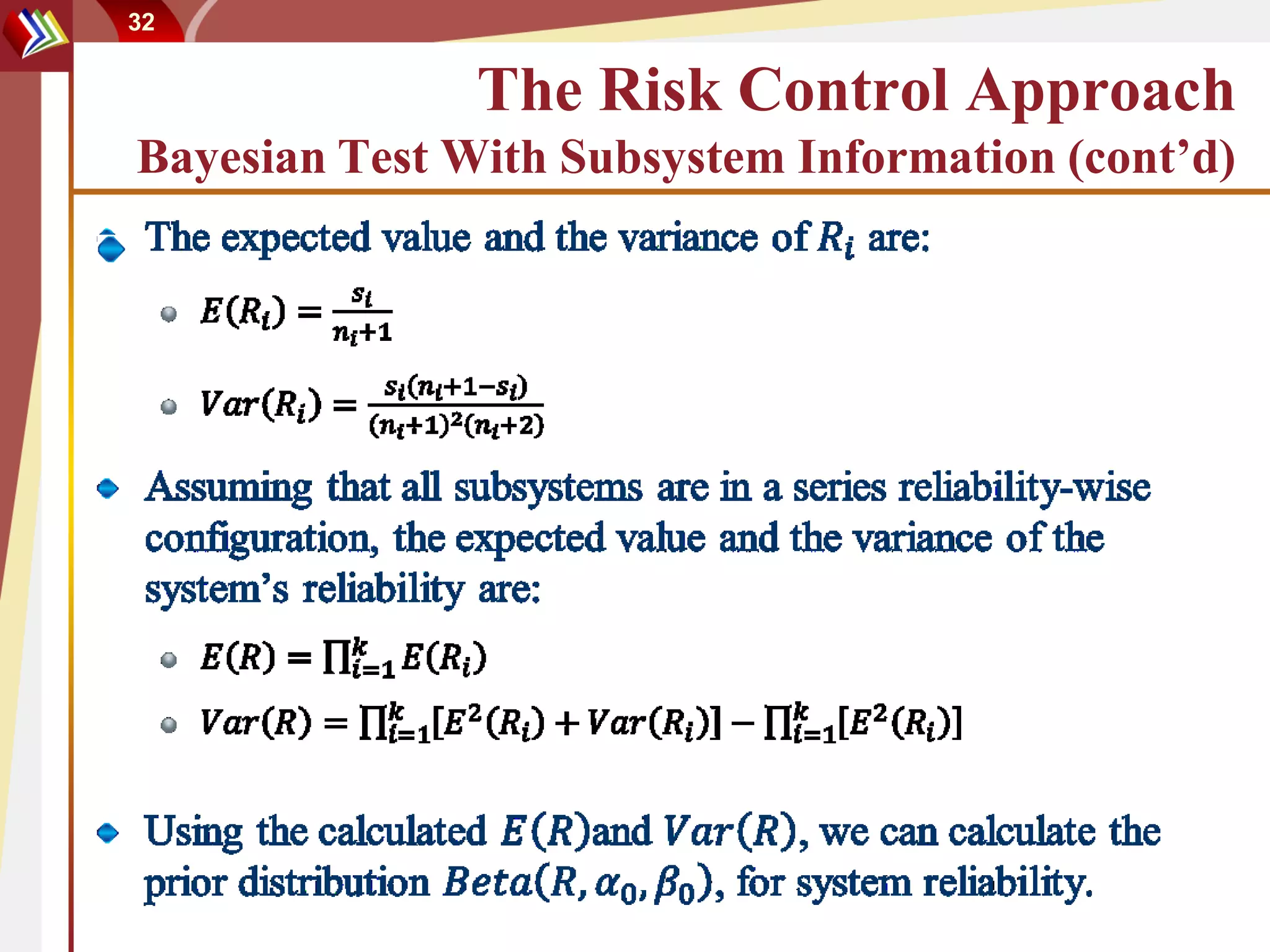

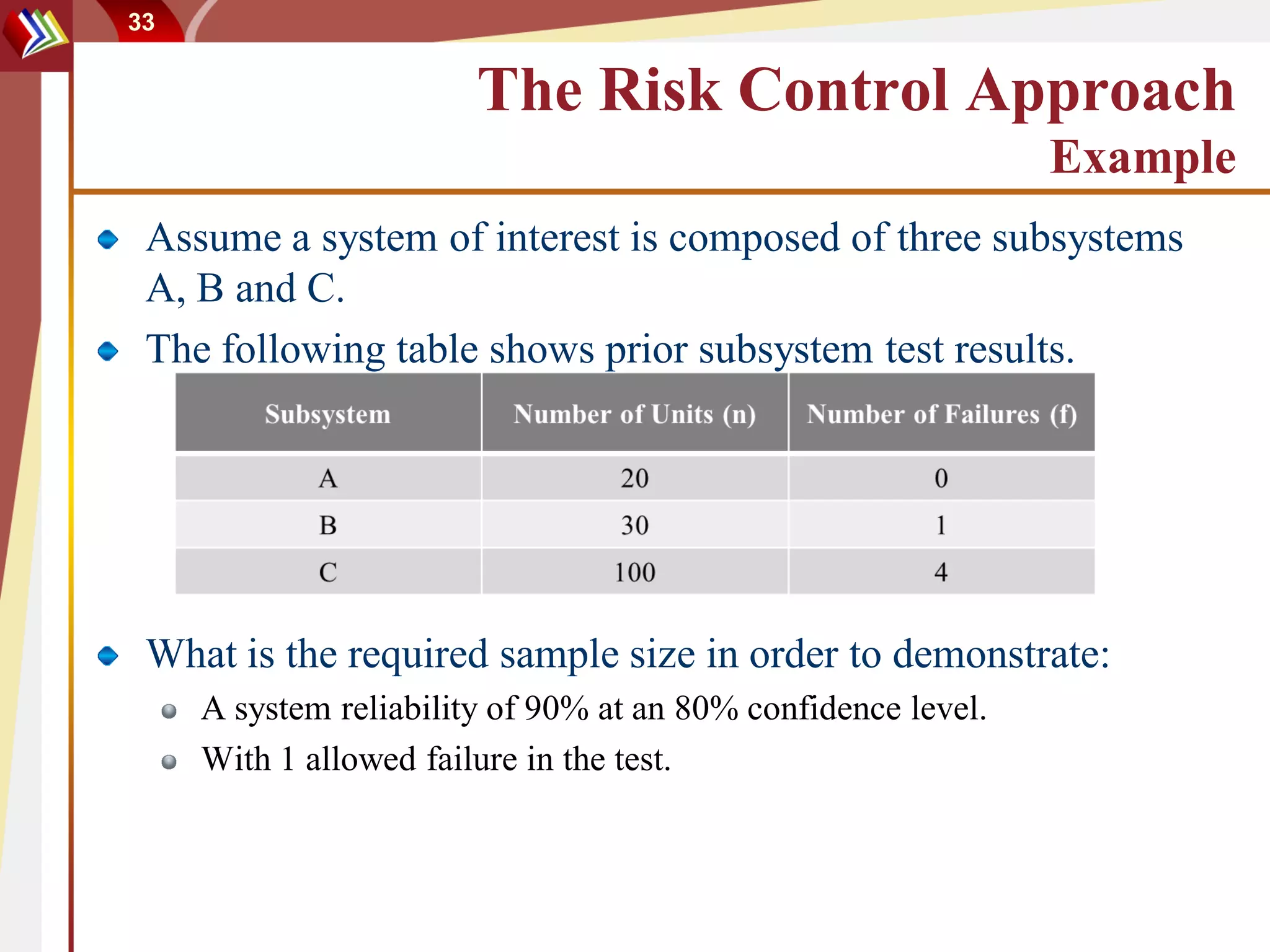

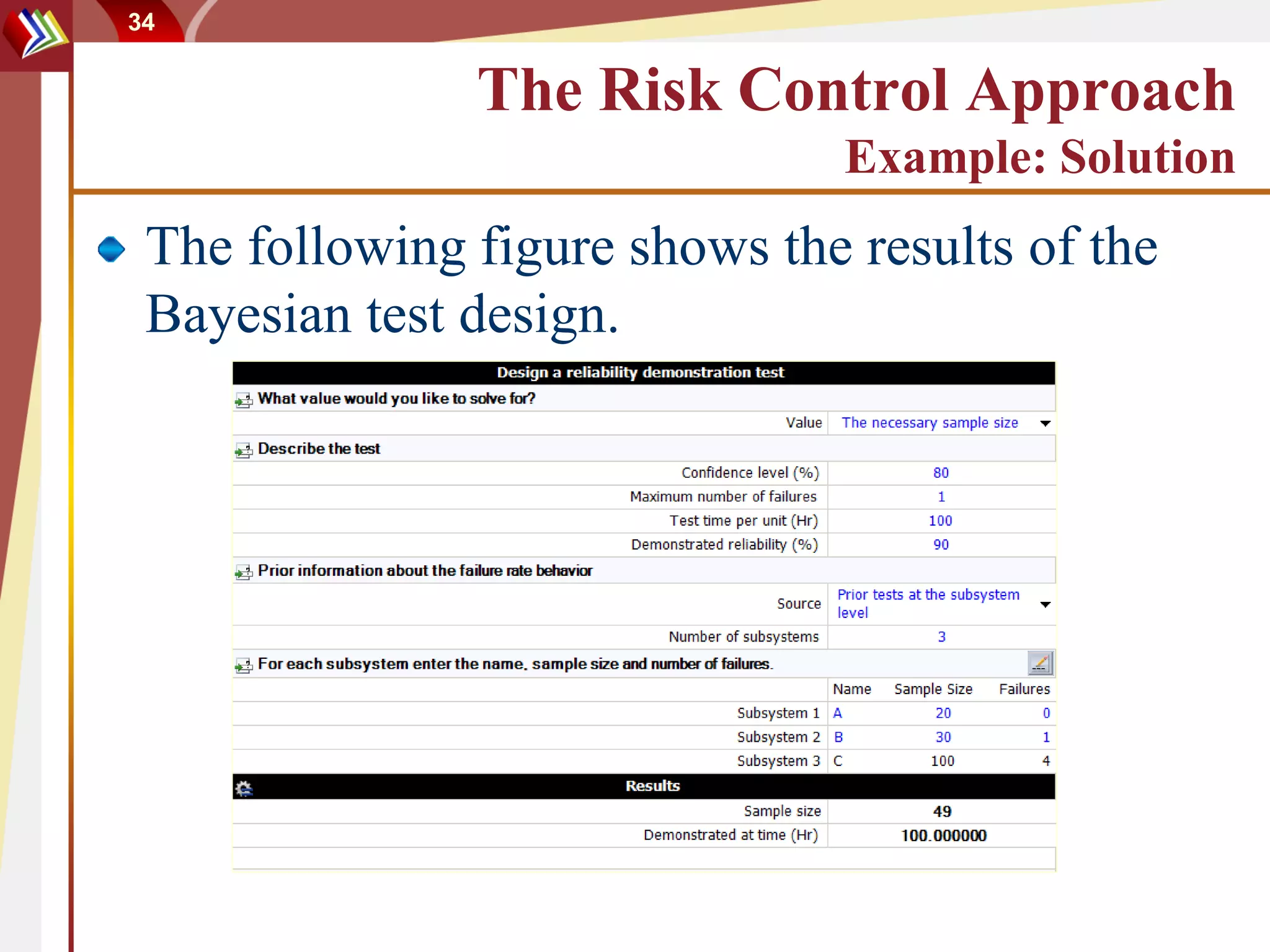

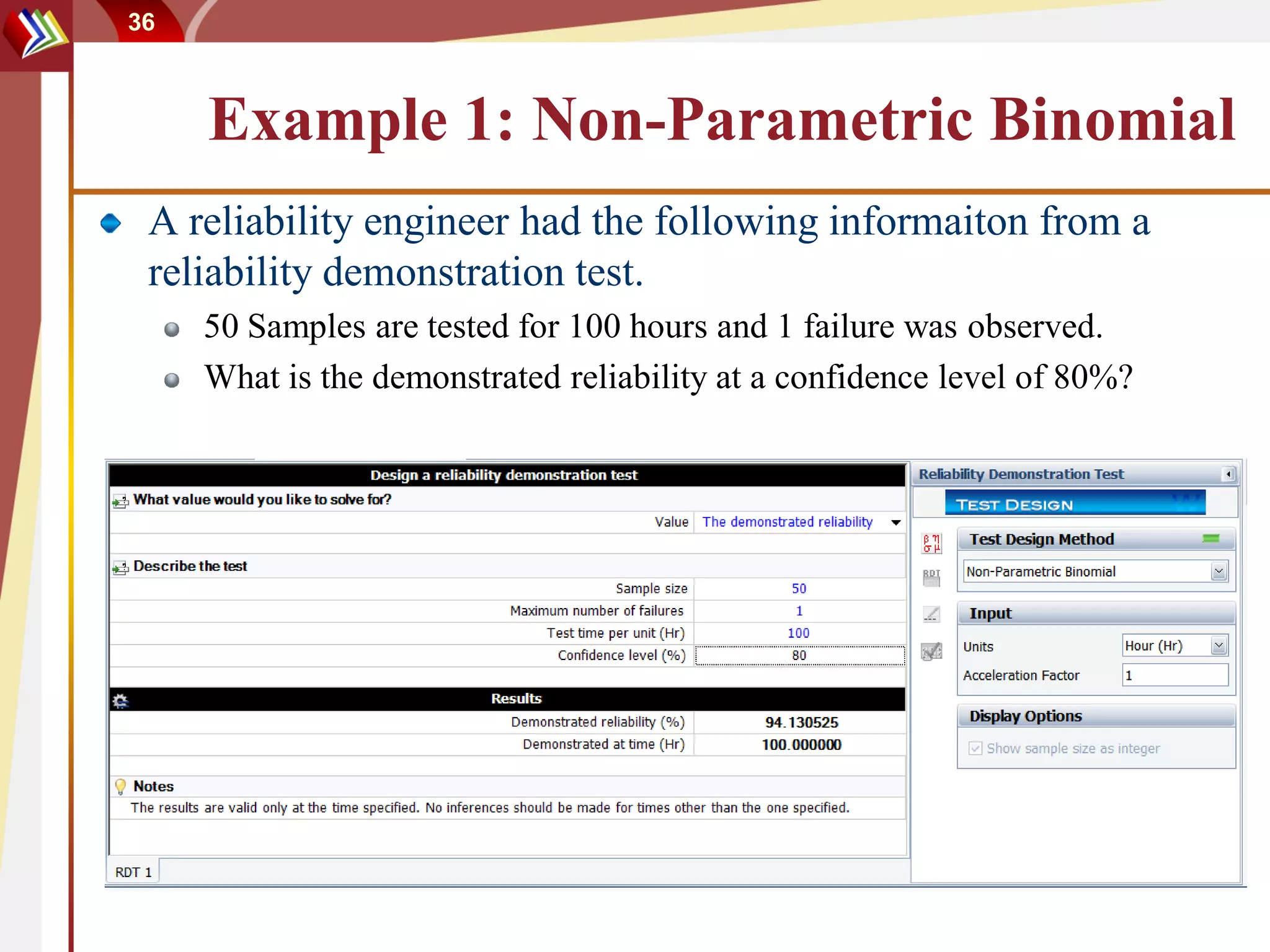

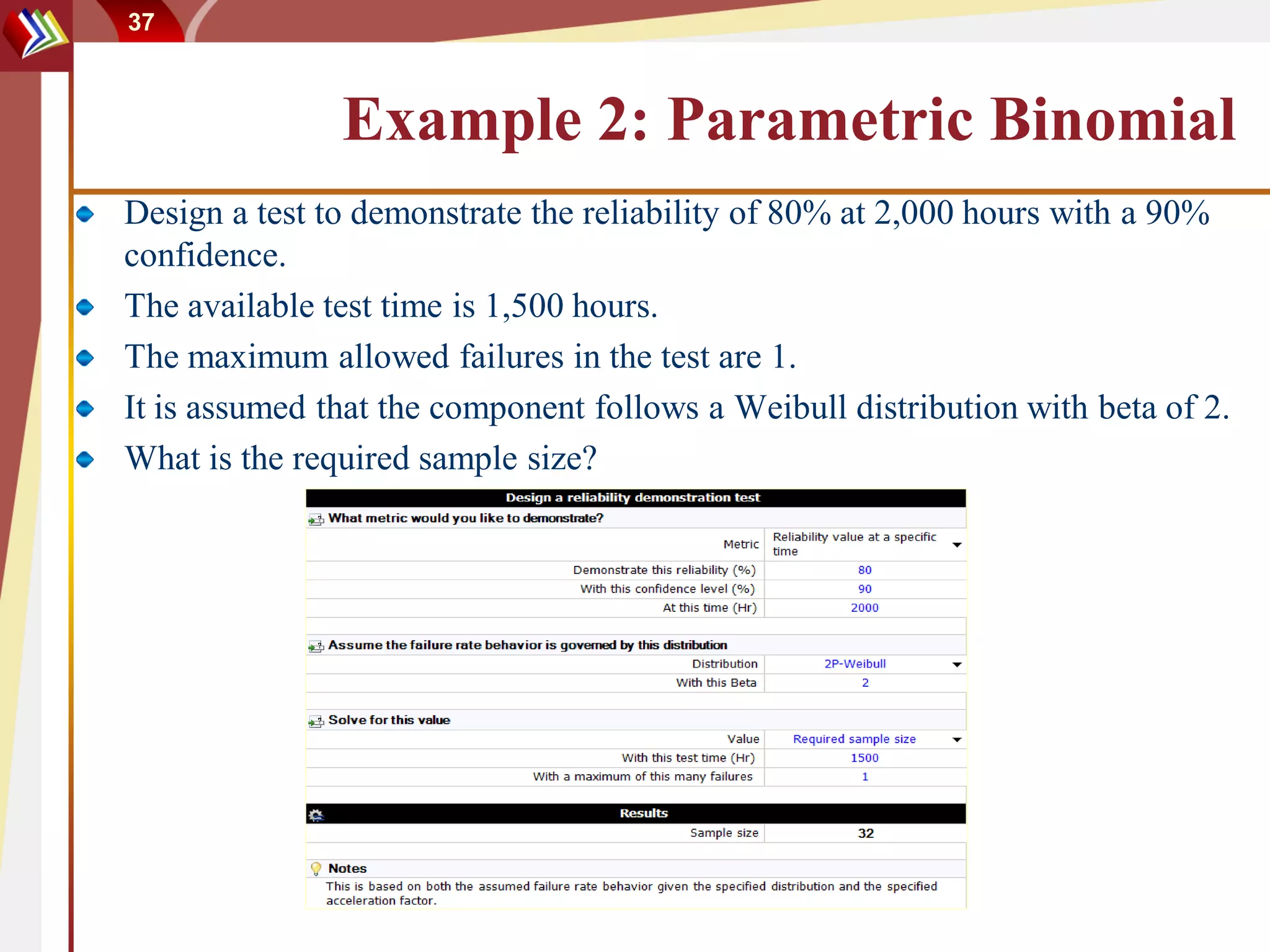

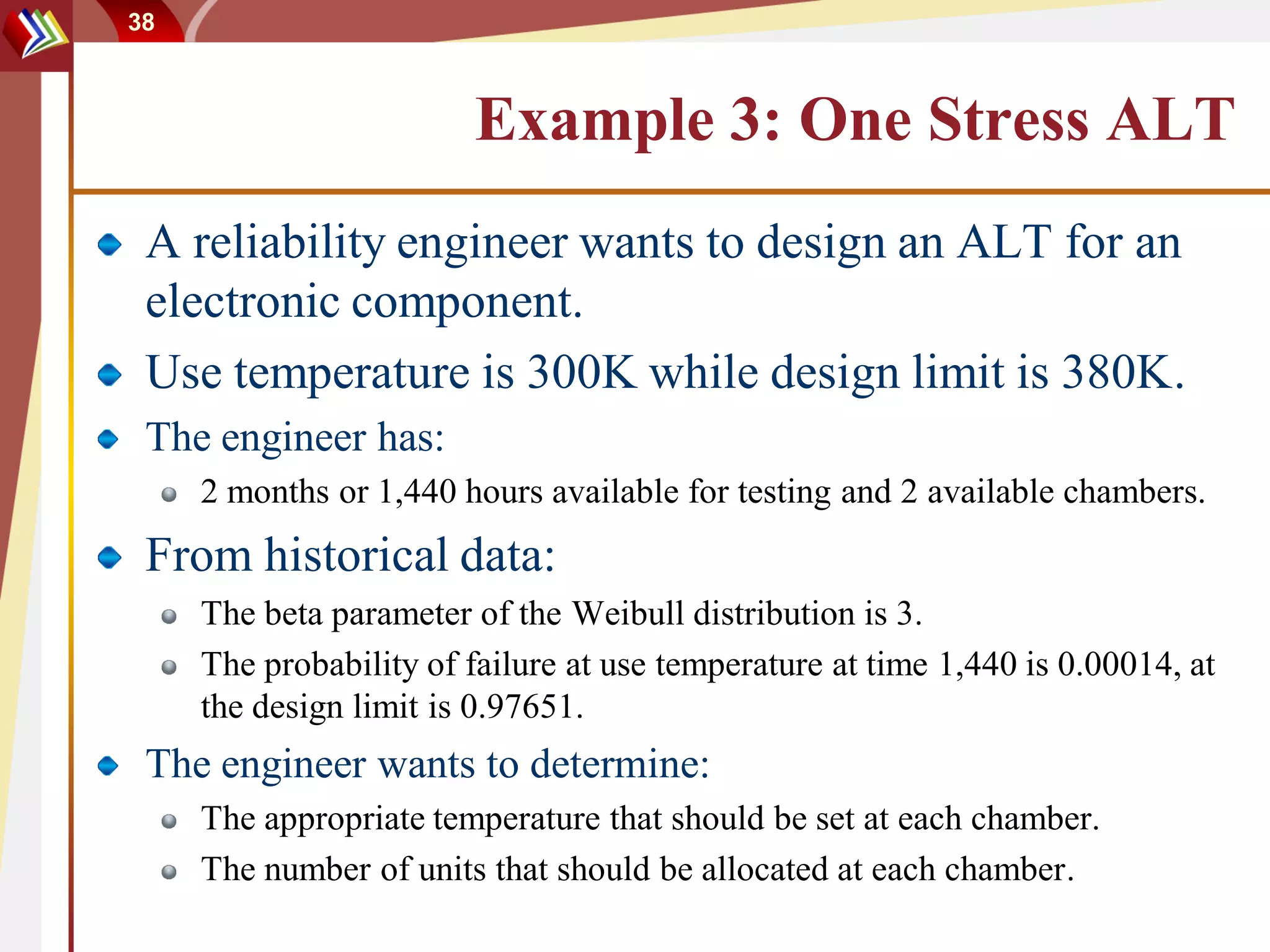

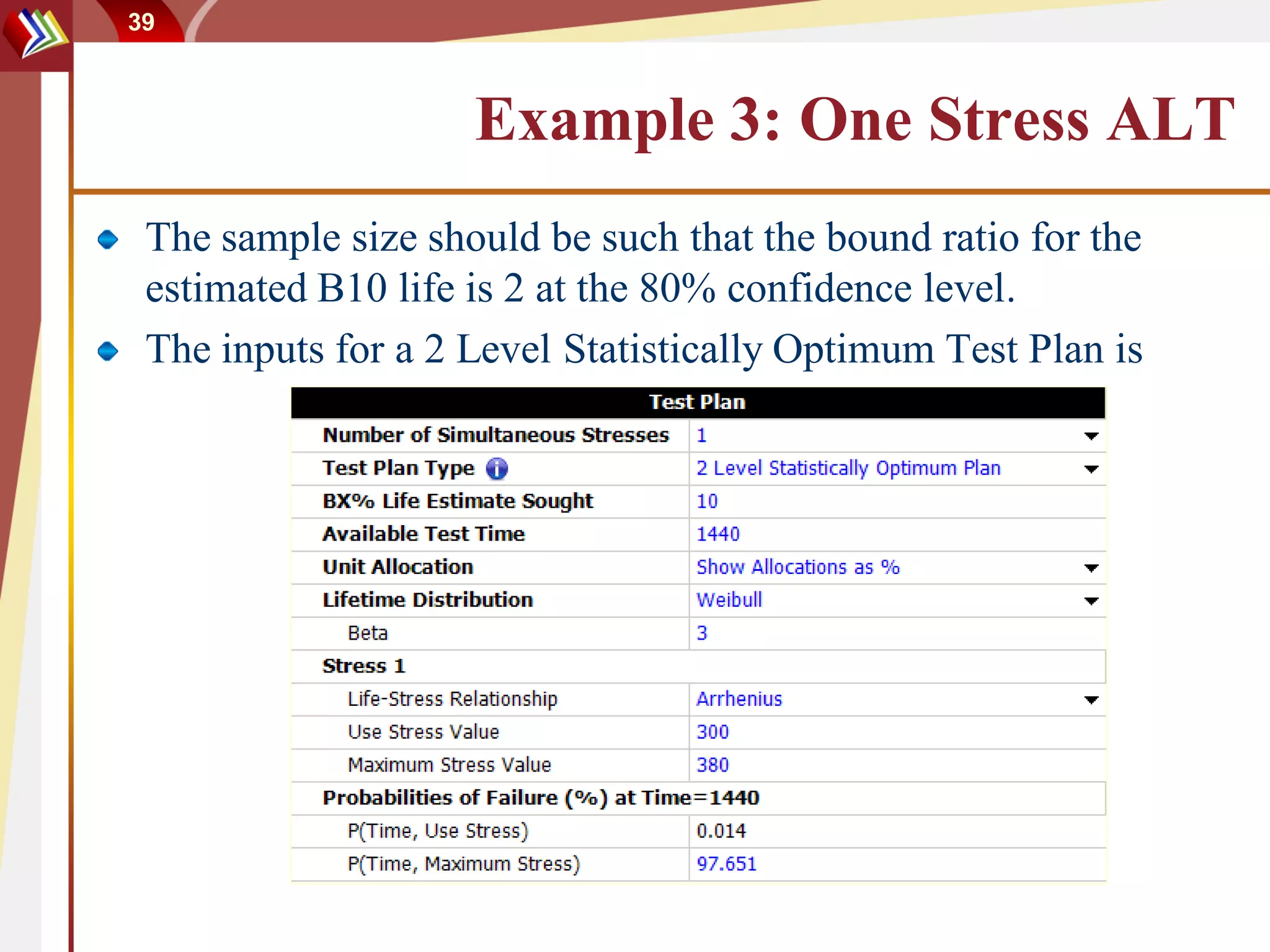

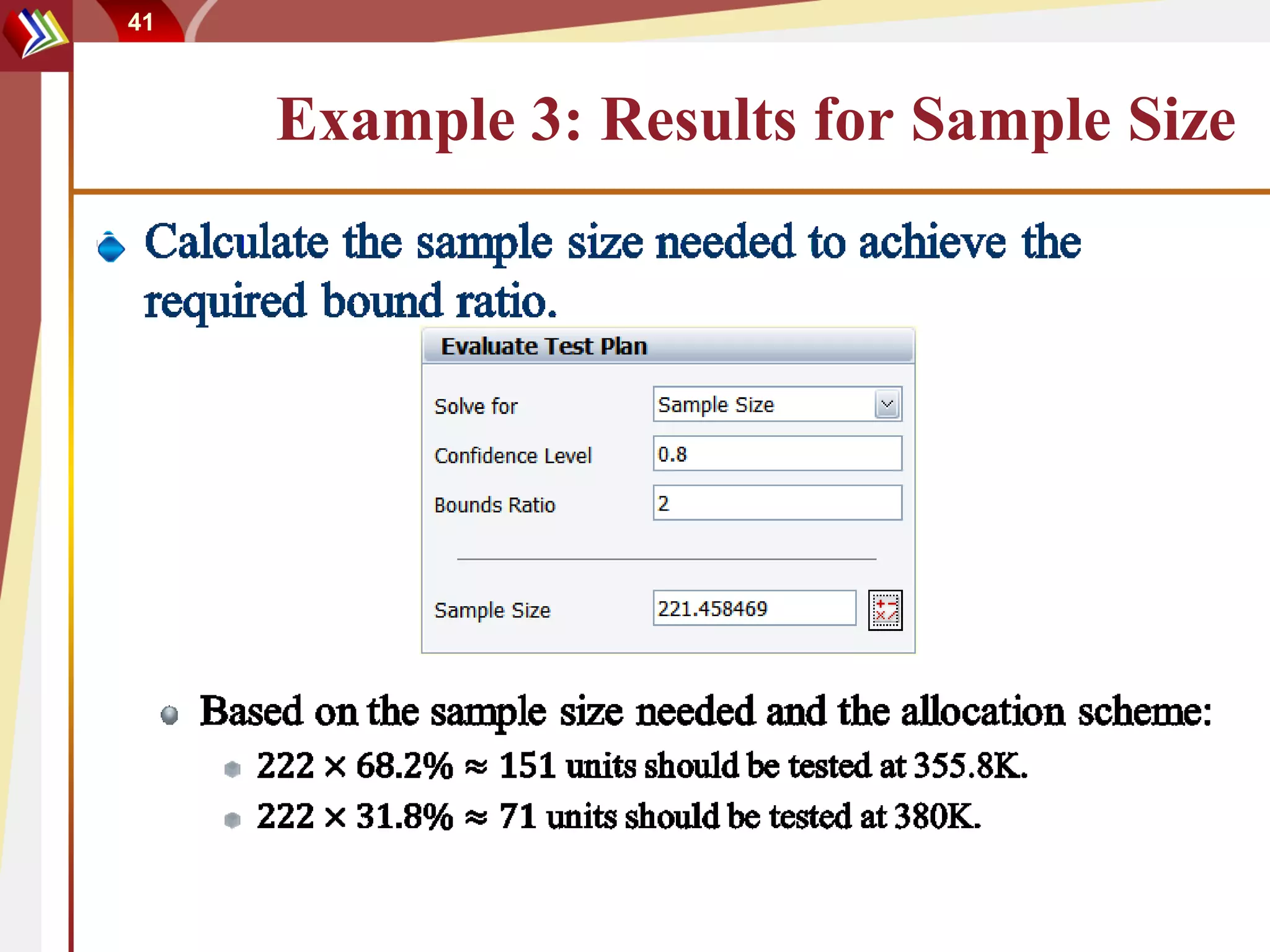

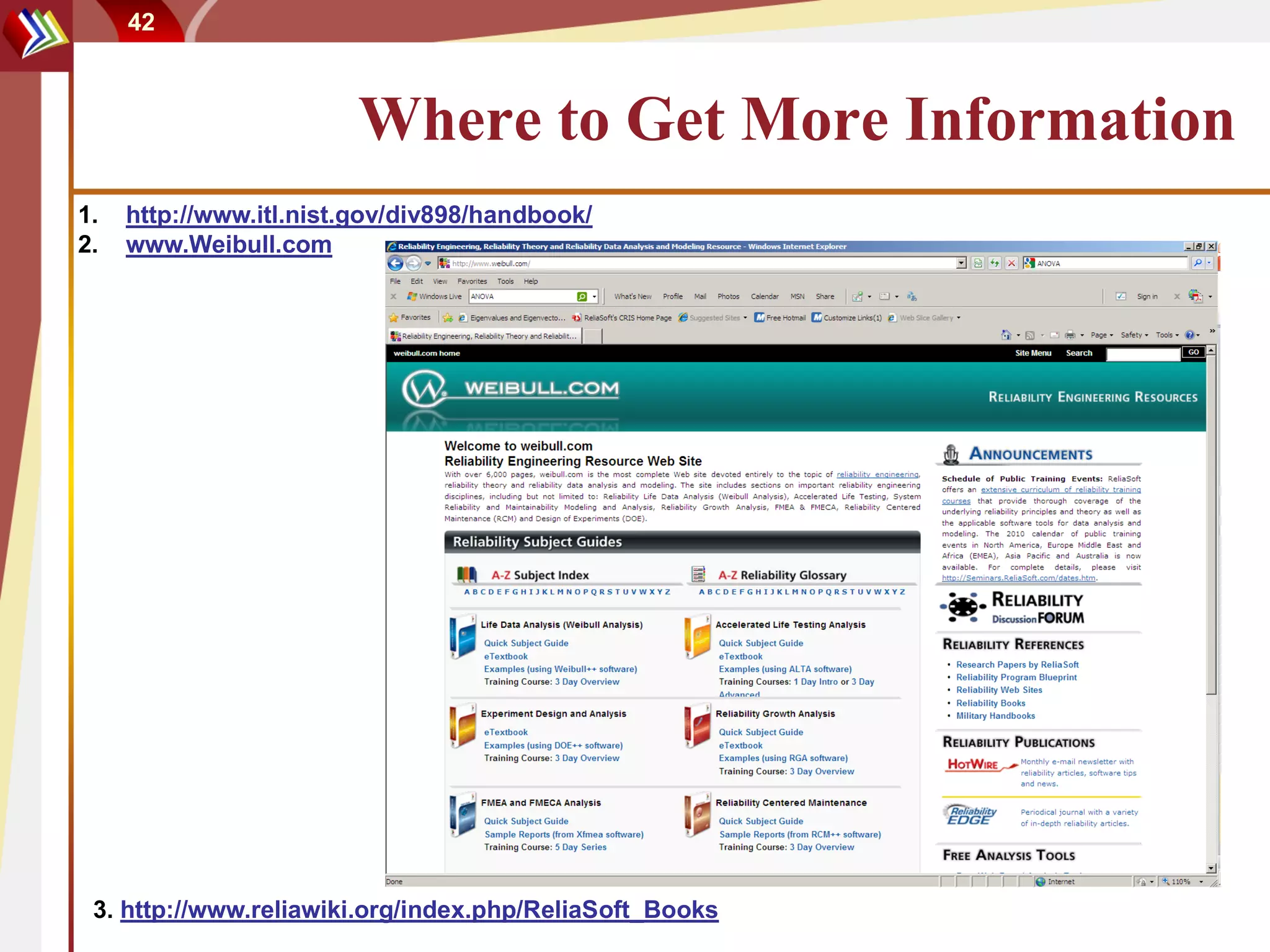

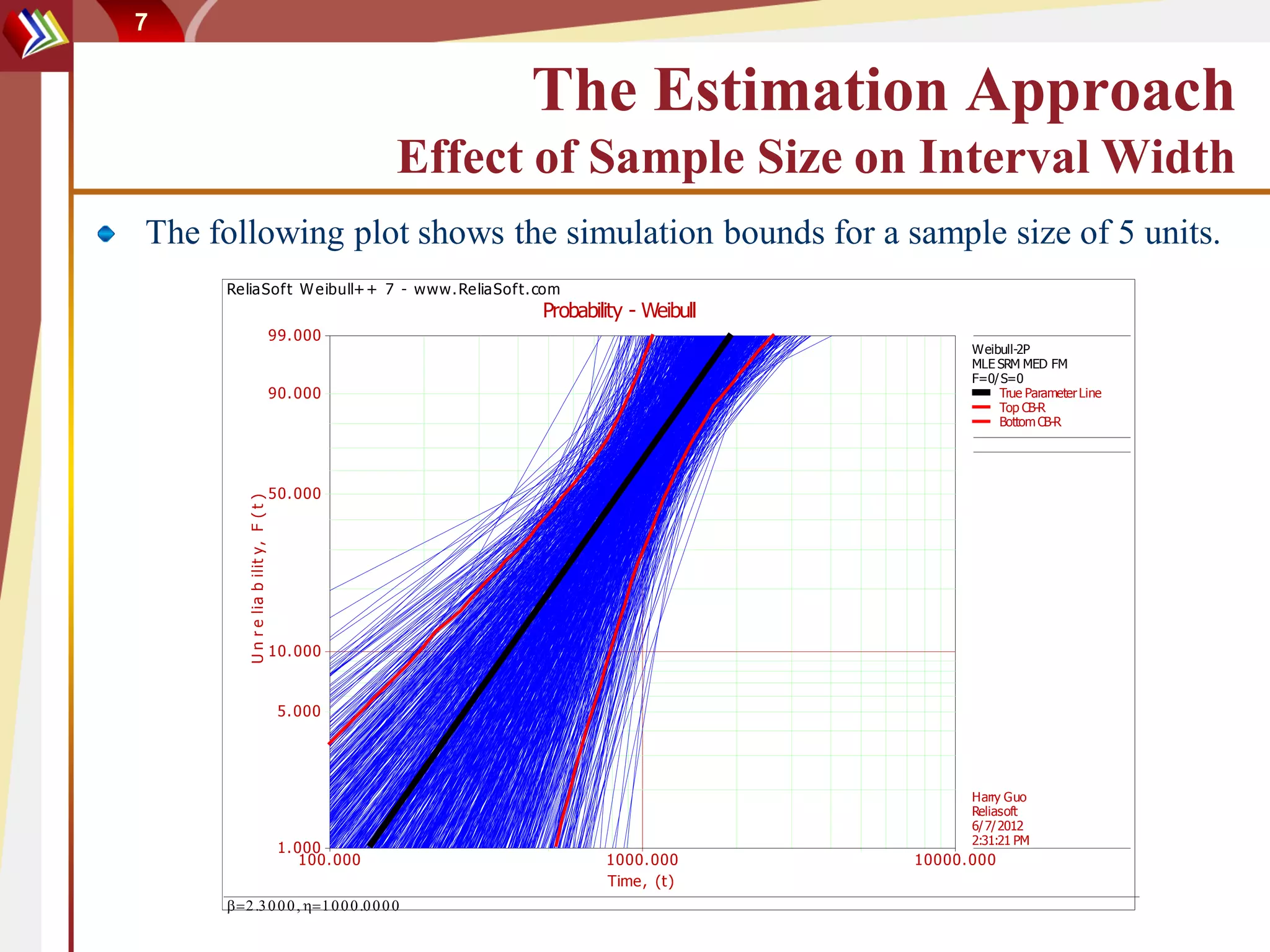

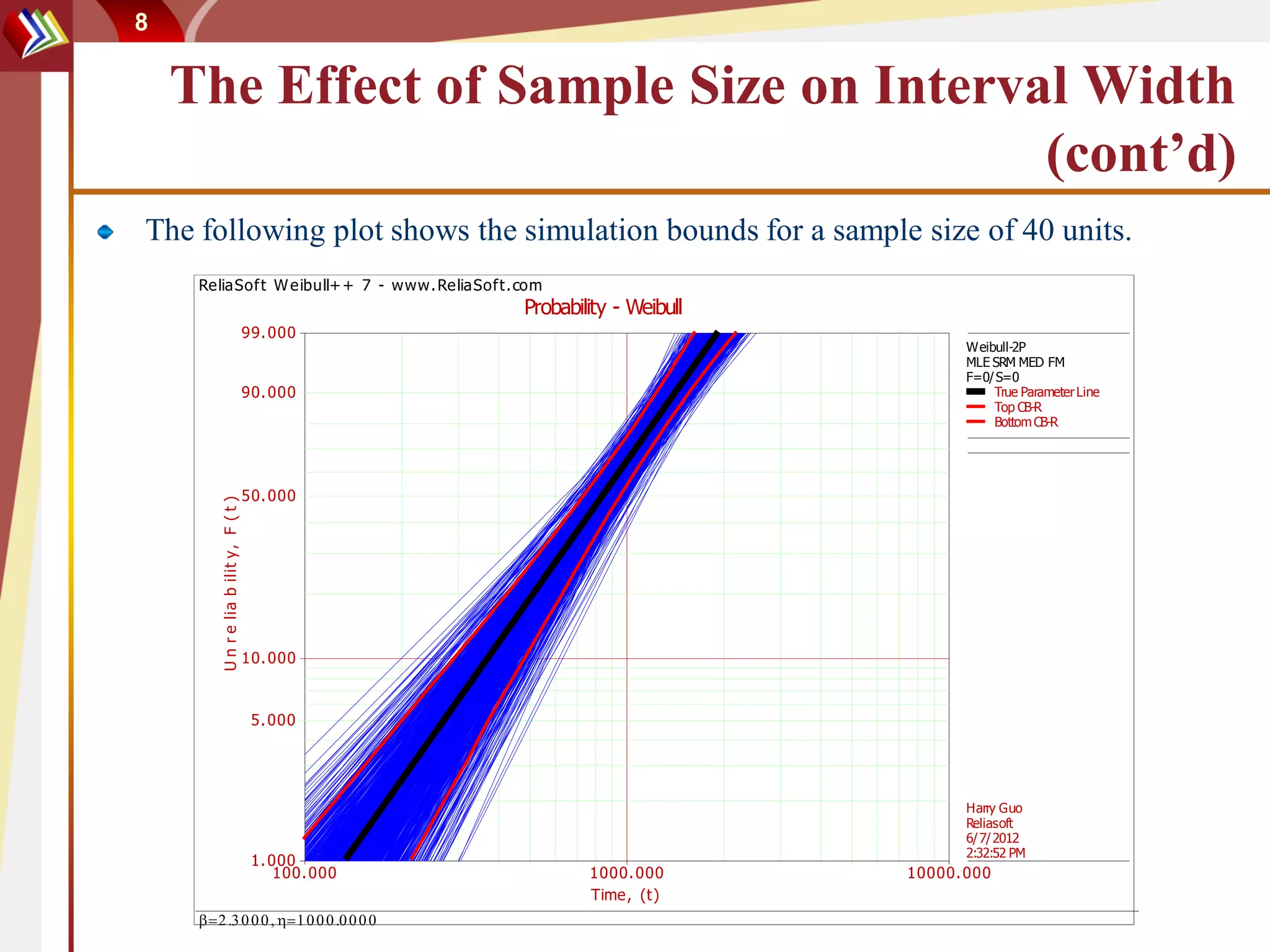

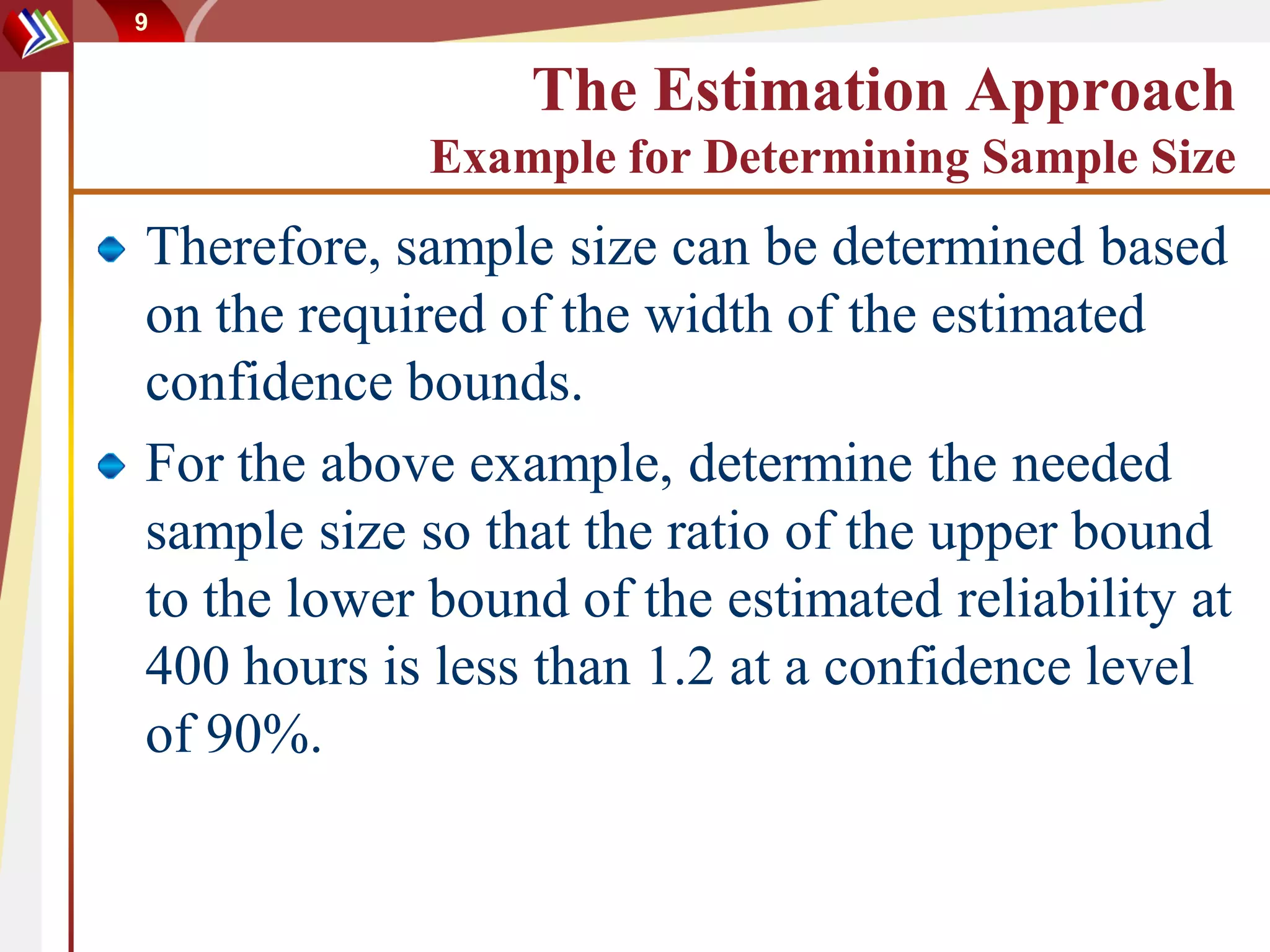

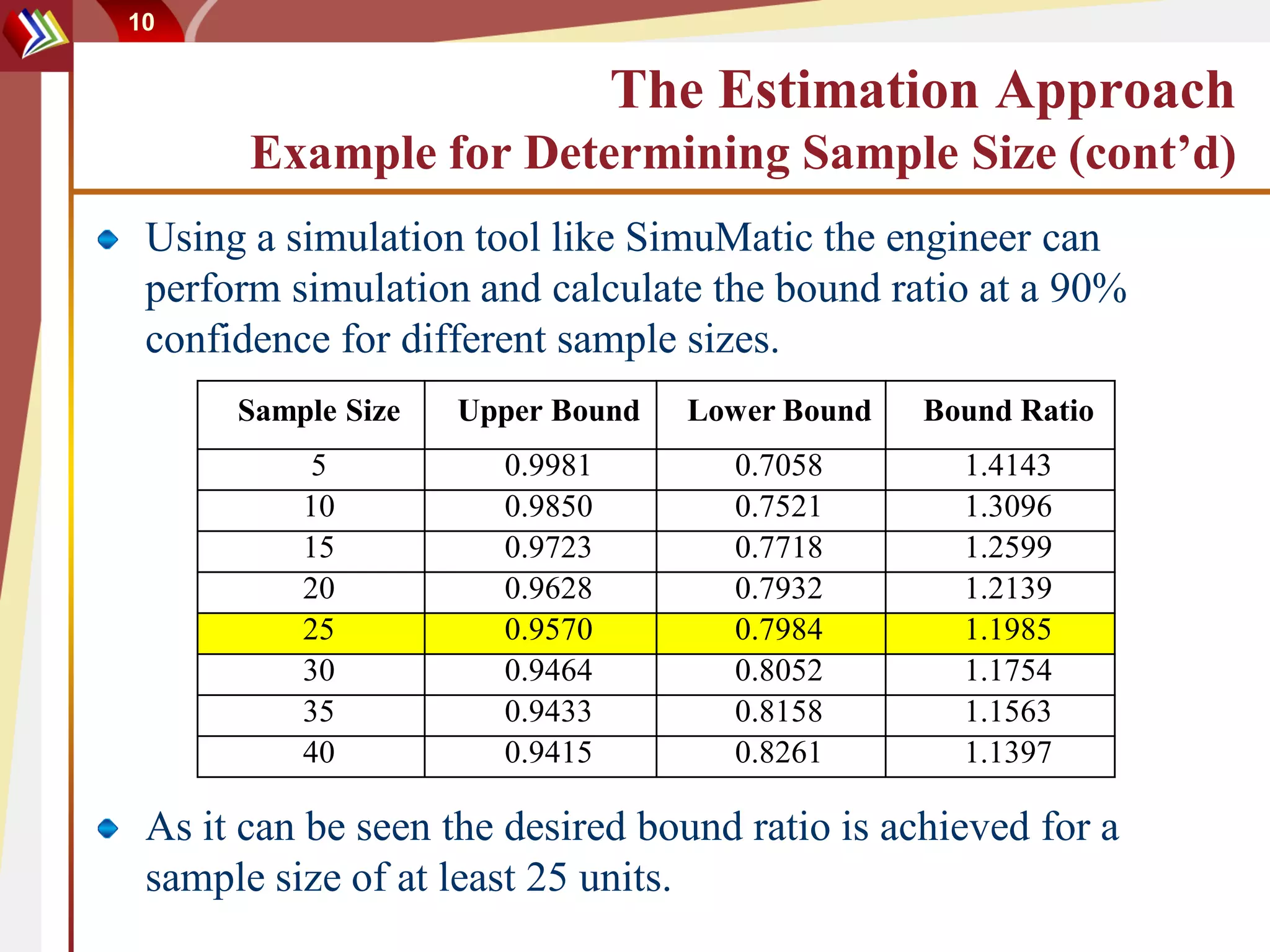

The document discusses methods for determining sample sizes in reliability testing. It covers two main approaches: the estimation approach which aims to control the confidence interval width, and the risk control approach which aims to control type I and type II errors. Examples are provided to demonstrate how to use each approach to determine the needed sample size given parameters like required reliability, confidence level, allowable failures. Both parametric and non-parametric methods are introduced for different test scenarios. Software tools can help calculate the sample sizes required to meet the test objectives.

![15

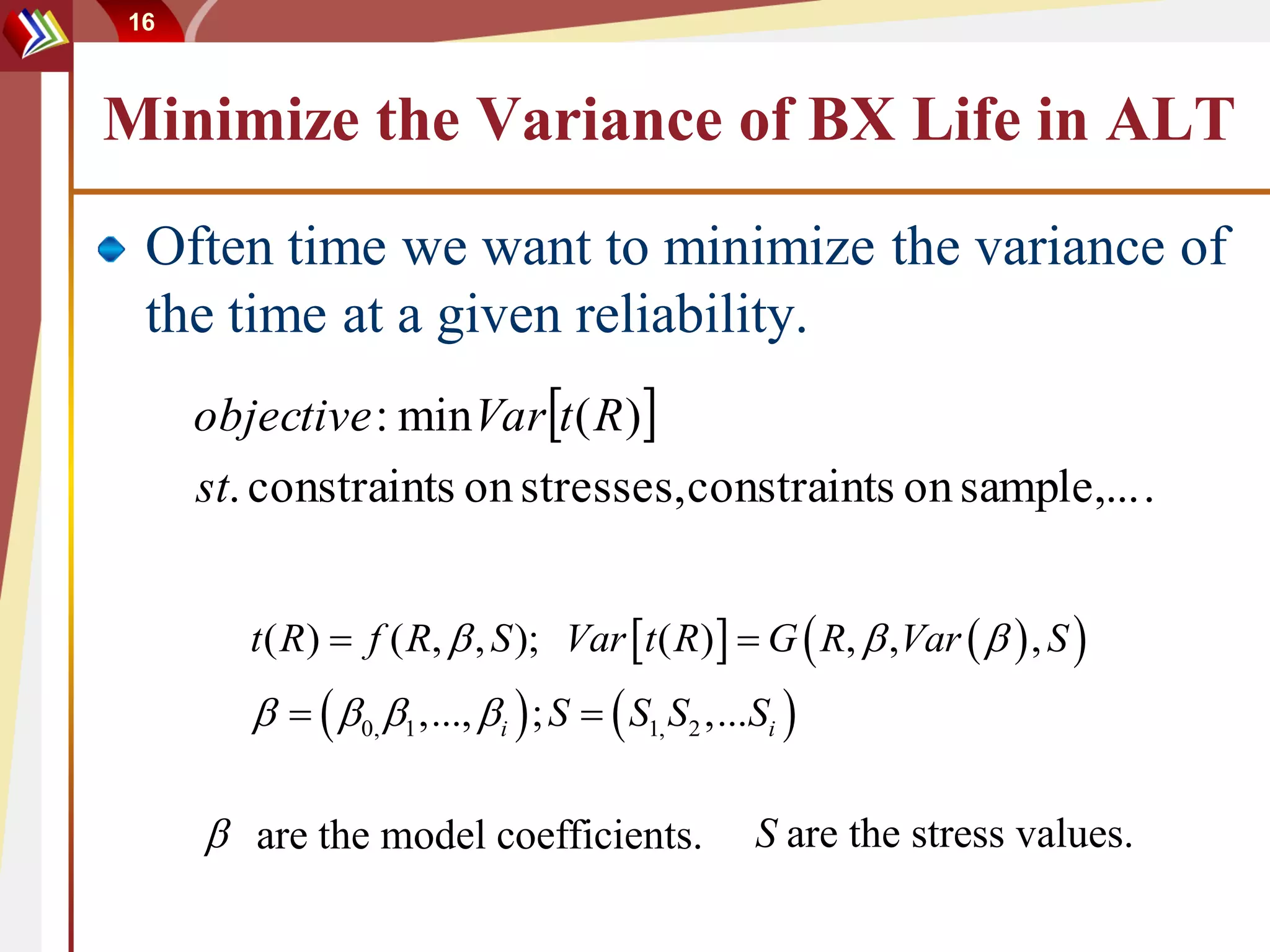

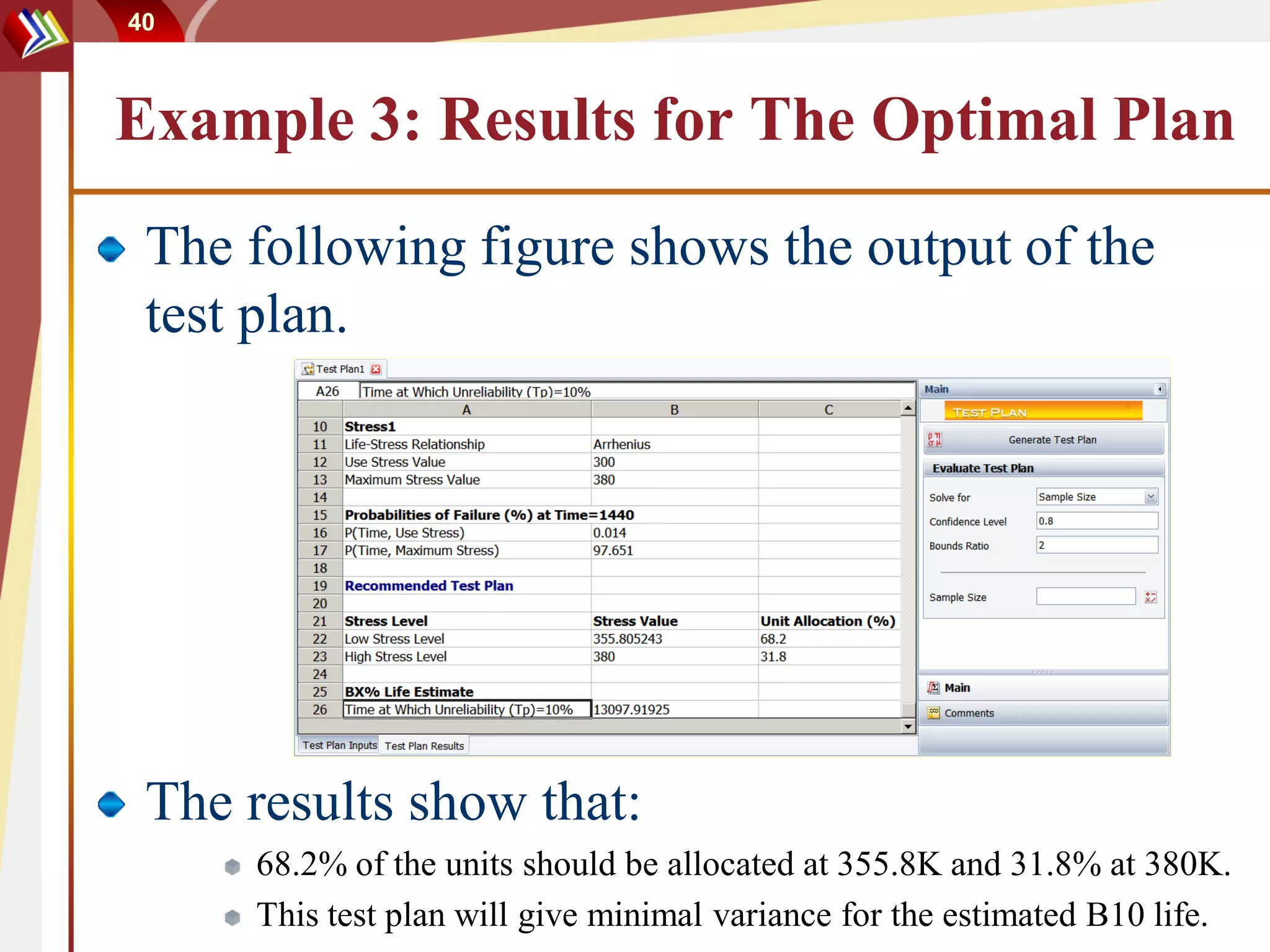

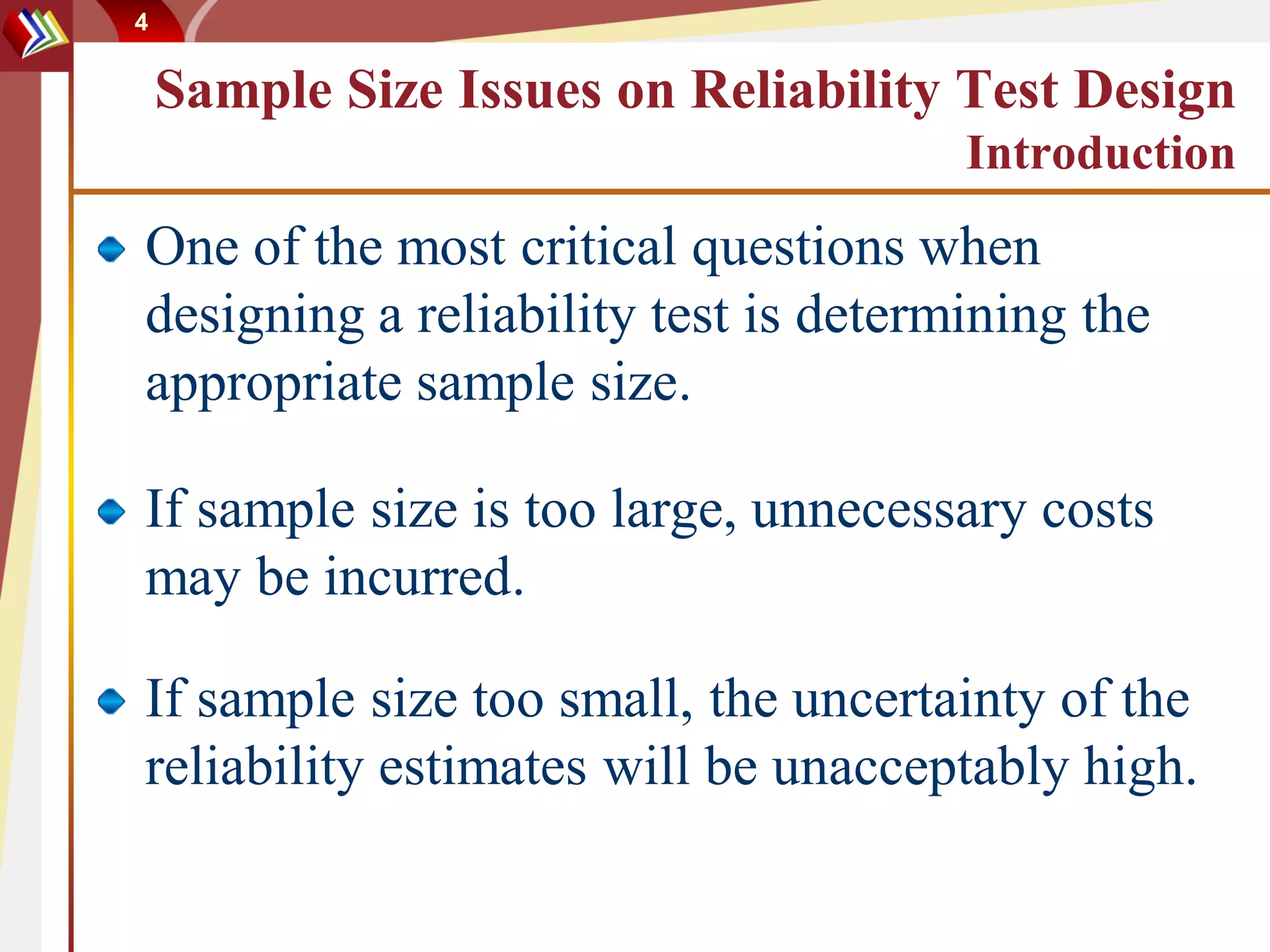

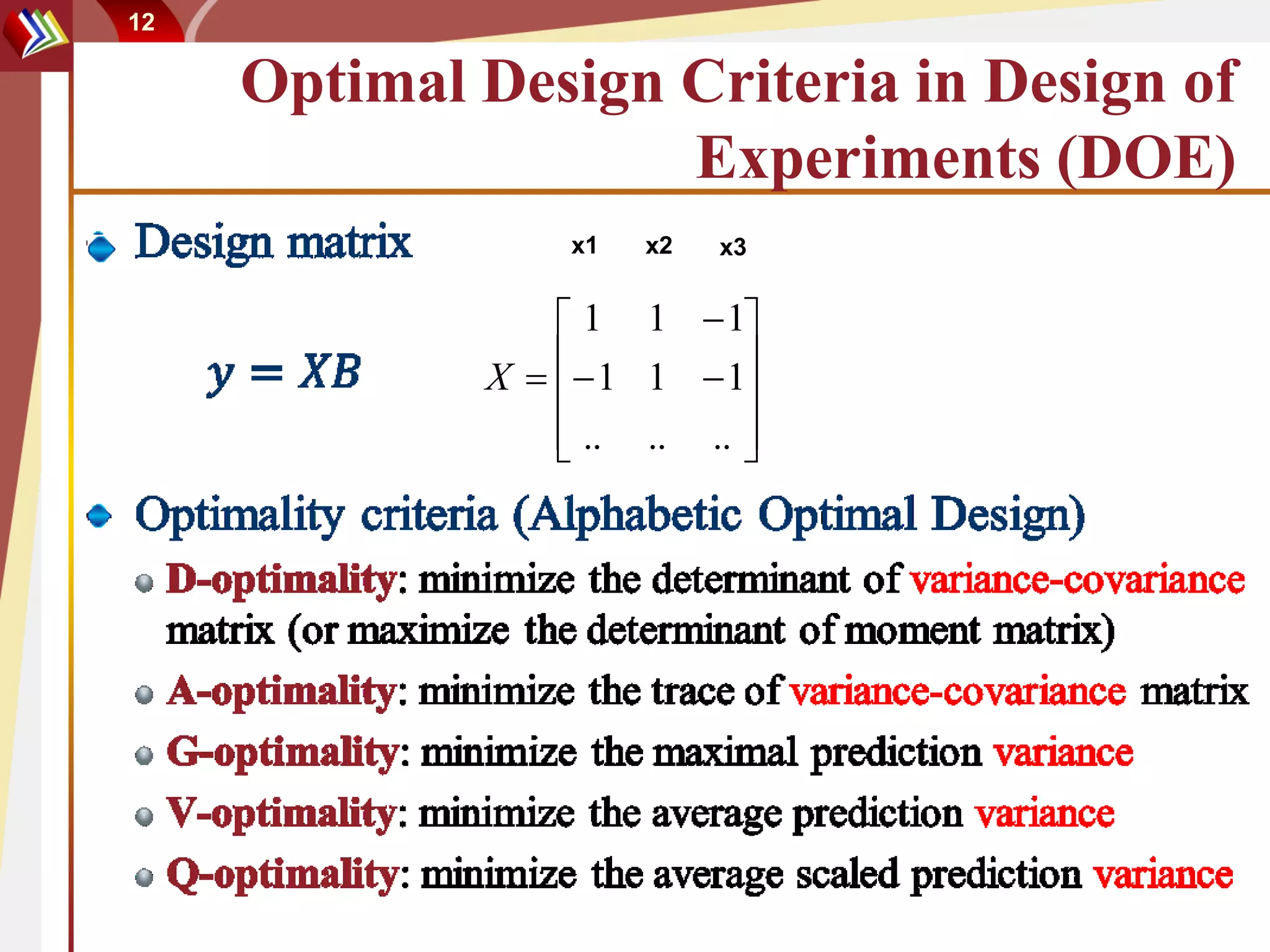

Example: Time-Censored ALT with 2

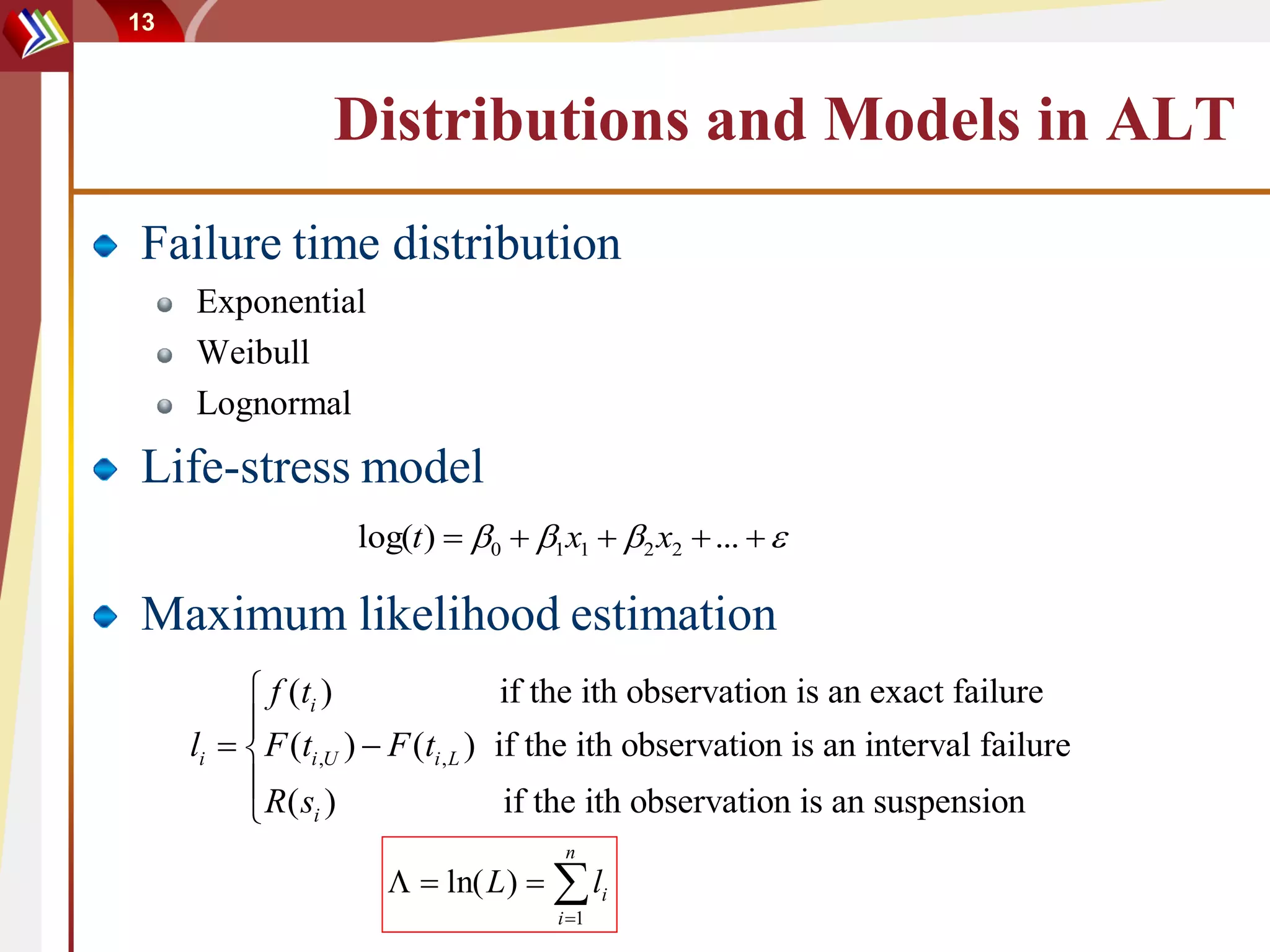

Stresses

Log-likelihood function si

( 0 1 X i ,1 2 X i , 2 12 X i ,1 X i , 2 )

1 zi2, j 1 Yij

li , j ( , ) I ij ln ln 2

(1 I ij ) ln(1 ( si )) if

2 2

I ij

0 if Yij

E[ I ij ] ( si )

Fisher information matrix

n A n x A n x A n x x A

i i i i ,1 i i i ,2 i i i ,1 i ,2 i n A si i i i

n A n x x A n x A

i i i i ,1 i ,2 i i i ,2 i n A s x

i i i i i ,1

F

1 n A n x A i i i i ,1 i n A s x

i i i i i ,2

i

2

n A i i n A s x x

i i i i i ,1 i ,2

Ai i i si

1 i

s

n 2

i

i i si si2 1 i i

1 i

i

Find ni to maximize |F|. Planned distribution

parameter values are needed](https://image.slidesharecdn.com/samplesizeissuesonreliabilitytestdesign15sep2012rev1-120912041448-phpapp02/75/Sample-size-issues-on-reliability-test-design-17-2048.jpg)