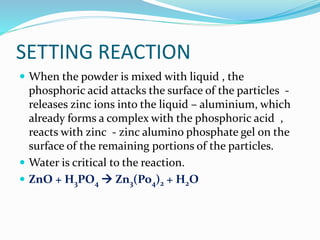

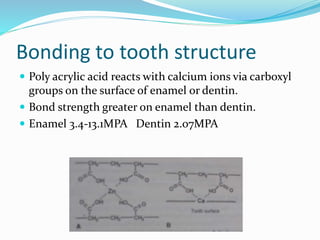

This document summarizes three types of dental cements: zinc phosphate cement, zinc polycarboxylate cement, and zinc oxide eugenol cement. It describes the introduction, composition, setting reaction, properties, manipulation and applications of each cement. Zinc phosphate cement is the oldest luting cement and involves a reaction between zinc oxide and phosphoric acid. Zinc polycarboxylate cement bonds to tooth structure through a reaction between polyacrylic acid and calcium ions. Zinc oxide eugenol cement sets through a reaction between zinc oxide, water and eugenol, and has sedative properties making it the least irritating to dental pulps.