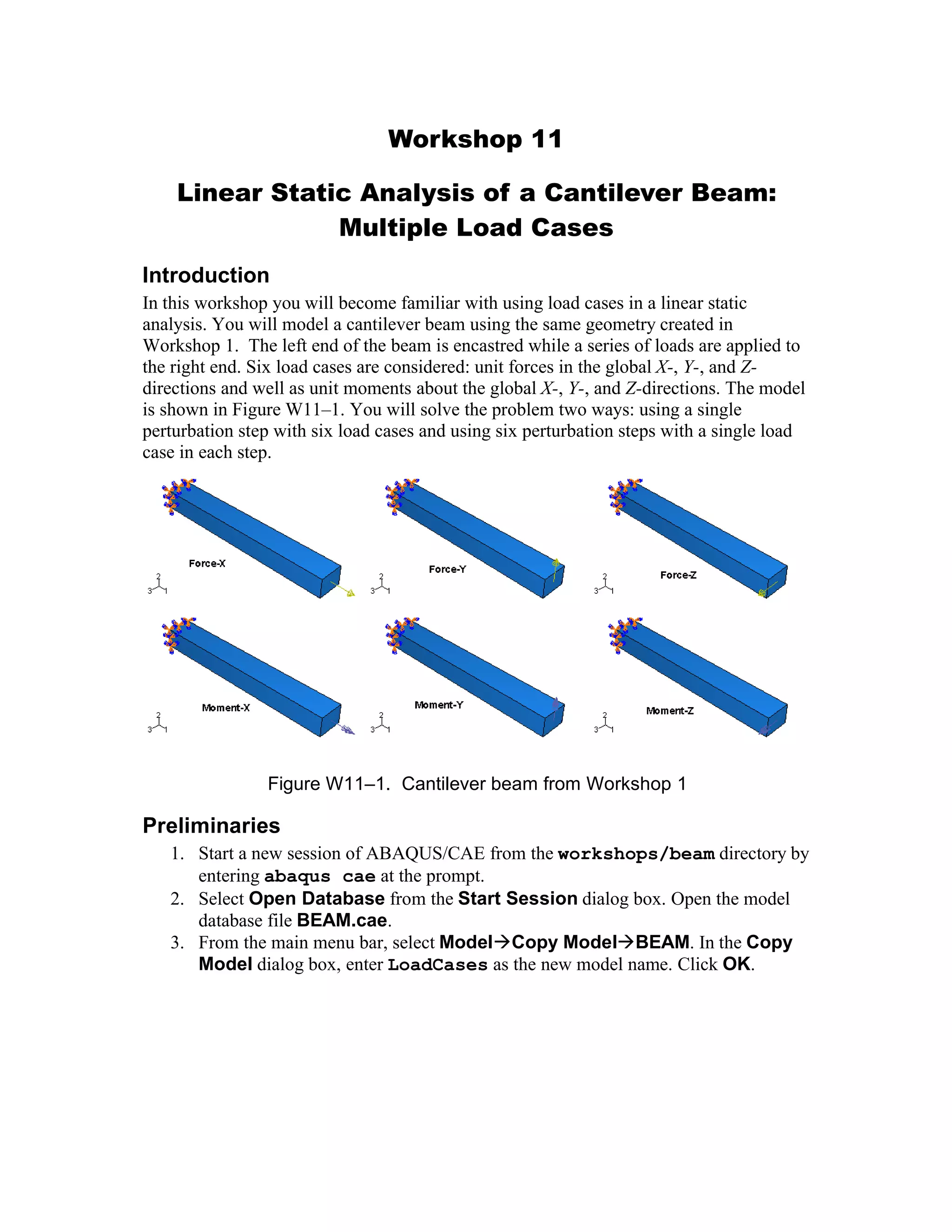

This document describes modeling a cantilever beam with multiple load cases using ABAQUS. The beam is subjected to unit forces and moments applied at its free end. These loads are modeled using either a single analysis with six load cases, or six separate analyses with one load case each. The results are identical but the multiple load case approach is faster.