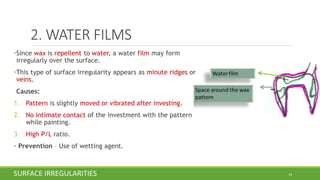

This document discusses various types of casting defects that can occur during dental prosthesis fabrication. The main types discussed are distortion, surface roughness/irregularities, porosities, and incomplete/missing details. Distortion can be caused by mishandling wax patterns or uneven investment expansion. Surface issues result from improper investing techniques or foreign substances in the mold. Porosities form due to solidification shrinkage, trapped gases in the alloy, or improper venting of the mold. Following investing and casting best practices can help prevent most defect issues.