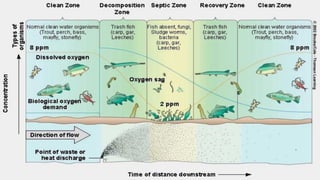

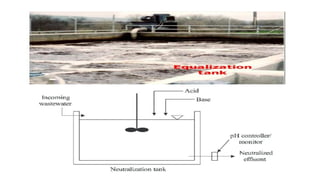

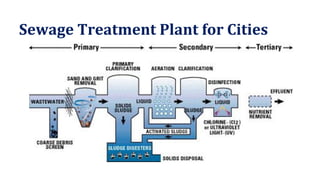

- Wastewater treatment involves physical, chemical, and biological processes to remove contaminants from water.

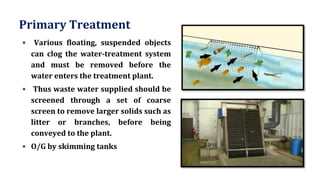

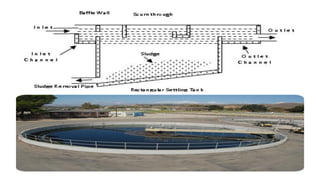

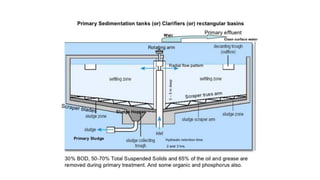

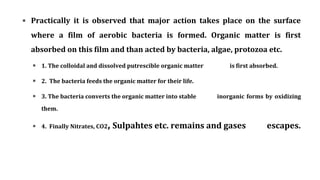

- Primary treatment uses screens to remove floating solids and sedimentation to remove suspended solids. Secondary treatment uses biological processes like activated sludge or trickling filters to further break down organic matter.

- Tertiary treatment may include disinfection through chlorination or other methods to kill pathogens before discharge or reuse of treated water. Proper treatment is necessary to prevent pollution of water resources.