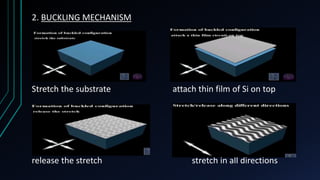

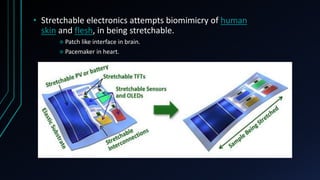

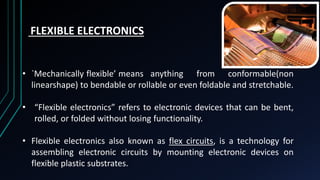

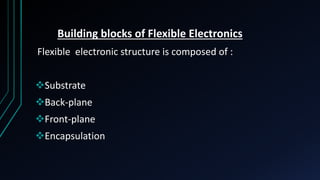

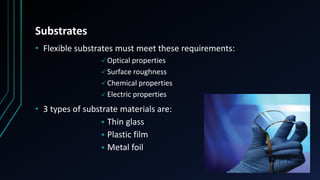

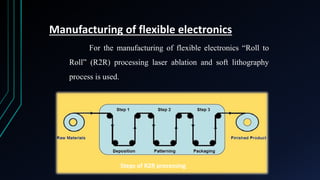

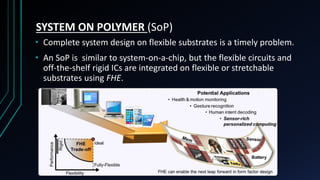

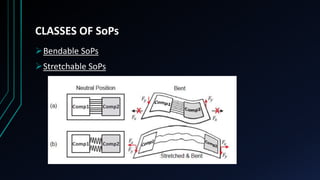

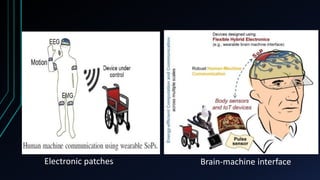

Flexible and stretchable electronics can conform to non-linear shapes and enable new form factors for computing devices. Stretchable electronics uses elastic substrates and manufacturing techniques like silicon islands or buckling mechanisms to allow stretching. Flexible electronics mounts electronic devices on flexible plastic substrates and uses roll-to-roll processing. Flexible hybrid electronics combines flexible and rigid components on flexible substrates to overcome performance limitations of purely flexible electronics. Potential applications include electronic patches and brain-machine interfaces.

![FLEXIBLE HYBRID ELECTRONICS [FHE]

• The architecture that combine flexible elements and rigid silicon to

overcome the performance limitations of purely flexible electronics.

• FHE refers to physically flexible systems that integrate commercial off-

the-shelf rigid integrated circuits (ICs) on flexible or stretchable

substrates.

• FHE can “deliver the functionality of current state-of-the-art mobile

platforms in a truly pervasive form factor.”](https://image.slidesharecdn.com/flexibleandstretchableelectronics-171008071648/85/Flexible-and-stretchable-electronics-17-320.jpg)

![Bibliography

[1] American Semiconductor Inc. FleX

TM

Silicon-on-Polymer

http://www.americansemi.com.

[2] A. Ahmadi, O. Dehzangi, and R. Jafari, “Brain-Computer Interface

Signal Processing Algorithms: A Computational Cost Vs. Accuracy

Analysis For Wearable Computers,” in In Proc. of Intl. Conf. on

Wearable and Implantable Body Sensor Networks, 2012, pp. 40–45.

[3] American Semiconductor Inc. FleX-MCU

TM

. http://www.americansemi.com, last accessed May 2016.

[4] P. Bonato, “Wearable Sensors/Systems And Their Impact On Biomedical

Engineering,” IEEE Engineering in Medicine and Biology Magazine,

vol. 22, no. 3, pp. 18–20, 2003.](https://image.slidesharecdn.com/flexibleandstretchableelectronics-171008071648/85/Flexible-and-stretchable-electronics-29-320.jpg)