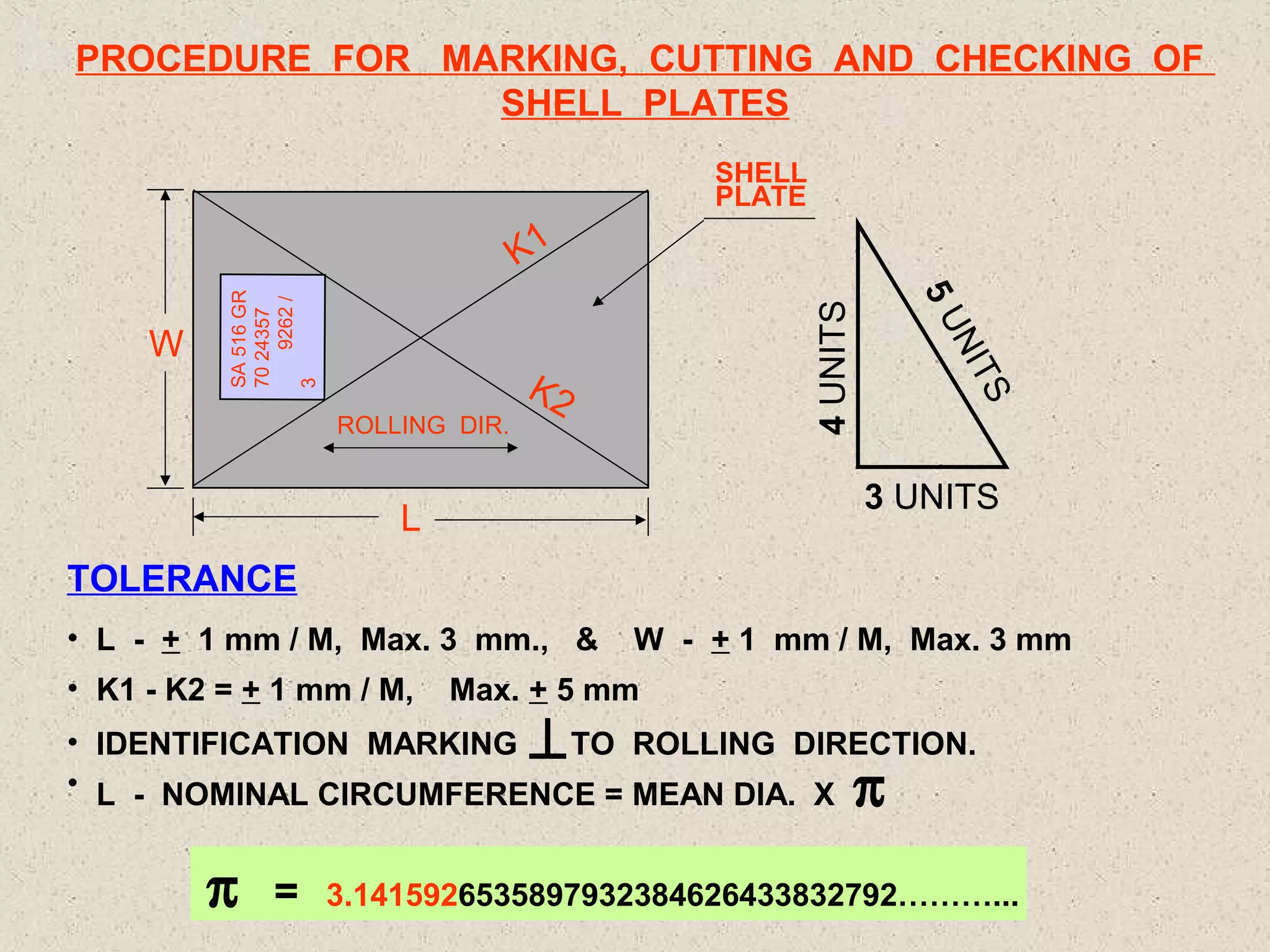

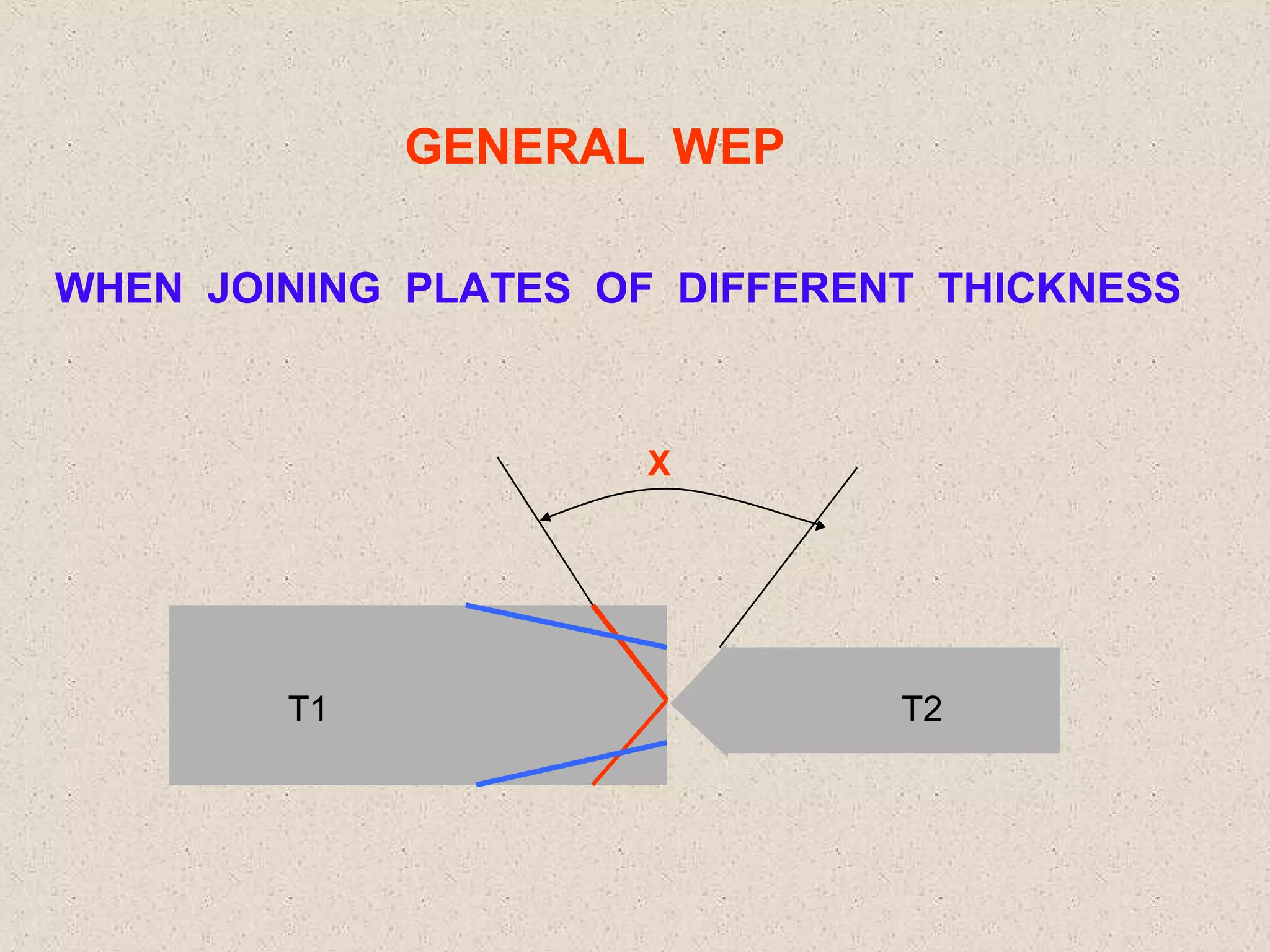

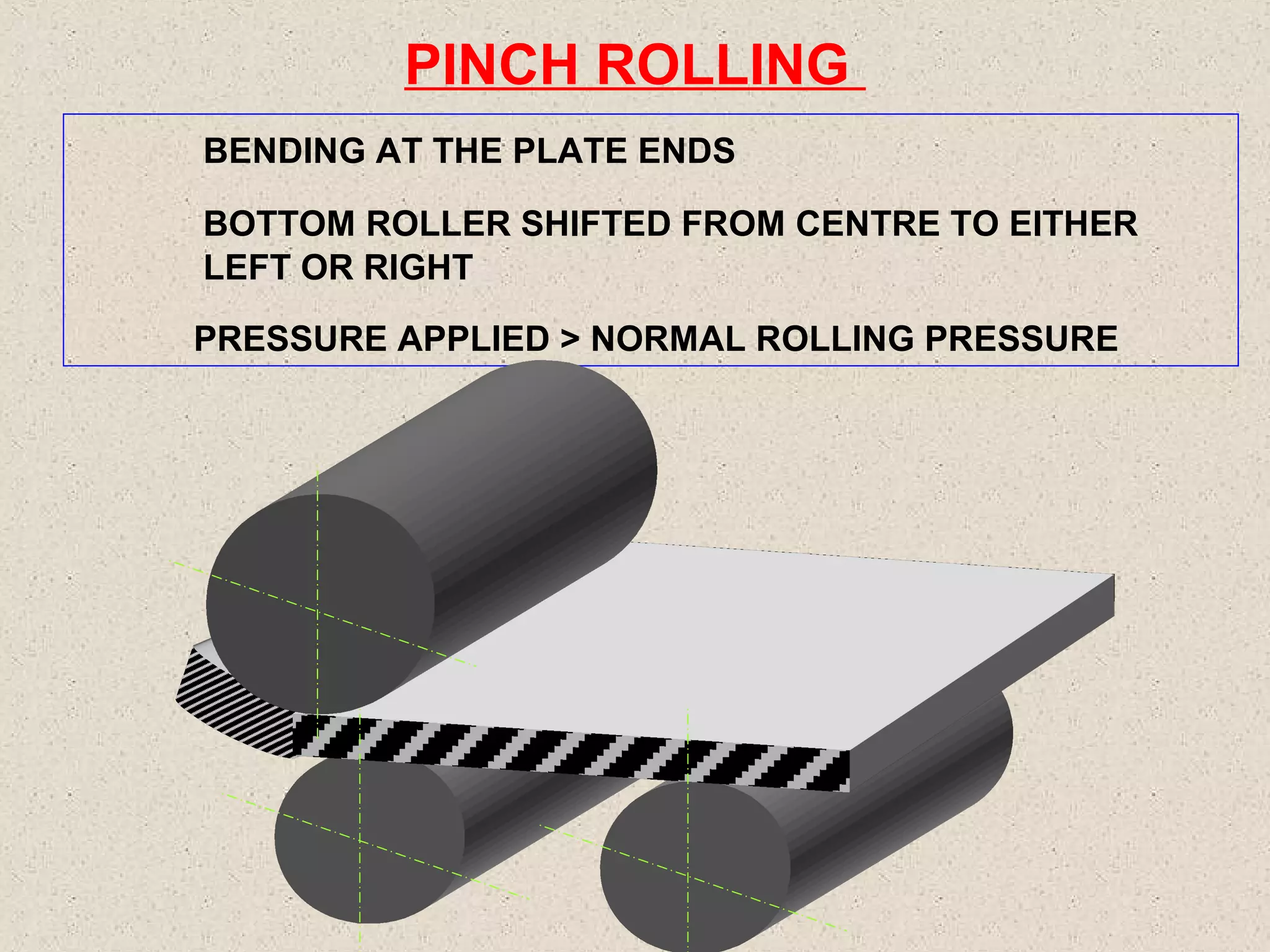

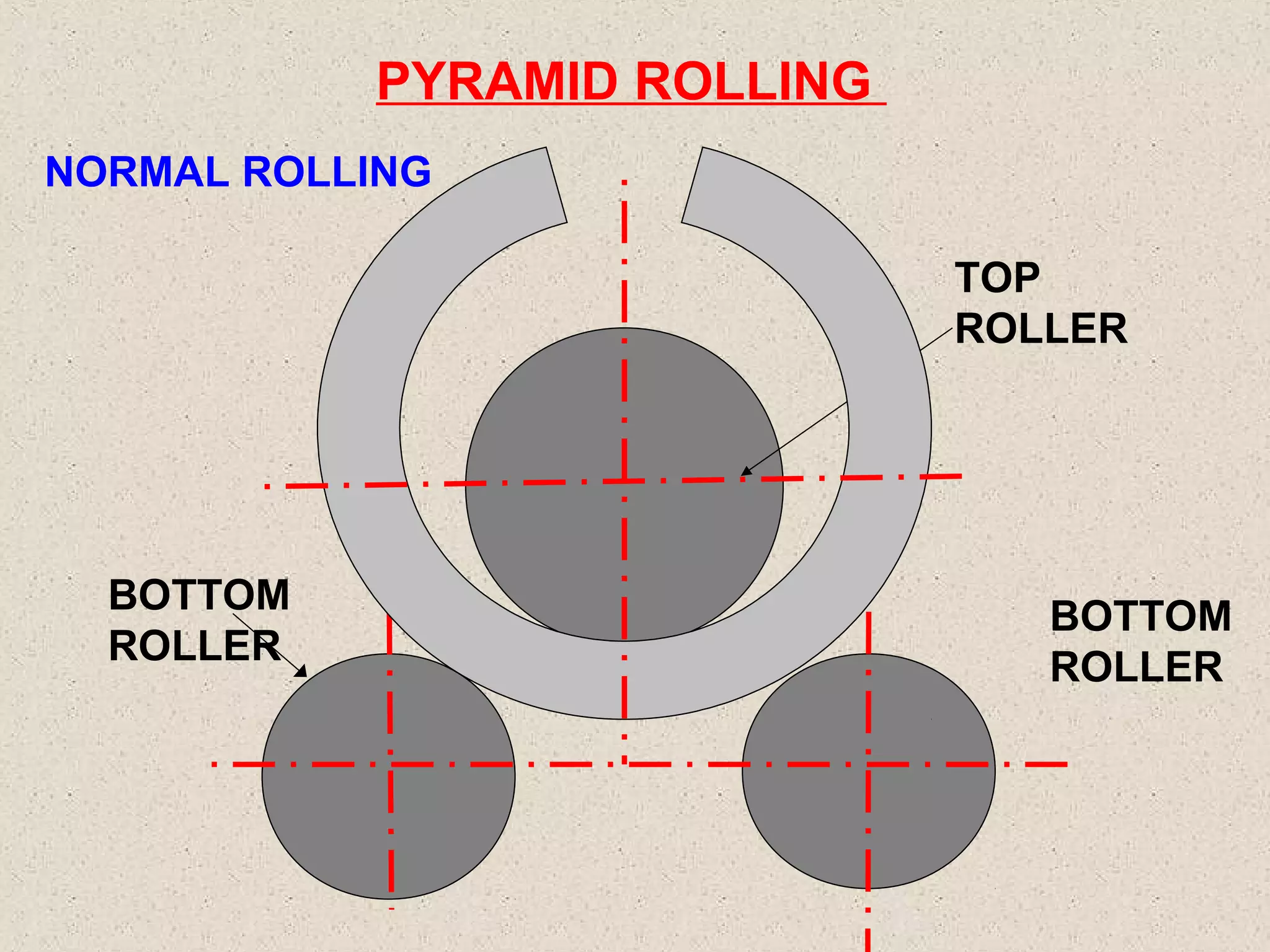

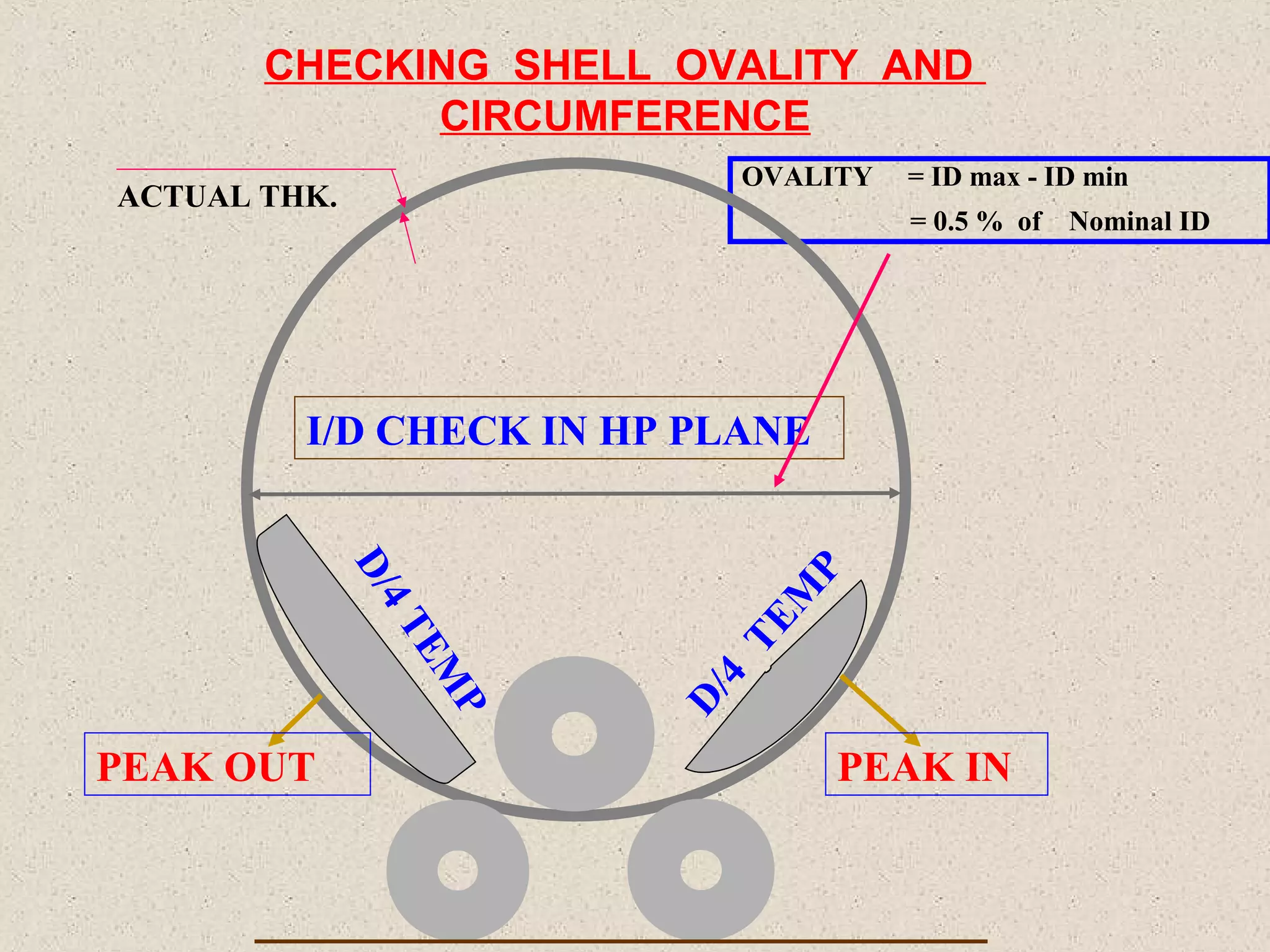

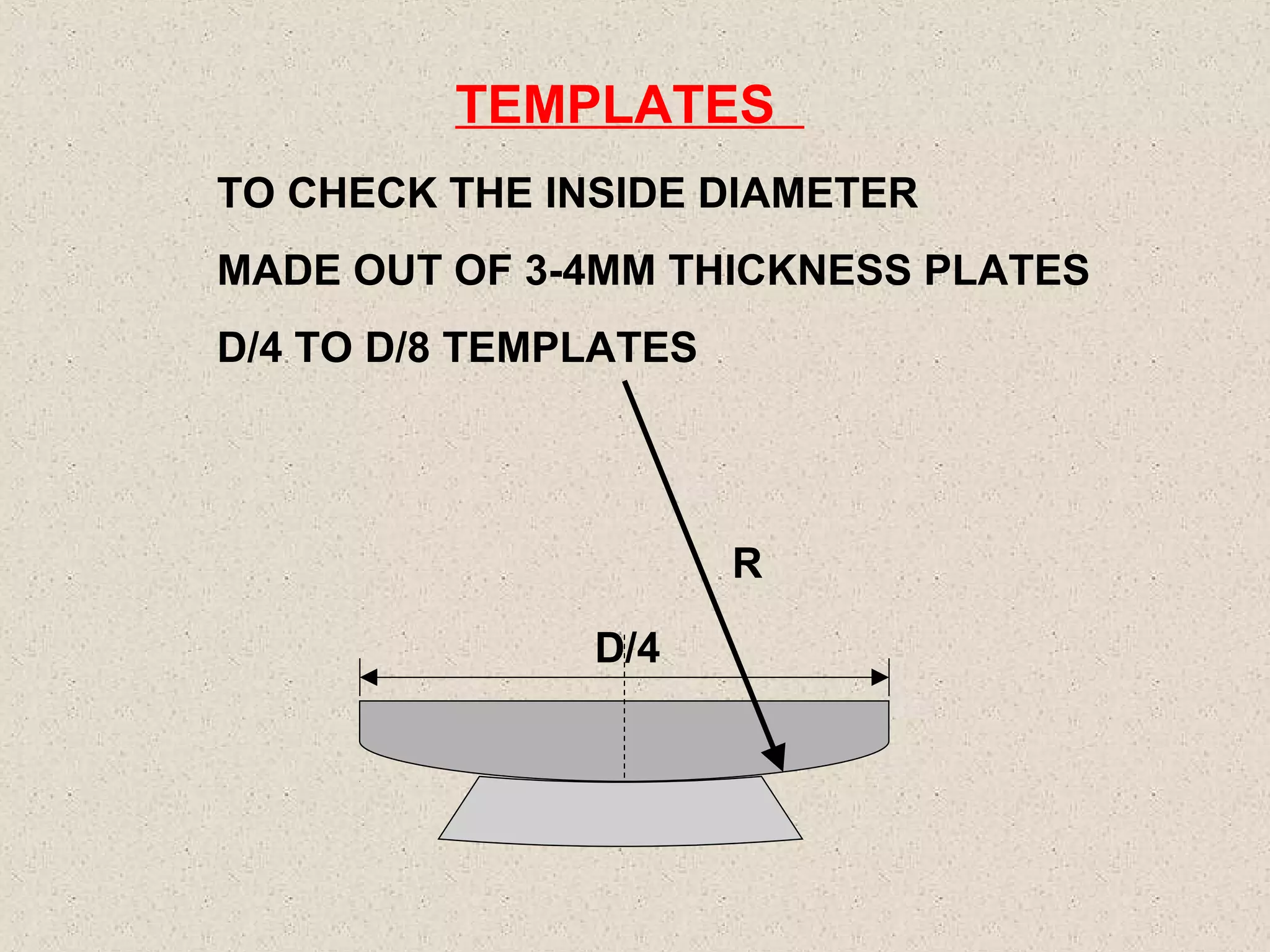

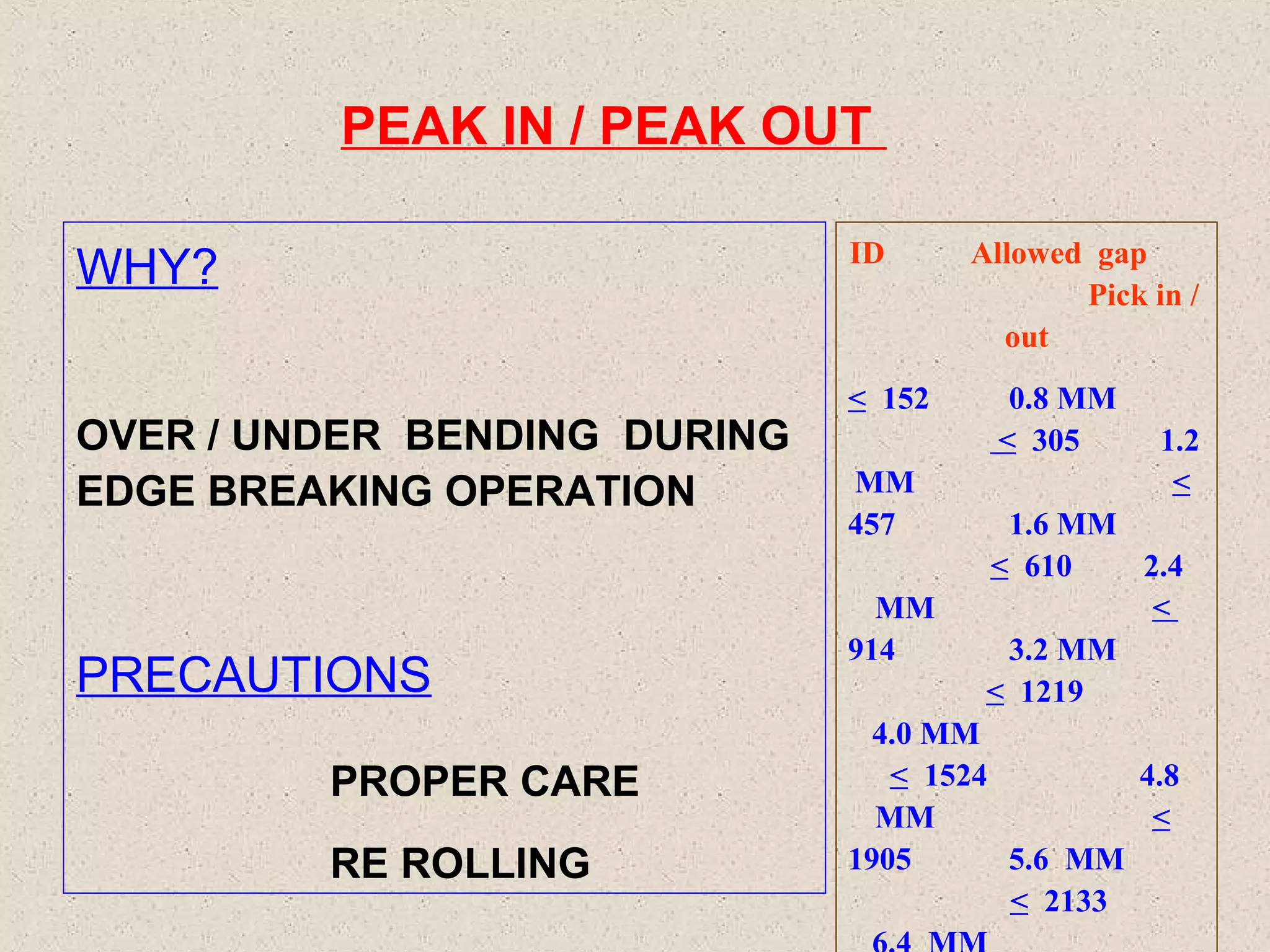

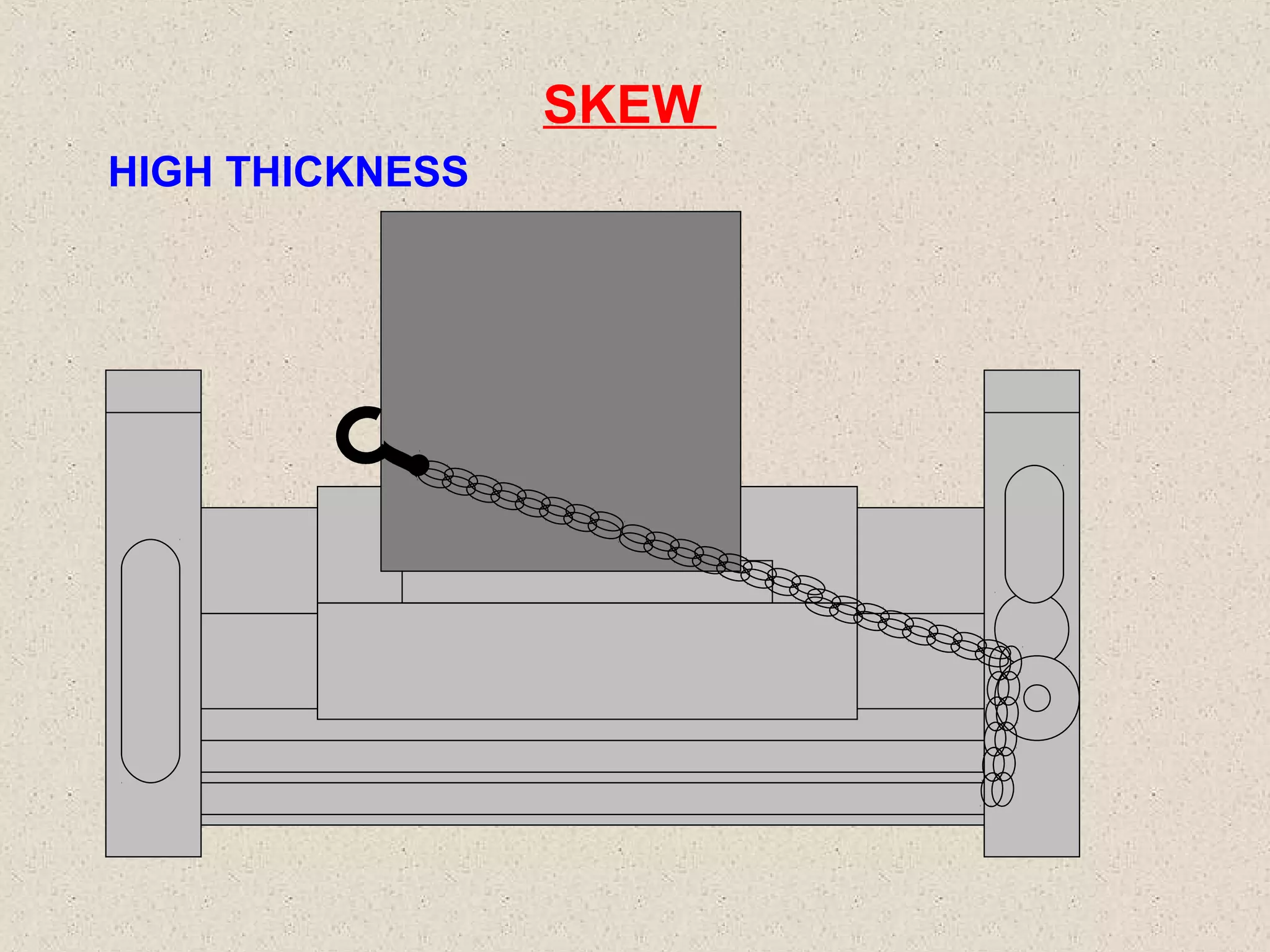

This document provides procedures and guidelines for marking, cutting, checking, and rolling of shell plates. It discusses marking plates with identification parallel to the rolling direction. It also summarizes methods of rolling including pinch rolling, pyramid rolling, cold rolling, warm rolling, and hot rolling. The document outlines tolerances for checking shell ovality, circumference, peak in/out, and skew. It emphasizes the importance of good engineering practices like checking diagonals and templates.