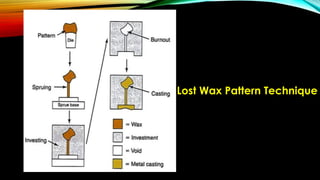

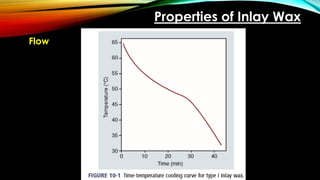

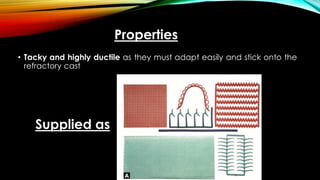

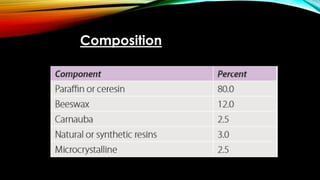

The document discusses dental wax, including its history, components, classification, properties and uses. It provides details on the different types of waxes such as paraffin wax, beeswax, carnauba wax and their properties. Pattern waxes are specifically used to create wax patterns that are later replaced with more durable materials through lost wax casting. Inlay casting wax is among the oldest waxes used in dentistry to create wax patterns for inlays, crowns and fixed dental prostheses.