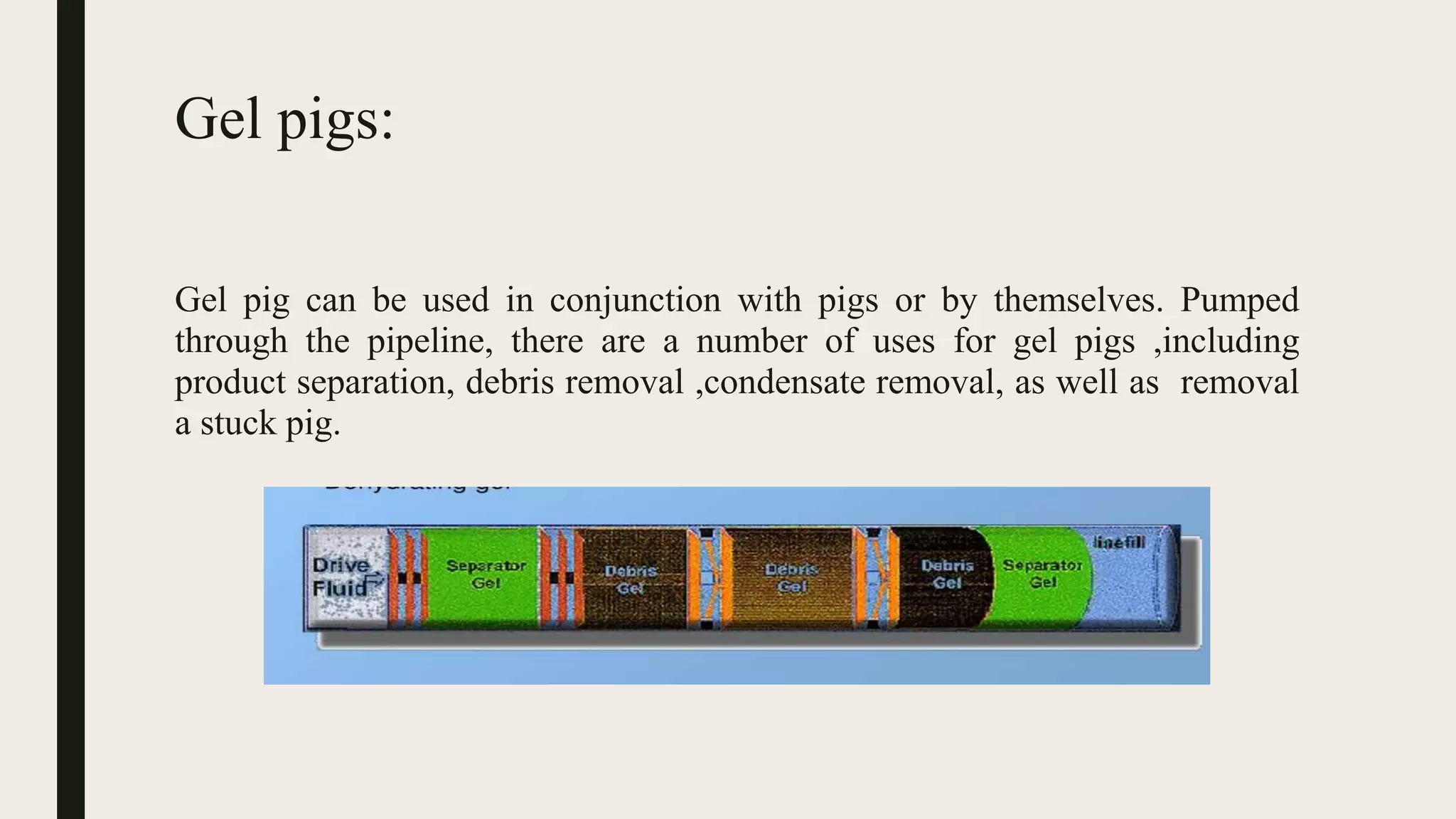

Pigging is a process used to clean and maintain pipelines. It involves pushing devices called "pigs" through pipelines to remove deposits, decrease surface roughness, and decrease friction. There are different types of pigs for different applications, such as foam pigs for general cleaning, solid cast pigs for ruggedness, and intelligent pigs for inspections. Factors like the pipeline contents, velocity, and characteristics are considered to select the appropriate pig. Pigging is used to maintain continuous operations, ensure pipeline integrity, and obtain maximum efficiency by removing debris and deposits that restrict flow.