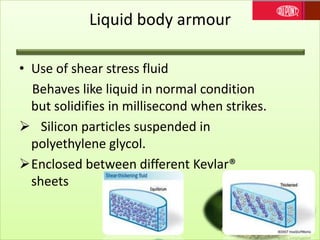

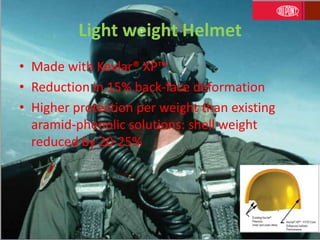

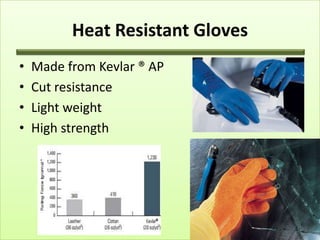

Kevlar fiber is a para-aramid fiber known for its high strength-to-weight ratio and cut resistance. Developments include new Kevlar fibers that are 15% stronger and reduce backface deformations. Kevlar is used in aerospace, marine, body armor, helmets, vehicles, oil/gas, and optics due to its light weight and high strength properties. New applications include liquid body armor using Kevlar sheets enclosing shear stress fluid and heat resistant gloves.