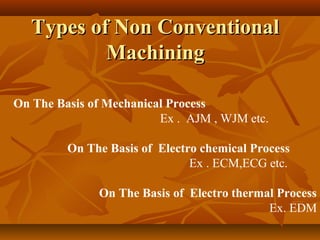

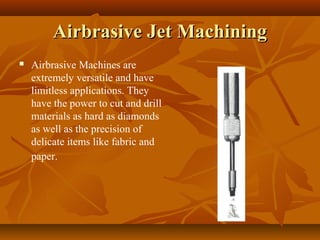

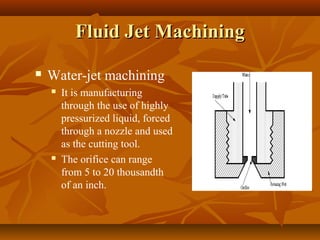

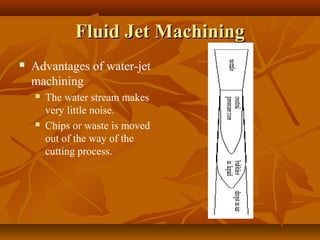

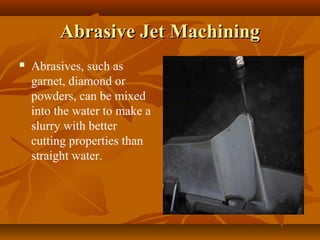

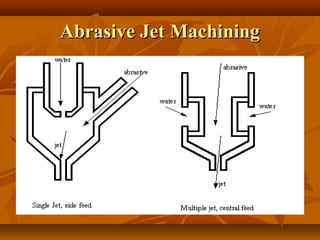

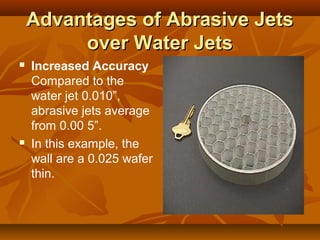

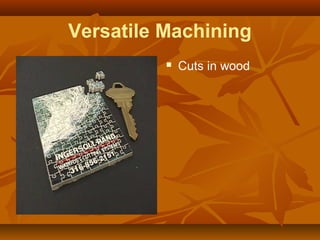

The document discusses non-conventional machining processes, specifically various types of jet machining. It describes abrasive jet machining where abrasives are mixed with water to cut materials. Airbrasive jet machining uses high pressure air and powder to cut. Fluid jet machining uses high pressure liquid through a nozzle. Water is most common but other fluids can be used. Jet machining has advantages like burrless cuts, omnidirectional cutting, and no heat affected zones. It is suitable for brittle materials, composites, and producing long tapered walls in deep cuts.