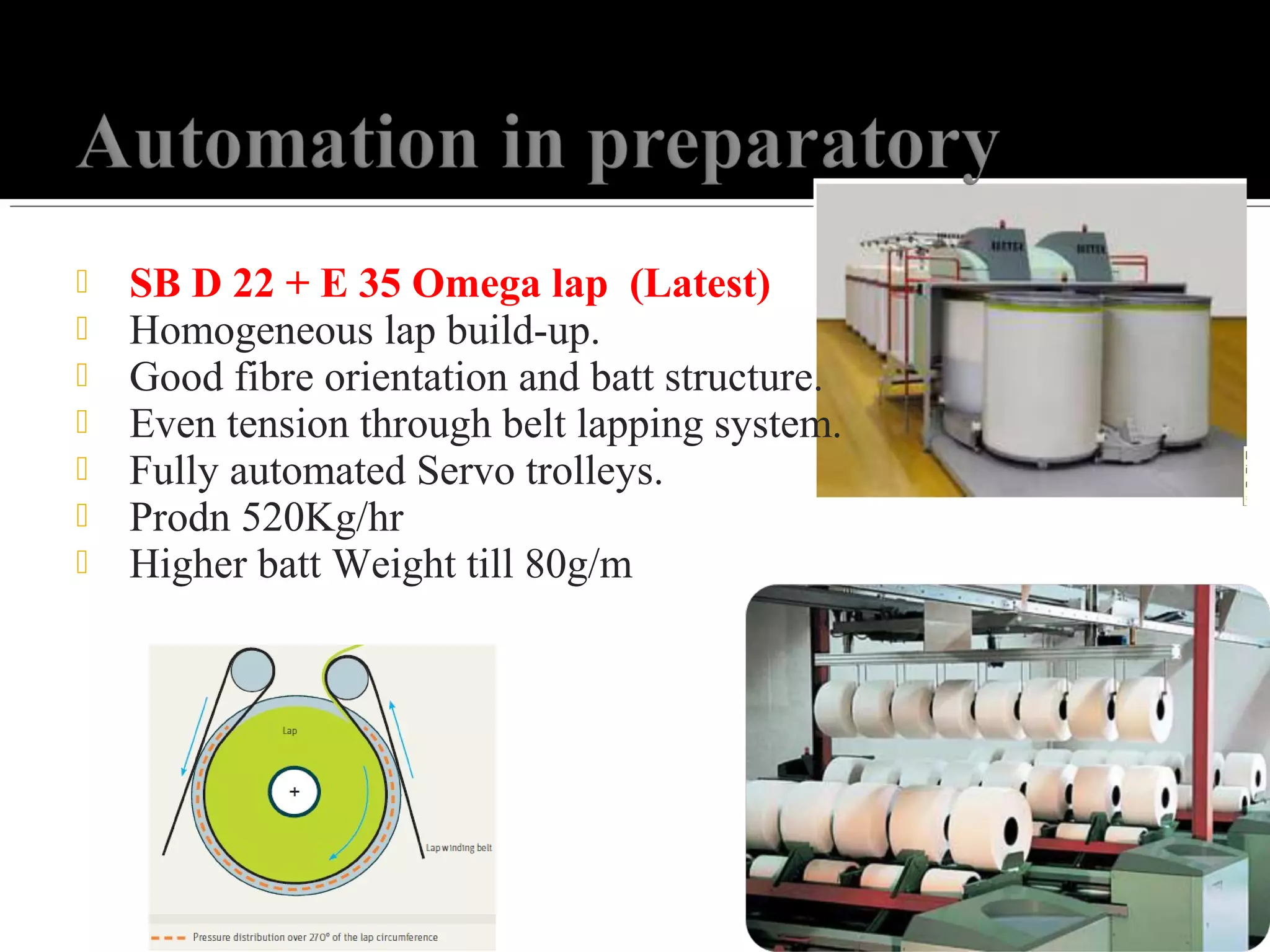

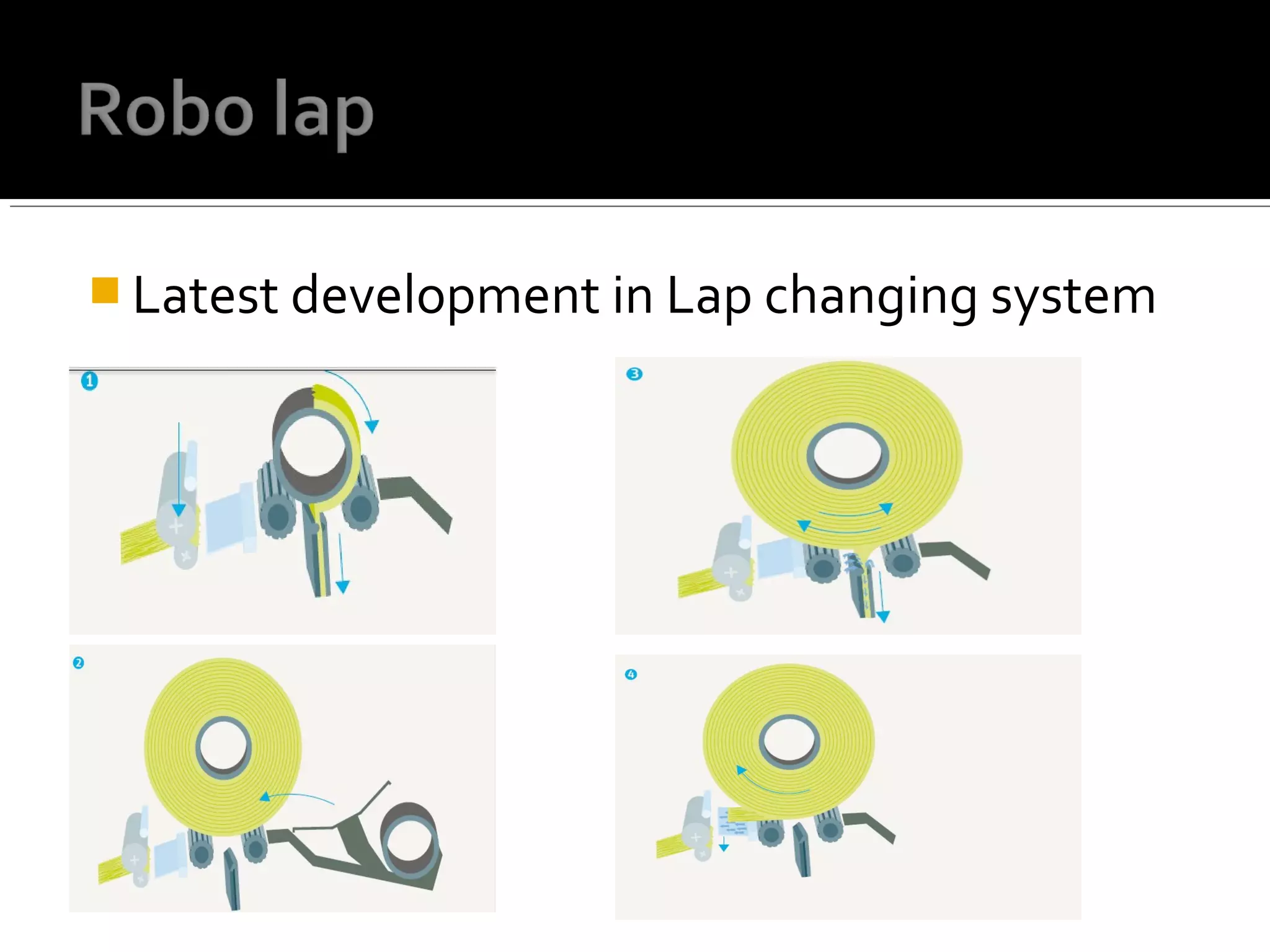

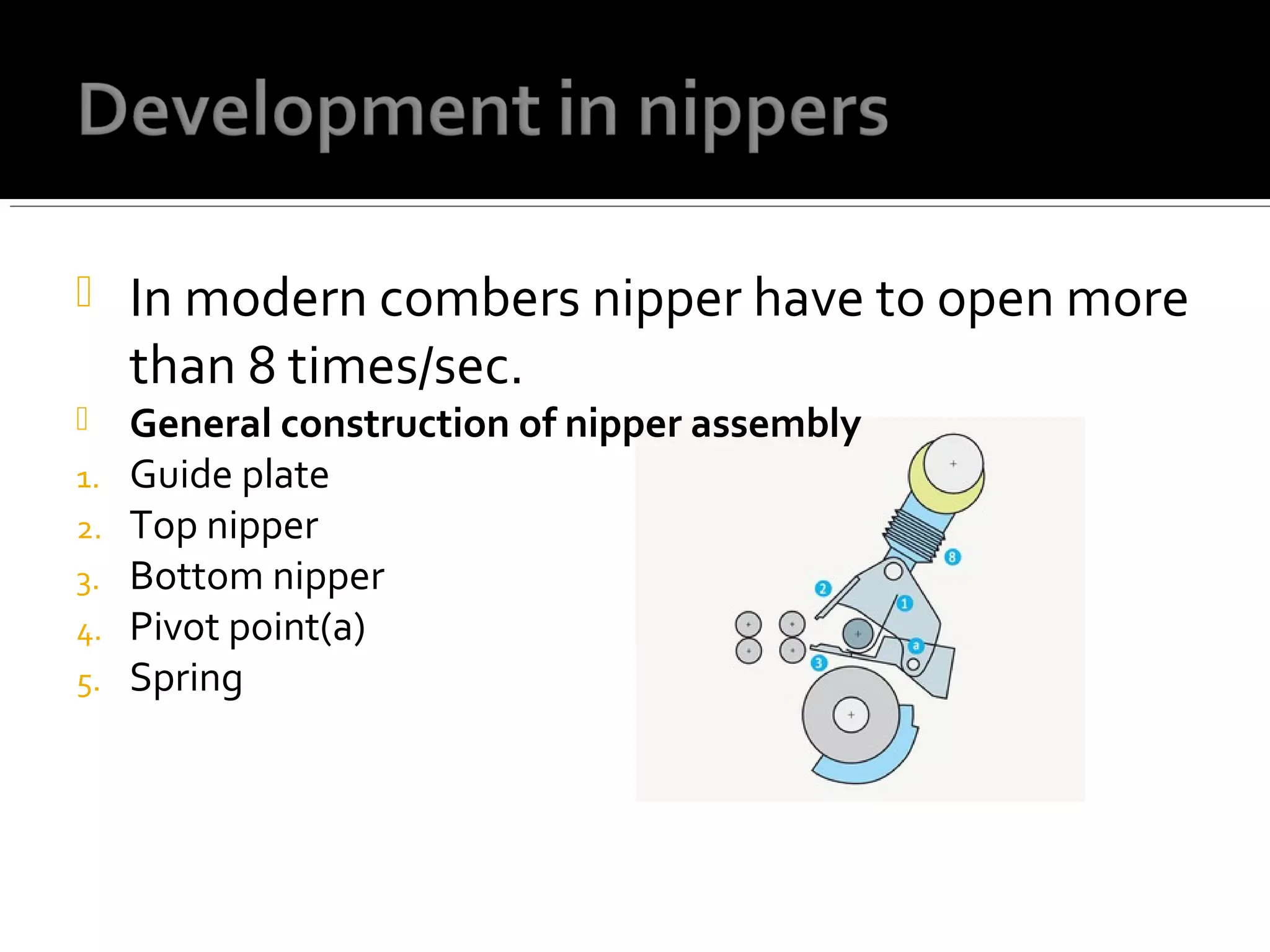

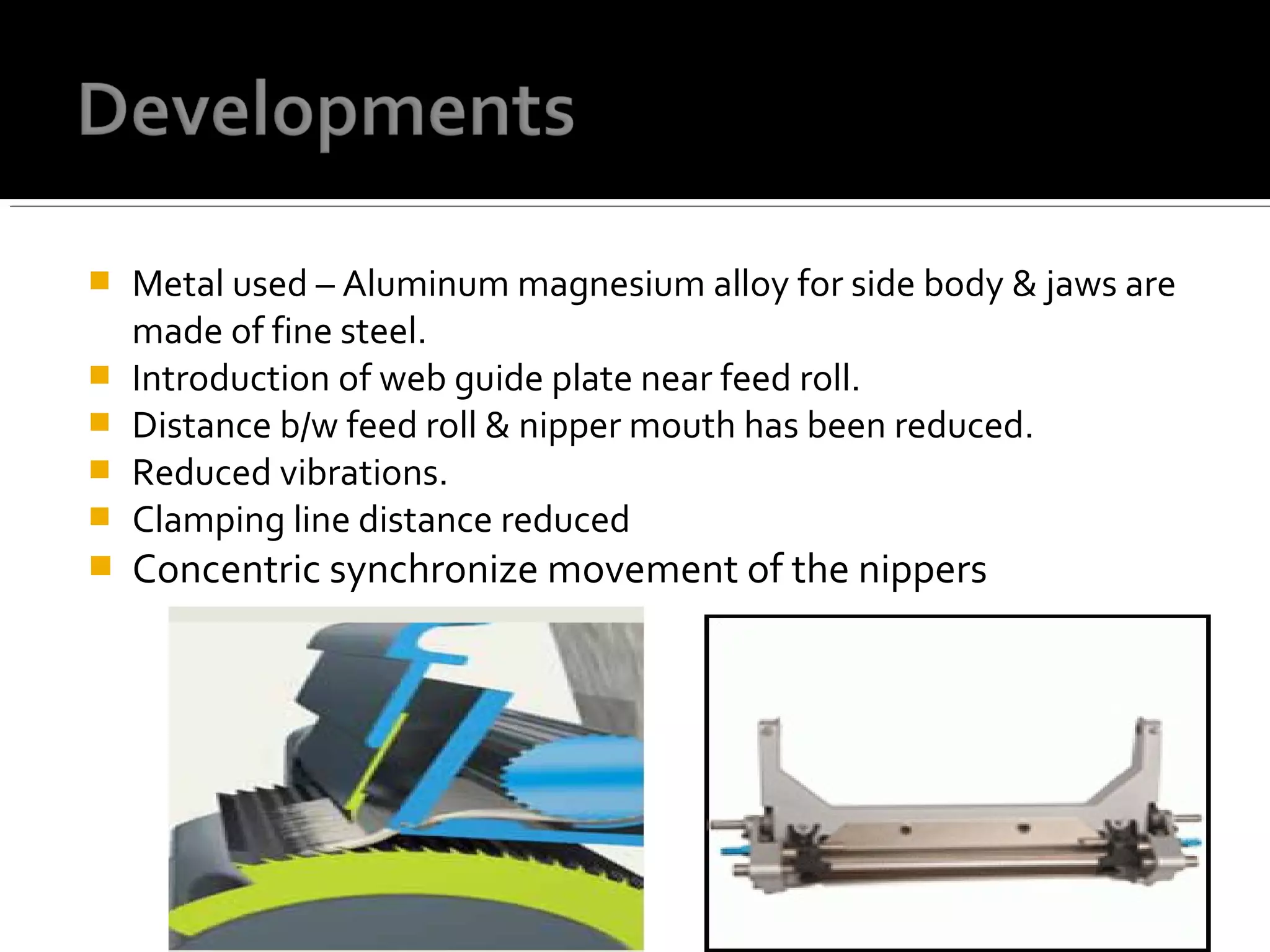

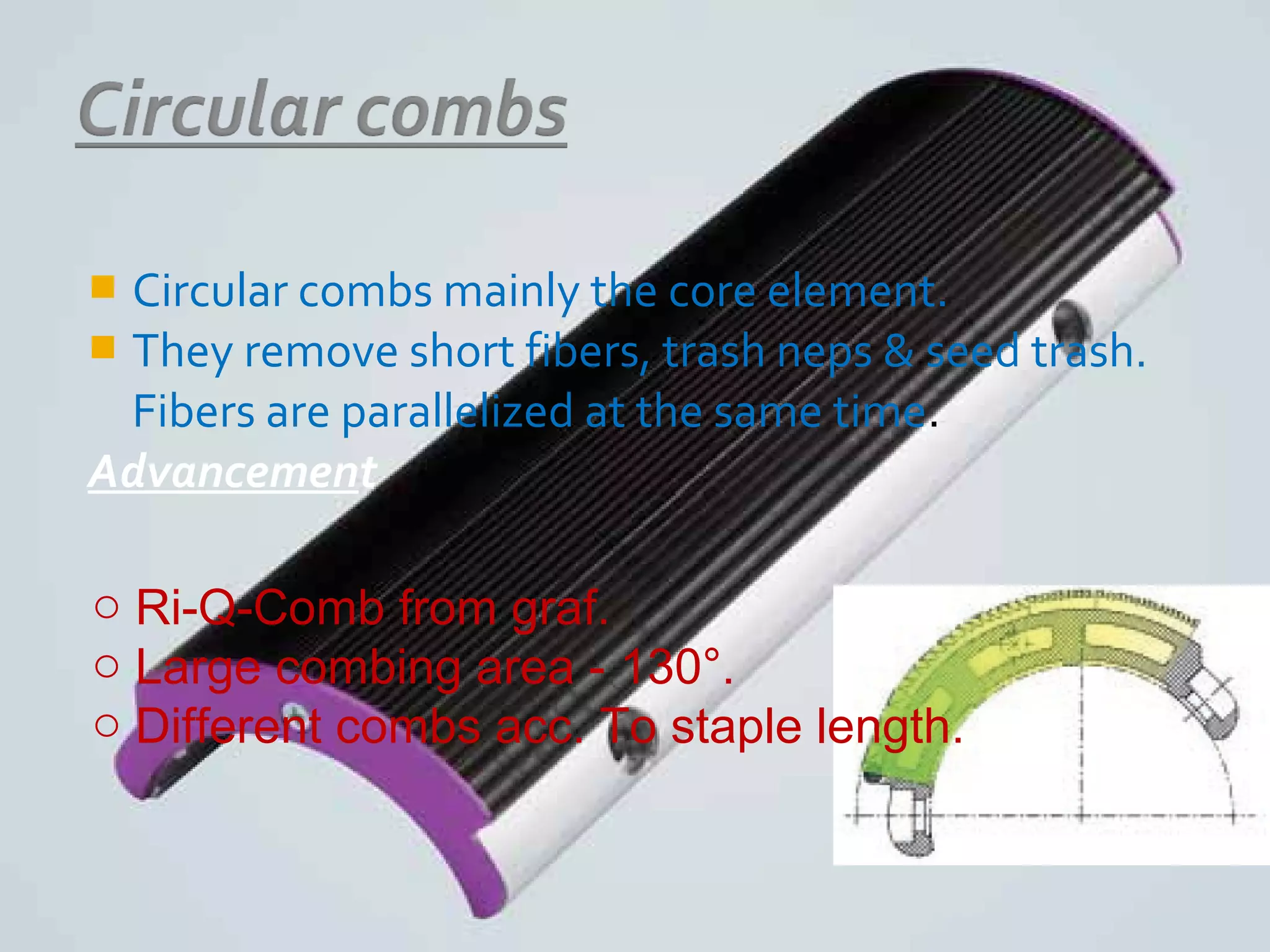

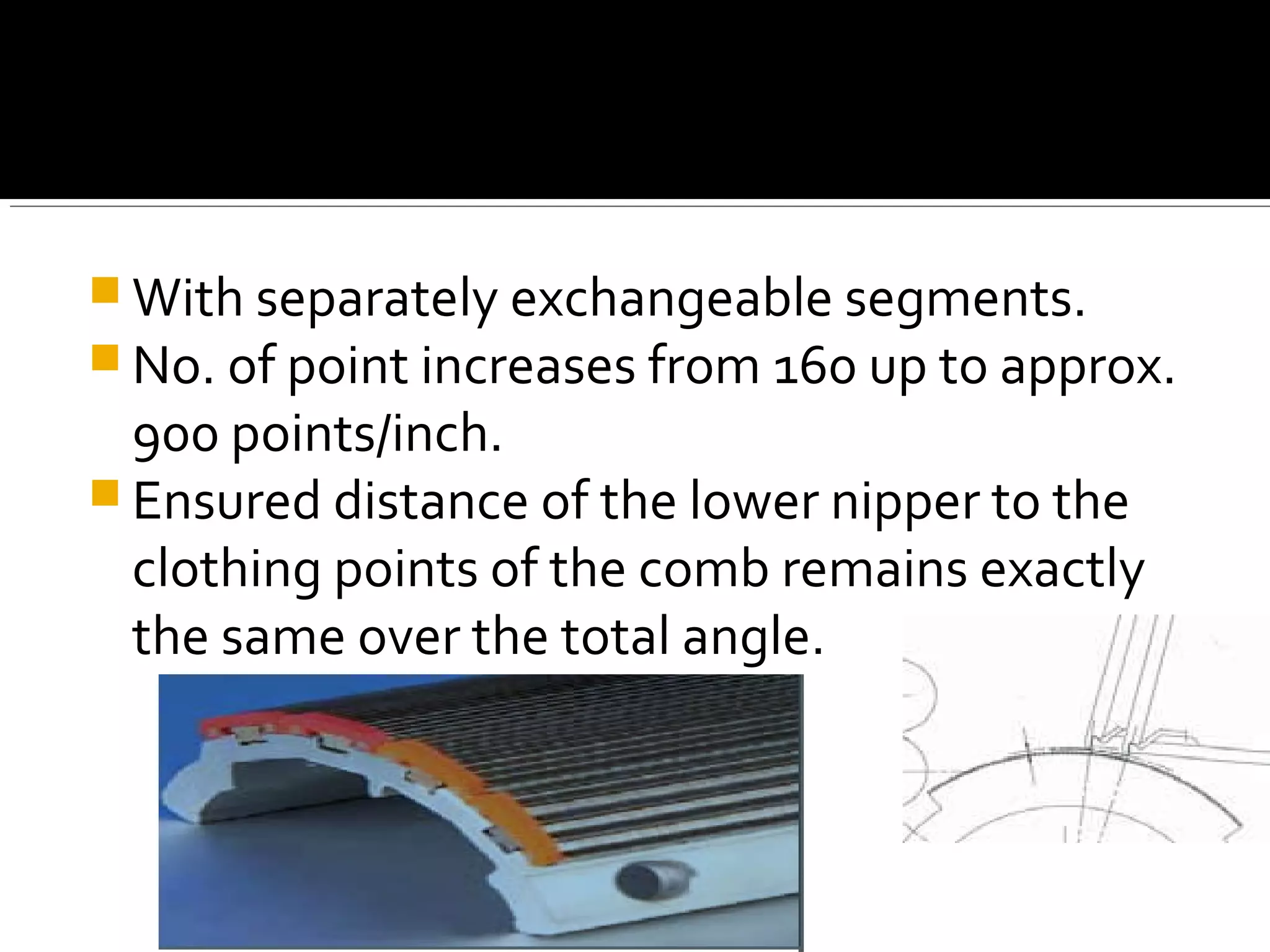

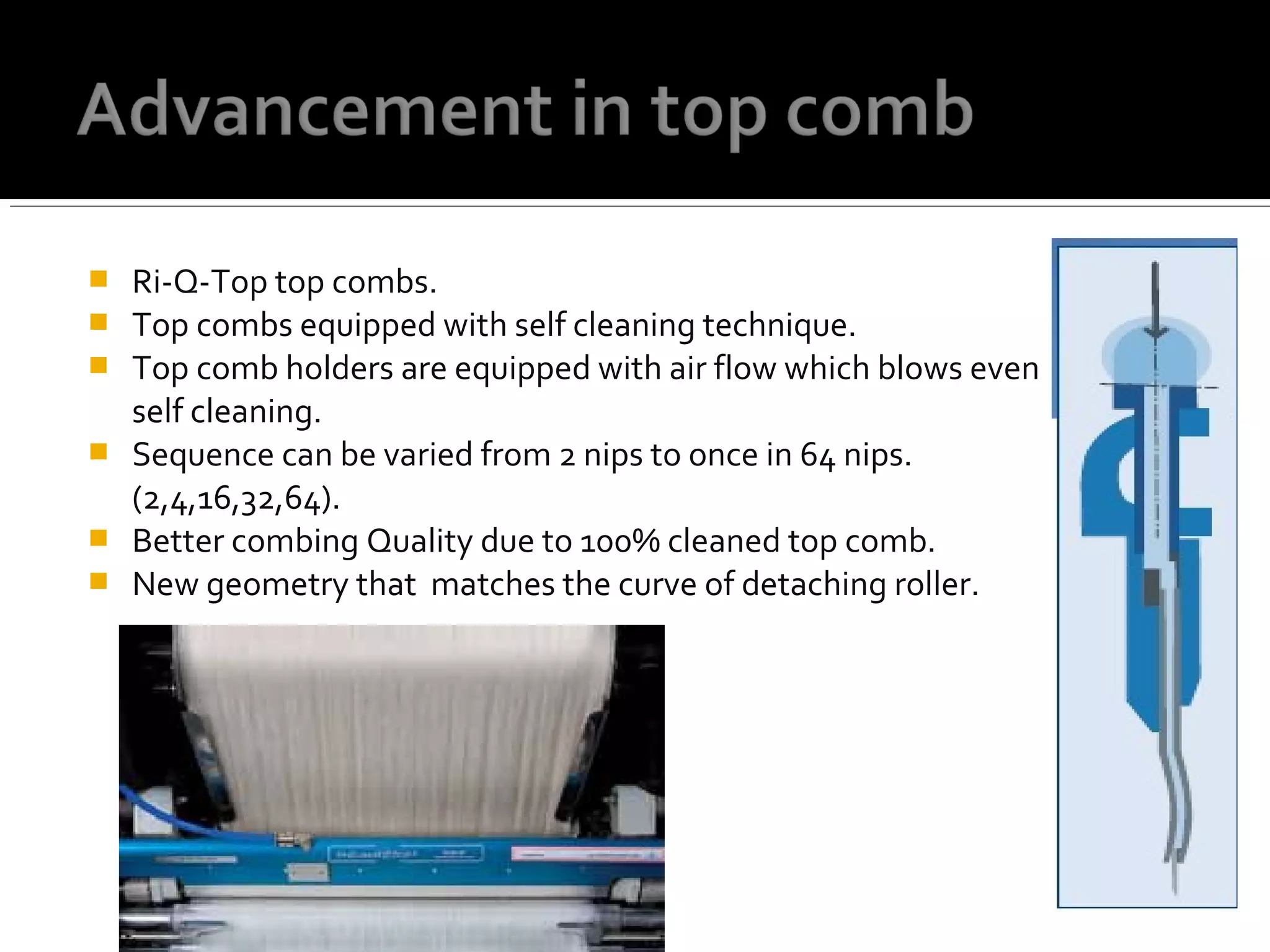

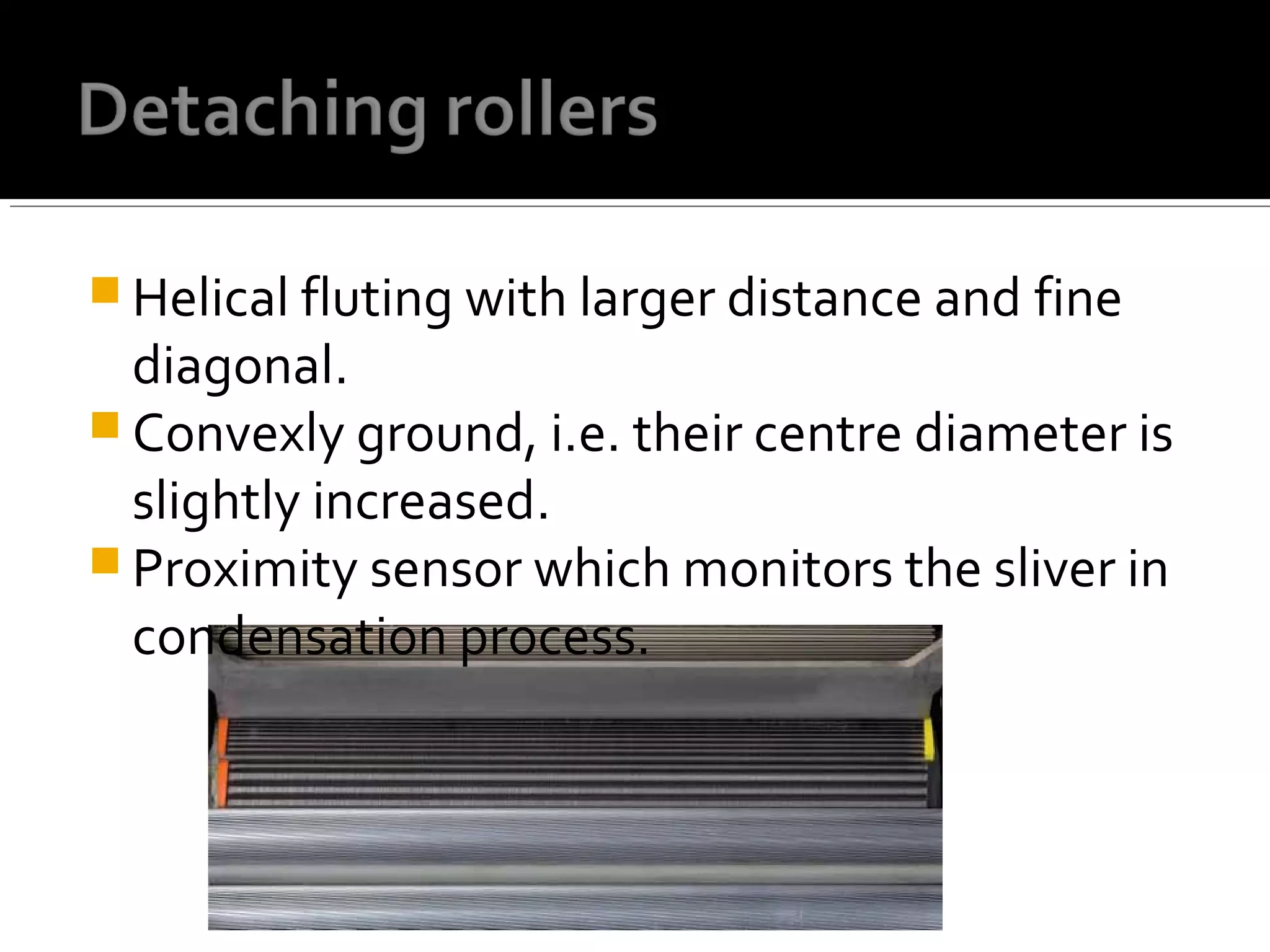

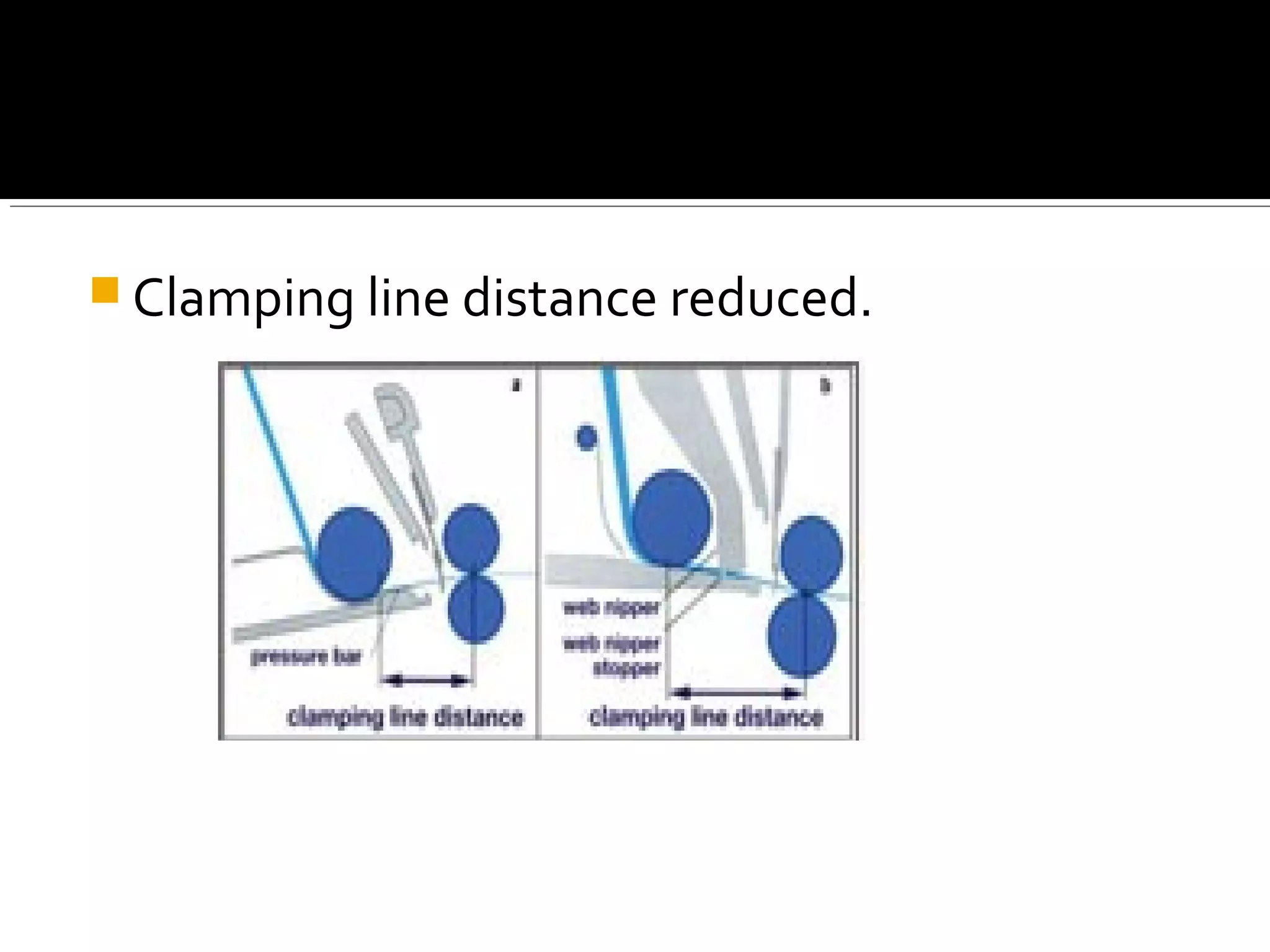

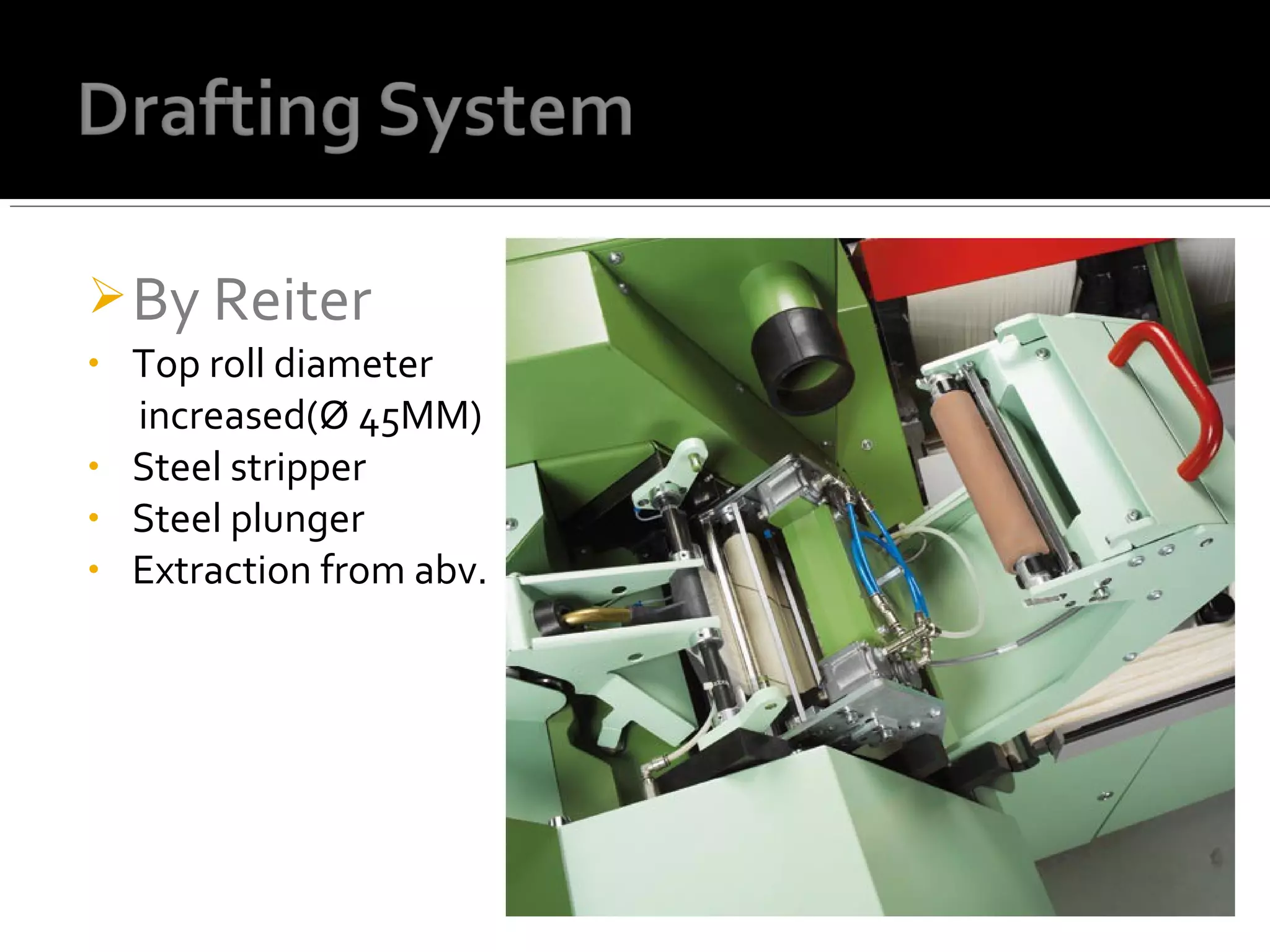

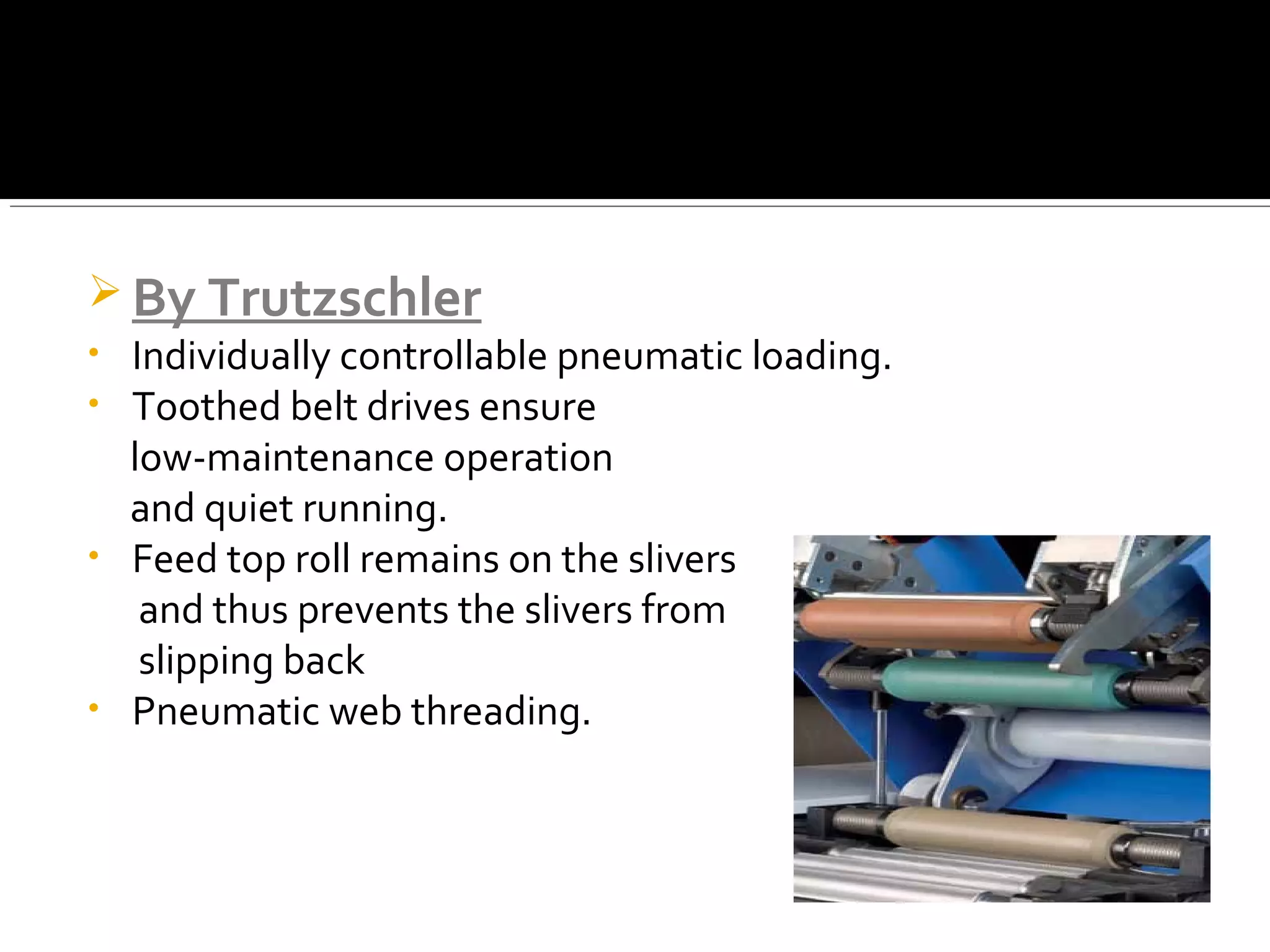

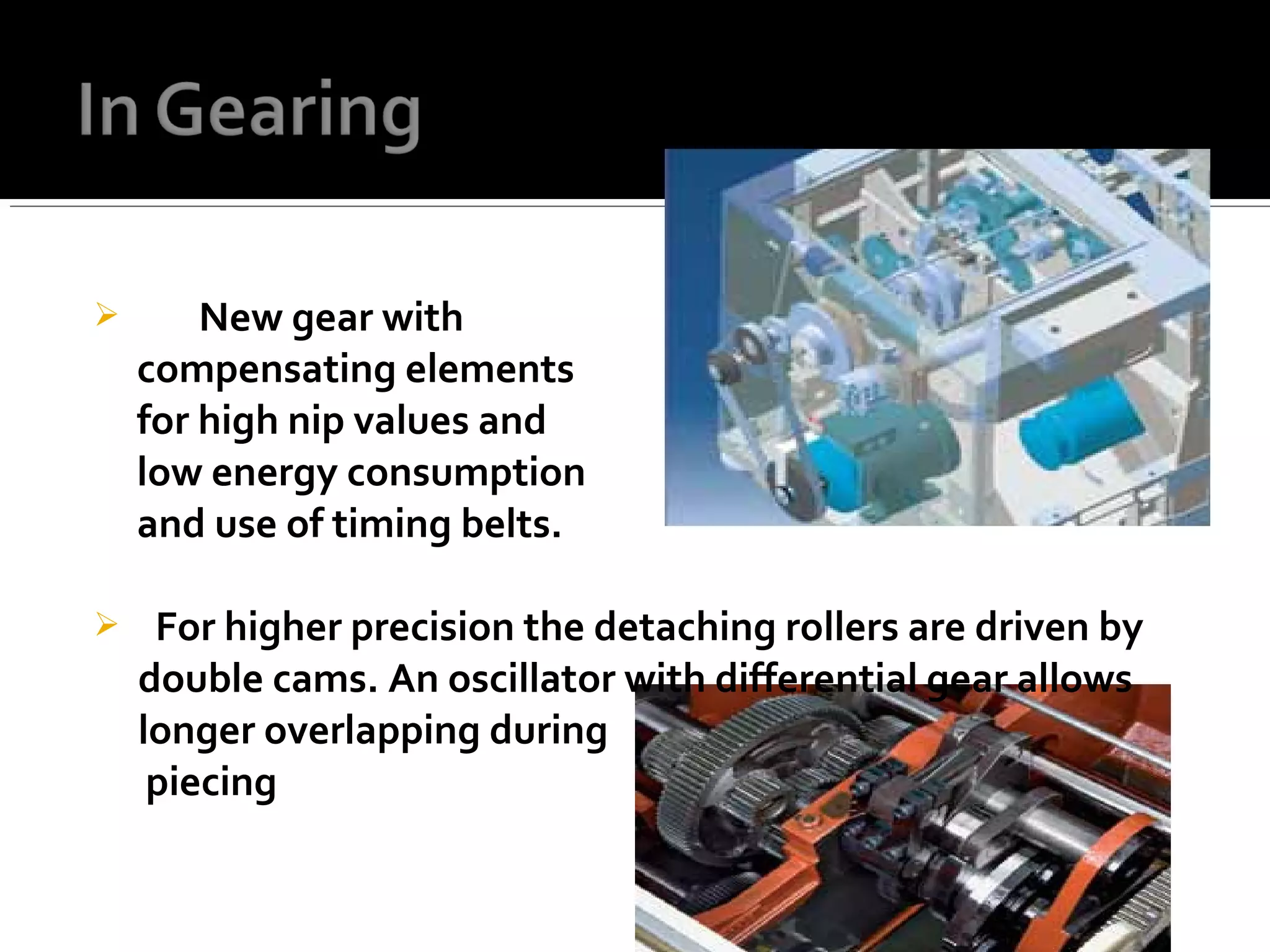

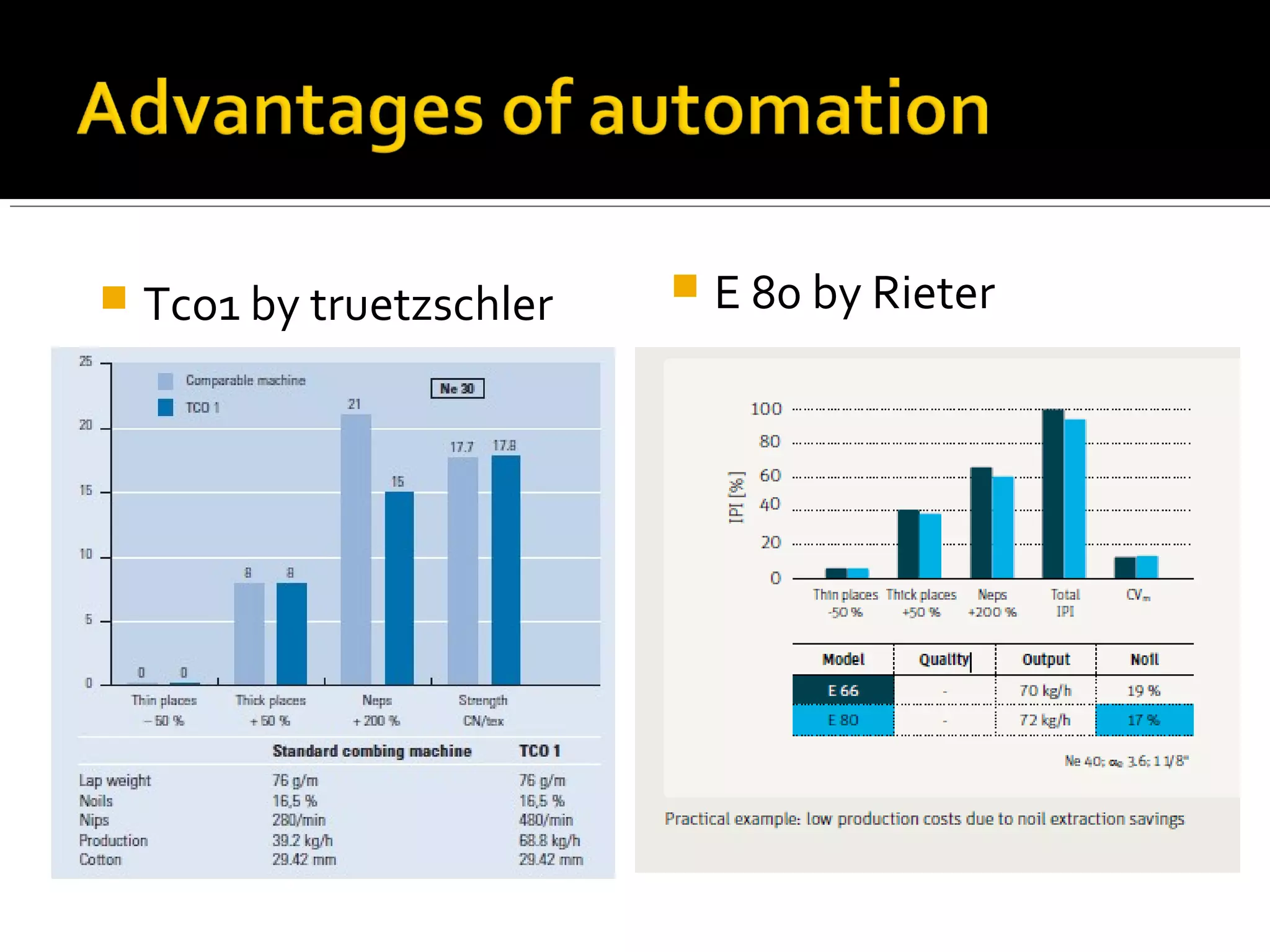

This document summarizes recent developments in combers, which prepare cotton fibers for spinning. It describes modern combers that have improvements such as higher production rates up to 520kg/hr, better fiber orientation and batt structure, even tension lapping systems, and fully automated servo trolleys. Key components like nippers, combs, and detaching rollers have also been updated with advances like reduced vibrations, self-cleaning techniques, and finer tooth configurations for improved combing quality and fiber waste reduction.