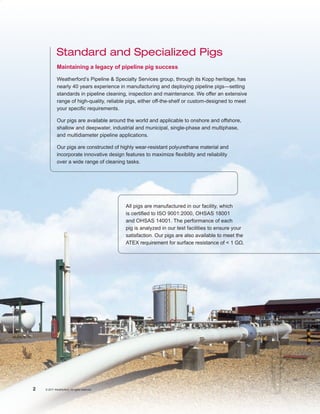

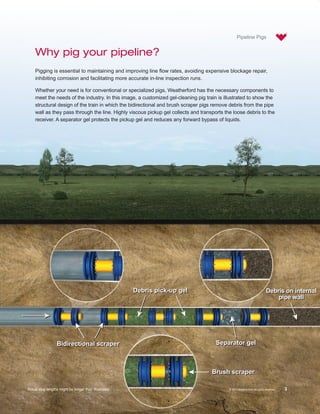

The document discusses Weatherford's extensive experience in manufacturing and deploying pipeline pigs for over 40 years. It offers a range of standard and specialized pigs for various pipeline cleaning, inspection, and maintenance needs. Standard pigs include bidirectional pigs, cup pigs, and poly/foam pigs. Specialized pigs are designed for challenging conditions and include dual-diameter, contour, gauging, D-scaling, and D-waxing pigs. All pigs are manufactured according to rigorous quality standards and testing procedures.