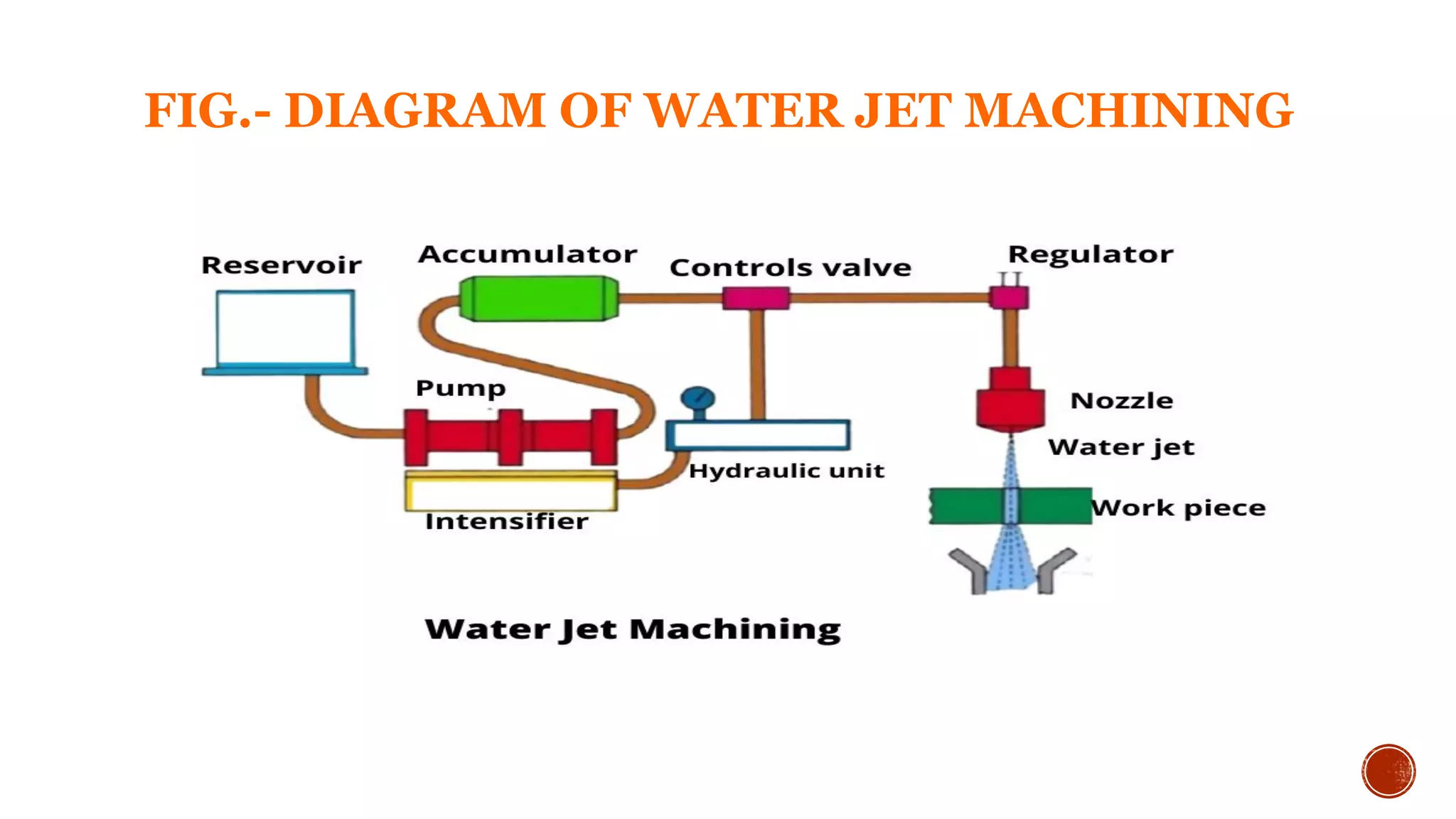

Water jet machining is a non-traditional machining process that uses a high-velocity water jet to cut and machine soft, non-metallic materials. It works by removing material using the erosive power of a finely focused water jet. The water is pumped to high pressures, then passed through a nozzle to create the jet. Key parameters that affect the process include standoff distance, fluid pressure, feed rate, and nozzle diameter. It can precisely cut a variety of materials like wood, rubber, and composites, with advantages being low heat impact, clean cuts, and ability to cut explosives safely. However, it is limited to soft materials and not suitable for high volume production.