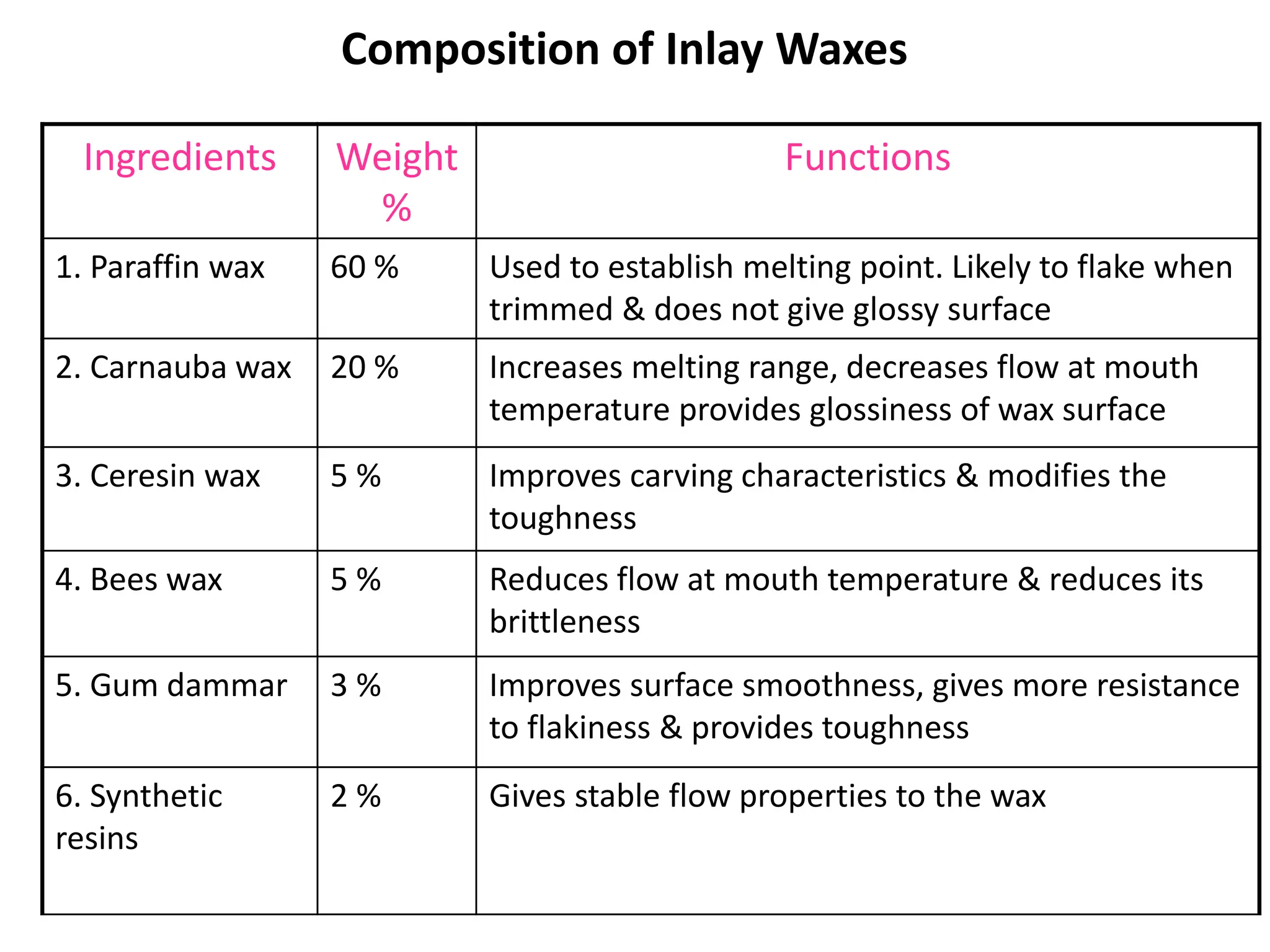

The document presents a comprehensive overview of dental waxes, including their definition, history, and classification. It details the characteristics, composition, and properties of various types of waxes used in dentistry, such as pattern, processing, and impression waxes. The conclusion underscores the importance of waxes in dental applications, emphasizing their role in creating impressions, patterns, and prosthetic devices.