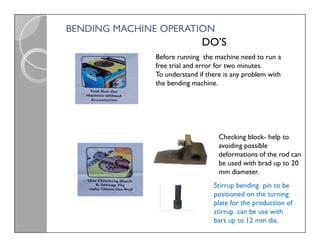

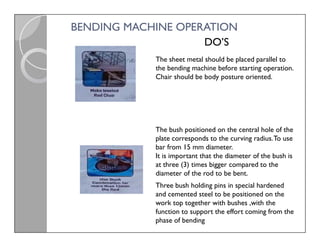

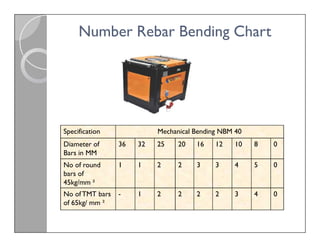

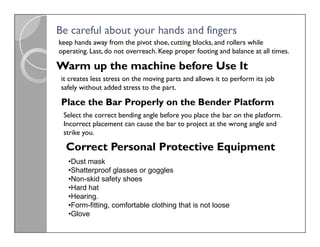

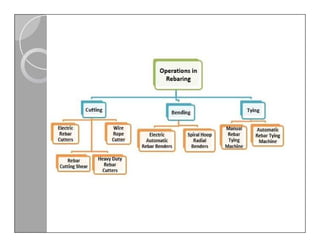

Bar bending machines consist of an electric motor, gearbox, and extended shaft to bend rebar. There are different types including portable, electric, hydraulic, and automatic benders. Proper operation of bending machines requires training operators, inspecting the machine, keeping the work area clean, and using safety equipment. Operators should not exceed the machine's capacity, operate without safety guards, or place body parts near moving parts to avoid injury. Following manufacturers' safety instructions and wearing protective equipment can help safely operate bar bending machines.