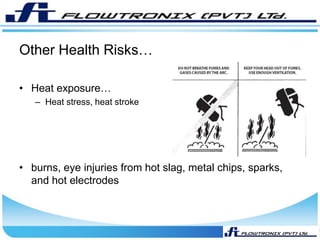

This document outlines various health and safety hazards associated with welding. It discusses hazards from gases and fumes, including exposure to heavy metals like chromium and nickel. Short term exposure can cause metal fume fever, while long term exposure increases cancer risks. Other risks include heat exposure, burns, electrical shock, fires or explosions from sparks near flammables, trips and falls, and hazards in confined spaces like low oxygen. The document recommends using proper ventilation, protective equipment like respirators, gloves, and clothing, and locking out energy sources to prevent electrical and other hazards.