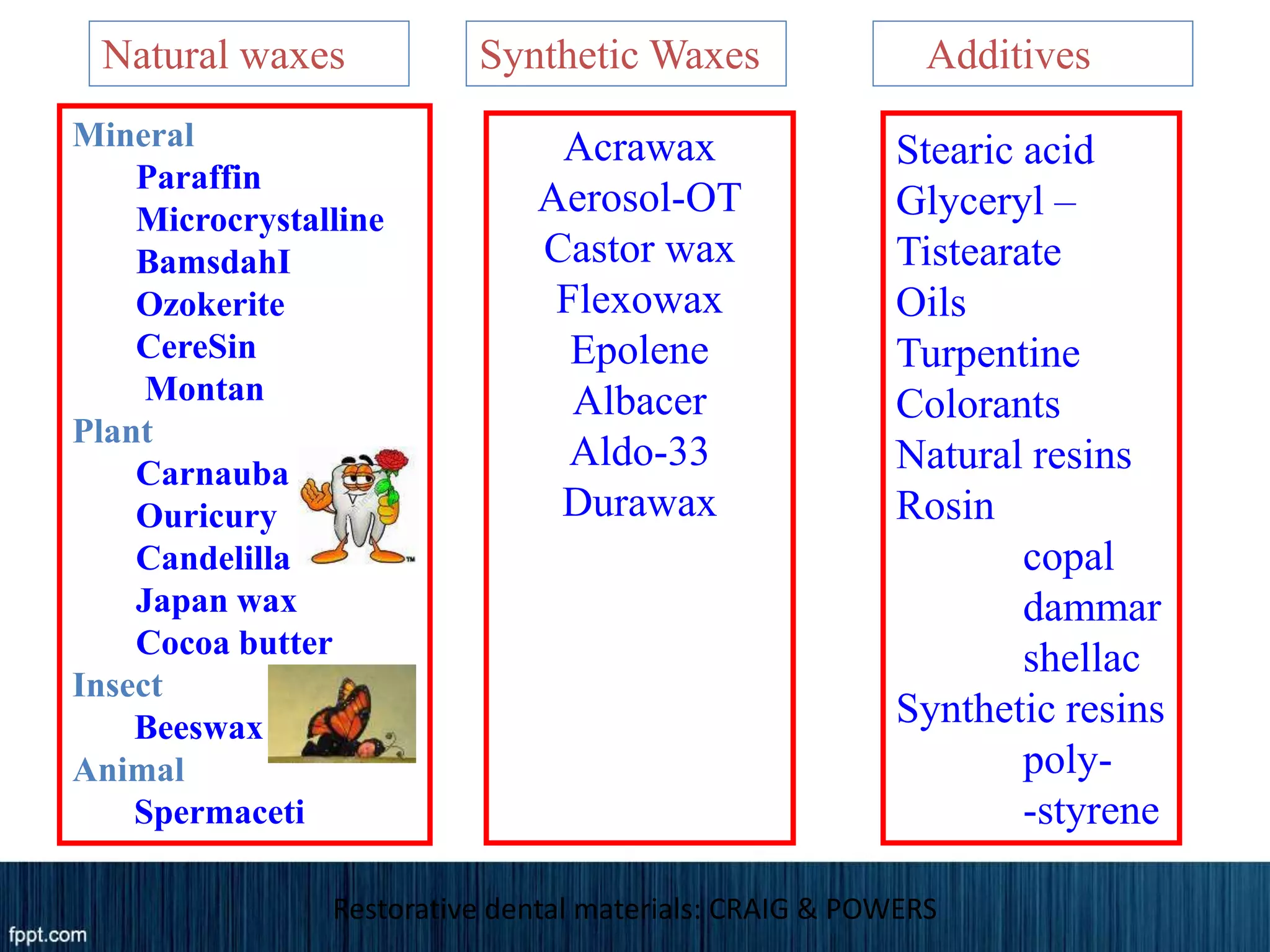

This document discusses various types of waxes used in dentistry, their compositions, properties, and applications. It covers natural waxes like beeswax, paraffin wax, and carnauba wax as well as synthetic waxes. Key waxes discussed include inlay pattern wax, casting wax, and baseplate wax. Inlay pattern wax is a blend designed to have good flow properties at mouth temperature as well as dimensional stability when solidified. Casting wax is used to make patterns for crowns and bridges and must vaporize completely during the burnout process. Baseplate wax is pink-colored and formulated to be soft enough to establish jaw relations during initial denture fabrication.