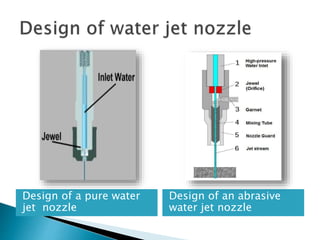

This document discusses water jet cutting technology. It describes how water jets work by using high-pressure water or water with abrasive particles to cut materials. Water jets can cut with precision and versatility across many materials without generating heat. They have grown in popularity for applications in architecture, aerospace, manufacturing, automotive and electronics due to their safety, lack of mechanical stress on materials, and environmental friendliness. While generally effective, water jets are less suitable for cutting thick or hardened materials.