Conventional Wastewater Treatment PROCESS.pdf

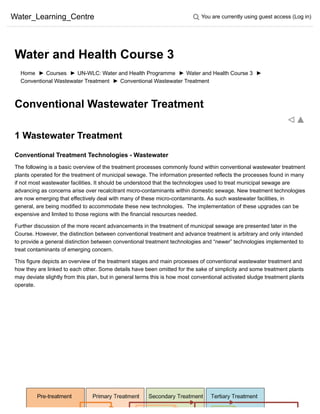

- 1. Water_Learning_Centre You are currently using guest access (Log in) Home ► Courses ► UN-WLC: Water and Health Programme ► Water and Health Course 3 ► Conventional Wastewater Treatment ► Conventional Wastewater Treatment Conventional Wastewater Treatment 1 Wastewater Treatment Conventional Treatment Technologies - Wastewater The following is a basic overview of the treatment processes commonly found within conventional wastewater treatment plants operated for the treatment of municipal sewage. The information presented reflects the processes found in many if not most wastewater facilities. It should be understood that the technologies used to treat municipal sewage are advancing as concerns arise over recalcitrant micro-contaminants within domestic sewage. New treatment technologies are now emerging that effectively deal with many of these micro-contaminants. As such wastewater facilities, in general, are being modified to accommodate these new technologies. The implementation of these upgrades can be expensive and limited to those regions with the financial resources needed. Further discussion of the more recent advancements in the treatment of municipal sewage are presented later in the Course. However, the distinction between conventional treatment and advance treatment is arbitrary and only intended to provide a general distinction between conventional treatment technologies and “newer” technologies implemented to treat contaminants of emerging concern. This figure depicts an overview of the treatment stages and main processes of conventional wastewater treatment and how they are linked to each other. Some details have been omitted for the sake of simplicity and some treatment plants may deviate slightly from this plan, but in general terms this is how most conventional activated sludge treatment plants operate. Water and Health Course 3

- 2. Pre-treatment is intended to remove large debris and grit from the raw wastewater. A comminutor shreds the solids in preparation for movement of the waste to primary treatment. Primary treatment is intended to remove the settable solids and floatable materials from the effluent. Secondary treatment biologically digests soluble organics and removes refractory solids as sludge to be further treated in a separate sludge digestion process. NOTE: some WWTPs provide only secondary treatment and once the secondary treatment is achieved the effluent is disinfected, dechlorinated and released to the environment (typically to a nearby surface water body). For those WWTPs offering tertiary treatment the secondary effluent is transferred to subsequent tertiary treatment processes. Tertiary treatment removes additional unwanted constituents in order to meet the regulatory requirements of the jurisdiction. It is important to note that not all of the tertiary processes listed in this diagram are necessarily operative at each facility. Tertiary treatment is often customized to meet specific treatment objectives. Undigested solids (sludge) are further digested in a different process. This is typically accomplished through anaerobic digestion with heat, but may also be done aerobically. Activated Sludge Treatment Process The two most common treatment processes for municipal wastewater are: 1) Activated Sludge 2) Trickle Filter The activated sludge process is typically the preferred method. The activated sludge utilizes microbial degradation for the digestion of soluble organic constituents within primarily treated effluent. The trickle filter also utilizes microbial degradation for the same purposes. However, in this process the primarily treated effluent is sprayed onto a filter bed composed of course gravel or crushed stone. A bacterial community develops on the substrate to form a biofilm These filters require general maintenance for they will plug as the biofilms thicken

- 3. the substrate to form a biofilm. These filters require general maintenance for they will plug as the biofilms thicken. Activated Sludge Wastewater Treatment Plant Providing Secondary Treatment This figure provides more detail regarding the layout of a typical secondary wastewater treatment plant. Note that it is typical to have two primary clarifiers and two secondary clarifiers. Also note that two heated anaerobic digesters are used for the digestion of the sludge. This schematic also illustrates the transfer of returned activated sludge (from secondary clarifiers) to the aeration tank (in this diagram called the biological or chemical treatment tank) and wasted sludge (from secondary clarifiers) and the transfer of the filtrate (from the anaerobic digesters) back to the flow equalization tank. Trickle Filters This is an example of what a trickle filter looks like. Most WWTPs do not use this process for biological treatment, but instead use the activated sludge process.

- 4. Trickling Filter Pre-Treatment Waste Water The intent of the pre-treatment stage is to remove those materials that could either damage the facility. Shredding of the solids into smaller sizes helps in the separation of solids and effluents and later in the microbial digestion of this material. The grit chambers remove smaller objects such as broken pieces of glass, sand, silt and pebble that could damage or plug the system. Another design that is sometimes used is an aerated grit chamber. In an aerated grit chamber, air bubbles are injected into a wastewater basin to force a spiral, or rolling, flow. The air bubbles are supposed to strip organic material off the surfaces of the inert grit as well as maintain the proper flow rate for the grit to settle to the bottom of the tank, usually with a clam bucket. The flow volumes entering the wastewater treatment plant are typically uneven with mid-morning periods having the greatest flows. The equalization chamber helps to balance the flows to ensure a constant and even flow is delivered for treatment. In this way, the system processes are not disrupted. Primary Treatment The primary clarifier is the settling tank that receives the pre-treated raw sewage. The primary clarifier can also be called the “settling tank” or the “sedimentation & floatation unit”.

- 5. Often the effluent will flow through two primary clarifiers to improve separation of solids, floatables and effluent. The clarifiers can be circular or rectangular in shape but both operate on the same principle of gravitational separation of the different phases. Secondary Treatment: Aeration Tank When wastewater enters the aeration tanks, it is mixed with the activated sludge to form a mixture of sludge, carrier water, and influent solids (called mixed liquor). These solids come mainly from the discharges from homes, factories, and businesses. The activated sludge which is added contains many different types of helpful living organisms that were grown during previous contact with wastewater. Most primary effluents still have between 40 and 60 percent of the original pollutants present. Some of this may be dissolved in the wastewater, forming a solution. Some may consist of solid particles which are too small to settle out under gravity. These very small particles are known as colloids. The purpose of secondary treatment is to remove these dissolved and colloidal pollutants. Secondary treatment removes soluble materials that require oxygen for decay since much of the removal is via microbial digestion. The most common form of secondary treatment is biological (microbial) treatment. This means that the wastewater is exposed to living organisms such as bacteria which feed on the dissolved and colloidal matter. In doing this, they either break it down to much simpler and less harmful compounds, or use it as food to increase their own cell mass. As the microorganisms grow, they tend to clump together to form fairly large particles, which can quite easily be settled out by gravity (in a process similar to clarification) to leave a clear effluent. When it is operating properly, secondary treatment can be very effective. For example, removal of 90 to 99 percent of the suspended solids and BOD in the raw wastewater is not uncommon. The microorganisms active in this process are aerobic. They are present in all wastewaters. Extra oxygen must be supplied artificially because the concentrations of pollutants and microorganisms are so much higher in a treatment plant. The rate of purification can be increased by increasing the number (concentration) of microorganisms in contact with the wastewater. The organisms stabilize soluble or finely divided suspended solids by partial oxidation forming carbon dioxide, water, and sulfate and nitrate compounds. The remaining solids are changed to a form that can be settled and removed as sludge during sedimentation. Oxygen, usually supplied from the air, is needed by the living organisms as they oxidize wastes to obtain energy for growth. Insufficient oxygen will slow down aerobic organisms, make facultative organisms work less efficiently, and favor the pro duction of foul-smelling intermediate products of decomposition and incomplete reactions. An increase in organisms in an aeration tank will require greater amounts of oxygen. More food in the influent encourages more organism activity and more oxidation; conse quently, more oxygen is required in the aeration tank. An excess of oxygen is required for complete waste stabilization. Therefore, the dissolved oxygen (DO) content in the aeration tank is an essential control test. Some minimum level of oxygen must be maintained to favour the desired type of organism activity to achieve the necessary treatment efficiency. If the DO in the aeration tank is too low, filamentous bacteria will thrive and the sludge floc will not settle in the secondary clarifier. Also, if the DO is too high, pinpoint floc will develop and not be removed in the secondary clarifier. Therefore, the proper DO level must be maintained so solids will settle properly and the plant effluent will be clear. Secondary Treatment: Secondary Clarifier The sludge settling to the bottom of the clarifier is called the activated sludge, hence the reason why this treatment process is called an activated sludge treatment process as opposed to a trickle filter process. The activated sludge contains a mixture of living bacteria, fungi, yeast, protozoa, and worms, along with dead bacteria and organic constituents that have clumped together and have fallen out of the water column under gravitational forces. When the sludge is removed from the clarifier a portion is diverted back into the aeration tank and mixed with the

- 6. When the sludge is removed from the clarifier, a portion is diverted back into the aeration tank and mixed with the primary effluent (e.g., returned activated sludge). The living bacteria of the returned activated sludge then multiply rapidly and the microbial digestion of the primary effluent in the aeration tank begins again. The ratio of food (organic constituents of effluent) to organisms (activated sludge) is important in both the aeration tank and secondary clarifier to ensure proper and efficient breakdown of organic compounds. This ratio needs to be maintained and adjusted when needed in both of these tanks. Often the amount of return activated sludge removed from the secondary clarifier is not enough to lower the ratio of organisms to food in the clarifier and as such some of the activated sludge removed from the secondary clarifier is wasted, hence the name “wasted activated sludge”. Often the wasted sludge will be diverted to the flow equalization tank upstream of the primary clarifier, thus allowing the wasted sludge to undergo further treatment. The clarified secondary effluent can then undergo disinfection and dechlorination, as a final cleanup process before being released to the environment. The design of secondary treatment facilities can vary in how the secondary effluent is processed before being released to the environment. Often the effluent will be disinfected with chlorine. However, concerns over the production of harmful disinfection by-products and the potential release of chlorinated effluents into the environment have led some treatment facilities to use other methods of disinfection such as UV irradiation or ozonation. Many WWTPs will also pass the disinfected effluent through sand filters as a final clean up step before its release. Once again, some treatment facilities are moving away from sand filters, or are augmenting the sand filters with the use of membrane filtration. If chlorination was the disinfection method chosen, the chlorinated effluent will often undergo a dechlorination process to remove the added chlorine from entering the ecosystem of the receiving body. Chlorine can be removed by periods of holding, aeration or activated carbon. However, because of speed and ease, chemical means are often used. The most common chemical to add is sulphur dioxide, but other sulfur compounds can be used such as sodium sulfite, sodium bisulfite, sodium metabisulfite and sodium thiosulfate. Although secondary treatment can remove over eighty-five percent of the BOD, suspended solids and nearly all pathogens, sometimes additional treatment is required. If tertiary treatment is desired, then the primary effluents undergo additional treatments designed to meet specific treatment objectives for the facility. These tertiary treatment options have historically included treatment to reduce phosphorus and nitrogen and enhance the removal of organic waste constituents. Tertiary Treatment Phosphorous and nitrogen are two compounds generally elevated in the secondary effluents of municipal wastewaters. Both of these compounds are nutrients important for plant growth. Phosphorous in particular can cause eutrophication issues in receiving waters and thereby degrade the surrounding ecosystem. Several jurisdictions closely regulate the amount of phosphorus that can be released from municipal effluents. The choice of which parameters to treat and which treatment processes to install are generally specific to the individual treatment facility. The most common treatment processes used by most conventional treatment plants involve the following: Filtration - Secondary treatment processes are highly effective in reducing the BOD in wastewater. However, some suspended material can still remain in the effluent even after the solids have been settled out. Some of the suspended materials are microorganisms that can exert a BOD from normal respiration and decay. Sand filters are normally used to filter out this remaining material. The sand filters are often similar in design to the sand filters used in many conventional drinking water treatment plants. However, the filter material is often heavier than the drinking water filters since the wastewater filters require frequent backwashing to remove the solids filtered out of the wastewater effluent. Carbon adsorption - Soluble organics often remain in the secondary effluent, even after sand filtration. Many of these compounds are “refractory” or resistant to degradation. Adsorption of these compounds onto activated carbon is one of the common methods for removal Carbon is activated by heating in the absence of oxygen This

- 7. carbon is one of the common methods for removal. Carbon is activated by heating in the absence of oxygen. This is intended to create multiple fractures and pores and thus increase the surface area and hence adsorption sites on the carbon. After the adsorption capacity of the carbon has been exhausted, it can be restored by reheating it in the absence of oxygen. This process drives off the adsorbed organics, which can be consumed in an afterburner. Phosphorous removal - Phosphorus in wastewater is a pollutant because it encourages the growth of algae. Phosphorus removal usually involves the addition of metal salts such as ferric chloride or alum to the wastewater, mixing it in a reaction basin, and then sending the mixture to a clarifier to allow the phosphorus-containing precipitate to settle out. Nitrogen removal - Nitrogen in any soluble form is a plant nutrient and may need to be removed from the wastewater to control the growth of algae. In addition, nitrogen in the form of ammonia exerts an oxygen demand and can be toxic to fish. Nitrogen can be removed from wastewater by both biological and chemical means. The biological process is called ammonification / nitrification / denitrification and the chemical process is called ammonia stripping. Ammonification / Nitrification / Denitrification- The natural nitrification process can be forced to occur in the activated sludge process by maintaining a cell detention time of at least fifteen days. Bacteria can convert organic nitrogen (proteins, peptides, etc.) to ammonia (ammonification) and ammonia to nitrates (nitrification) and nitrates into nitrogen dioxide (denitrification). Small amounts of organic materials (such as methanol, or raw or settled sewage) could be added to provide a food source for the bacteria for this denitrification process if sufficient nutrients aren’t already available in the aeration basin. Ammonia Stripping - Nitrogen in the form of ammonia can also be removed chemically by raising the pH (often, by adding lime) to convert the ammonium ion into ammonia, which can be stripped from the water by blowing large quantities of air through the water. Newer treatment processes are now starting to emerge to provide effective treatment for emerging contaminants of concern. These contaminants are wide-ranging and include naturally occurring microcystin toxins produced by cyanobacteria, pharmaceuticals and personal care products, and other trace organic contaminants. Some of these compounds are not effectively removed with conventional treatment processes because of their physical-chemical structural properties and resistance to degradation and low affinity for absorption to particulates (including those that are associated with tertiary treatment). Some of the newer treatment processes include the use of powerful oxidants such as ozone, peroxide, UV irradiation, and membrane filtration. Many of these treatment options for wastewater are discussed in the sections of this course on advanced treatment for wastewater and advanced treatment for drinking water. The mechanisms of action for most of these advanced treatments are the same whether applied to wastewater or drinking water. They vary however in the application and operation. Sludge Digestion The primary sludge generated from the primary clarifier on averages represents approximately 40% to 60% of the suspended material in the wastewater. This equates to approximately 25% to 35% of the BOD in the wastewater. Anaerobic digestion produces considerably less biomass than what is produced under aerobic digestion. Biomass is produced when the number of microbial organisms increases (e.g., the organic constituents inherent in the sludge are consumed by a growing bacterial population and are thus converted into an increasing quantity of bacterial cell mass called biomass). Microbial digestion under anaerobic conditions often will consume 50% to 60% of the sludge while converting only about 10% of that consumed matter into biomass. In general, facultative and anaerobic bacteria capable of living under low oxygenated conditions convert the digestible organic content into volatile organic acids, which are then completely metabolized by a different group of bacteria into methane and carbon dioxide

- 8. methane and carbon dioxide. The stability of the anaerobic process is quite fragile. A balance must be maintained amongst several microbial populations. The hydrolysis and fermentation phases of the digestion are accomplished by the most tolerant group of microorganisms able to survive in the broadest range of environmental conditions. Overfeeding of this group can quickly lead to an increase of volatile fatty acids within the digester which can reduce the pH and harm the acetogens and methanogens and stall the digestion process. The anaerobic digested sludge is held in the tank from 10 days to 90 days, depending on the specific operation of the unit. The overall goal is to reduce the total volume of biosolids and to produce a stable biosolid material that can then be disposed of via burial, landfill, incineration, or land application. Under proper operating conditions the concentration of methane in the biogas generated by the anaerobic digester may be high enough to be used as a viable biogas fuel to supplement the power requirements of the plant. TABLE OF CONTENTS 1 Wastewater Treatment NAVIGATION Home Site pages Current course Water and Health Course 3 Participants General Introduction Treatment Technologies Source Water Protection Point of Use Treatments Drinking Water Treatments Drinking Water - Advanced Technologies On-Site Wastewater Treatment Constructed Wetlands - Wastewater Conventional Wastewater Treatment Conventional Wastewater Treatment Wastewater - Advanced Technologies References Courses ADMINISTRATION

- 9. Book administration Print book Print this chapter You are currently using guest access (Log in) Water&Health3