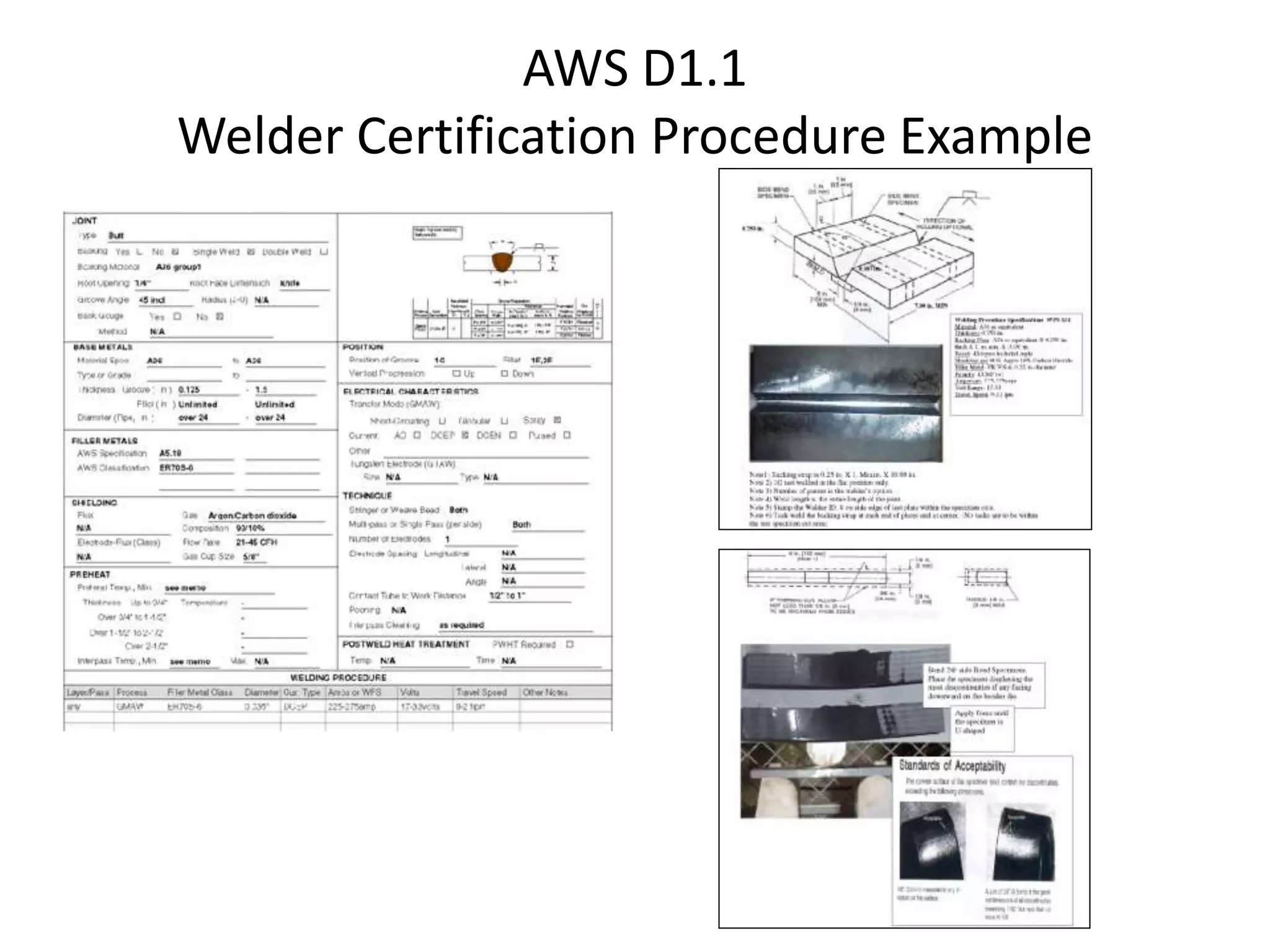

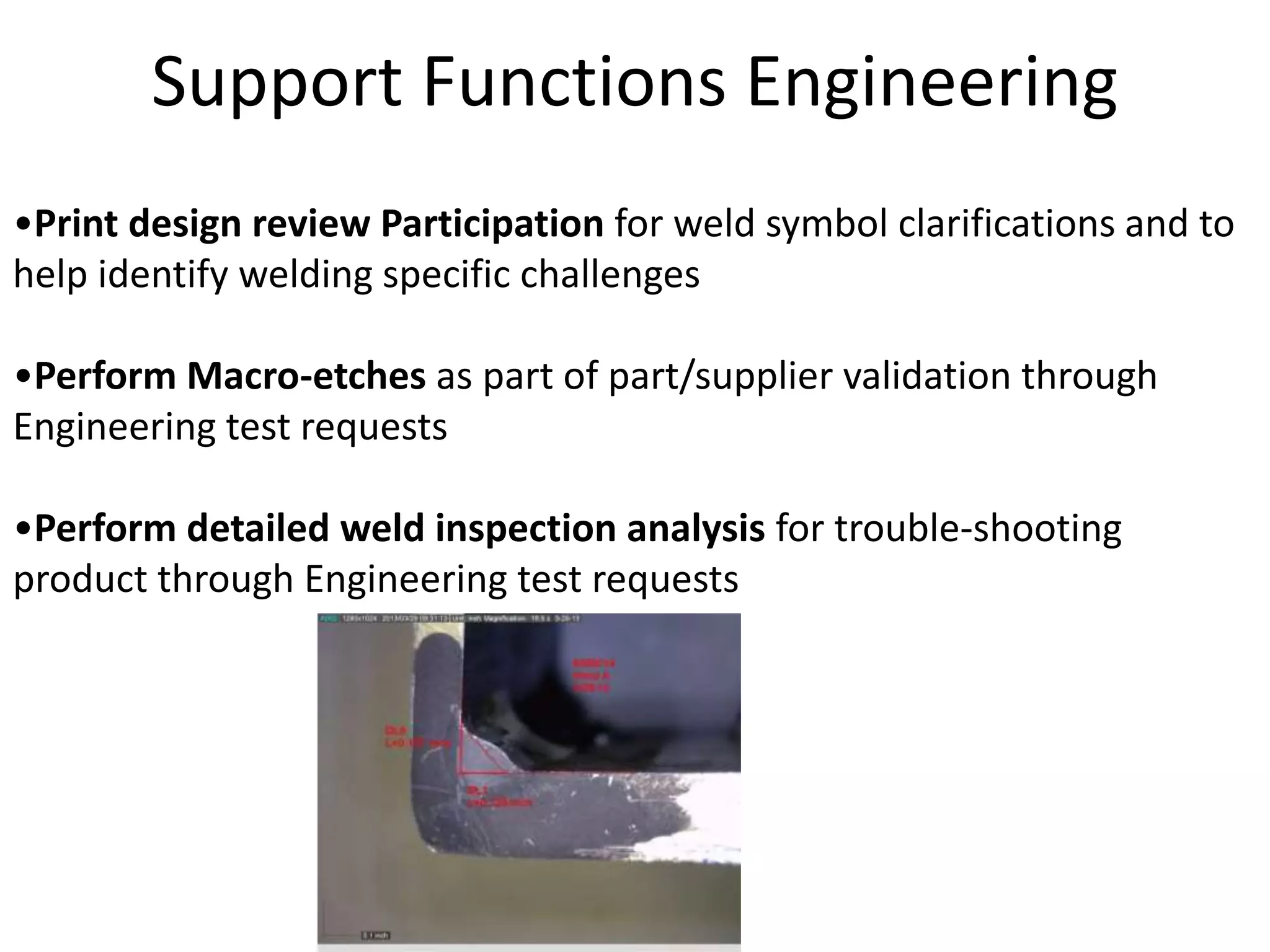

This document summarizes the qualifications and responsibilities of a Welding Technician/AWS CWI, CWE. The individual has over 30 years of experience as a certified welder and is certified as a Welding Inspector and Educator. Responsibilities include providing weld training, managing certification programs, performing inspections, analyzing defects, and supporting various functions like quality assurance, engineering, maintenance, safety, and more. Mandatory requirements include communication, teaching, and interpersonal skills.