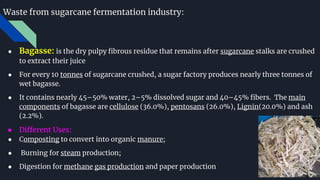

Fermentation industries produce various wastes that require management. Waste from cereal fermentation includes distillers grains, a nutritious feed byproduct. Sugarcane fermentation generates bagasse, used as fuel, compost, and in paper/board production. Bagasse can also be anaerobically digested to produce biogas. Fruit fermentation waste is pomace, used as animal feed and to extract compounds like polyphenols. Proper management of these wastes supports the sustainability of fermentation industries.