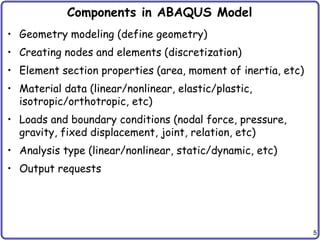

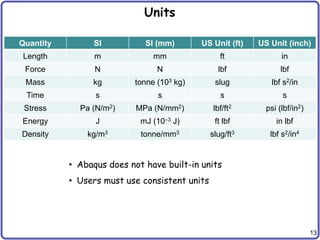

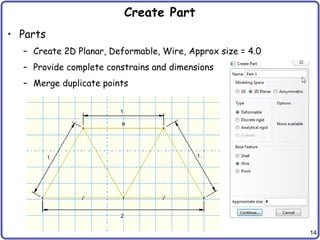

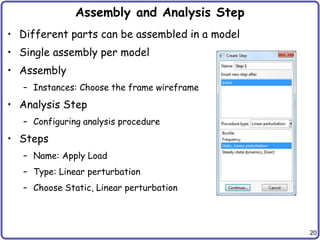

This document provides an overview of finite element analysis using Abaqus. It discusses the basics of Abaqus including preprocessing with Abaqus/CAE, solving models with Abaqus/Standard, and postprocessing output files. It also describes the various components and steps involved in building an Abaqus model including geometry creation, material properties, meshing, boundary conditions, loads, and running an analysis job. An example is presented demonstrating how to model an overhead hoist frame.