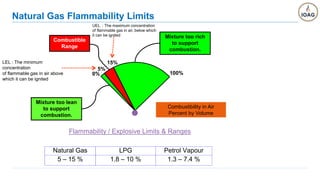

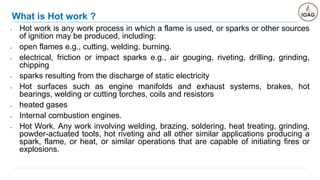

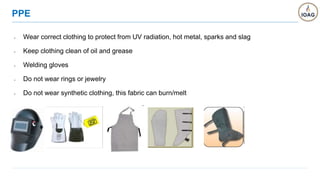

This document provides information on various hot work activities and safety precautions. It discusses natural gas, welding, gas cutting, grinding, commissioning, and hot tapping. For each topic, it defines key terms, describes the process, and lists associated hazards and control measures. The key points are: natural gas is flammable and odorless, welding involves heating metals to join them, gas cutting uses fuel gases and oxygen to cut metals, grinding uses abrasive wheels to remove material, and hot tapping connects to pressurized pipes and vessels without shutting them down. Safety precautions include permits, inspections, PPE, ventilation, fire watches, and eliminating ignition sources and combustibles from work areas.