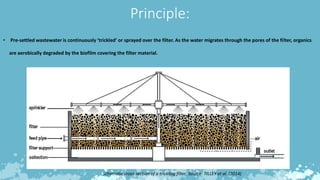

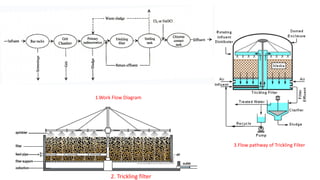

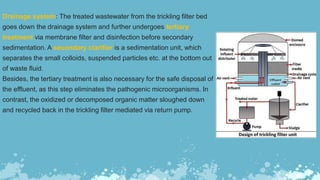

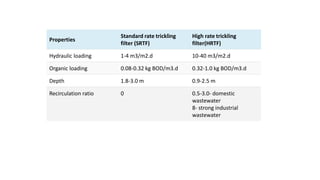

The document describes the trickling filter process, a wastewater treatment system that uses a fixed-bed biological reactor to degrade organic and inorganic waste. It outlines the operational stages, types of trickling filters, advantages, and disadvantages of the system. The trickling filter serves as a secondary treatment after primary settling, effectively removing 75-90% of biological oxygen demand (BOD) and allowing for safer effluent disposal.