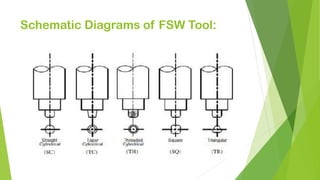

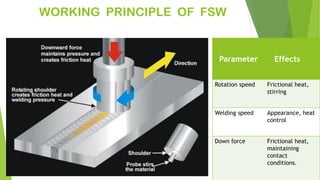

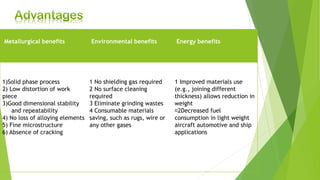

The document discusses friction stir welding (FSW), a method of joining materials through frictional heating and mechanical deformation, notably advantageous for aluminum and its alloys. It covers the classification of welding, the design and materials of FSW tools, as well as the environmental and metallurgical benefits of FSW. The conclusion highlights its vital applications in aerospace and marine industries, while noting that FSW is currently limited to specific metals but is promising for broader applications.