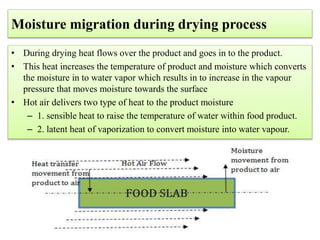

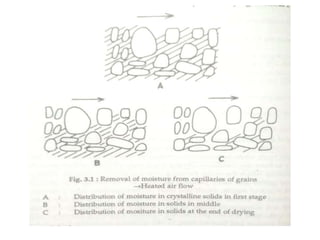

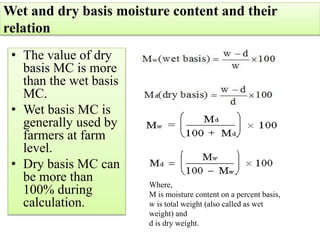

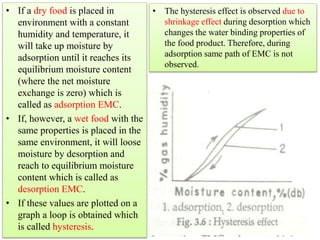

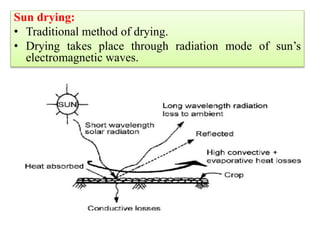

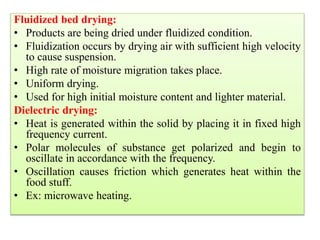

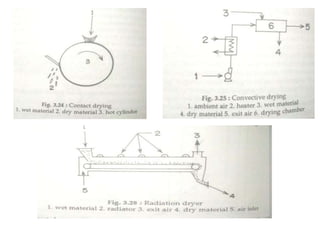

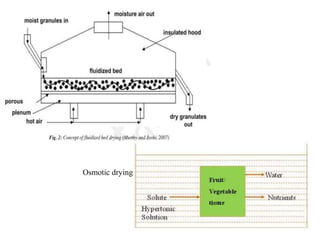

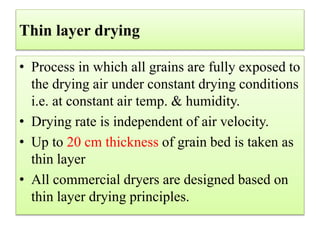

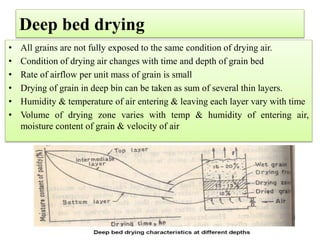

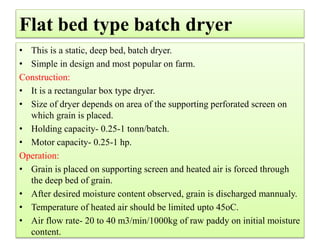

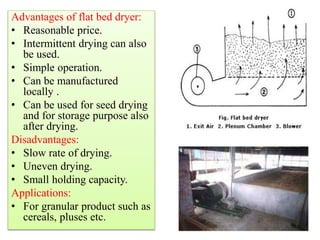

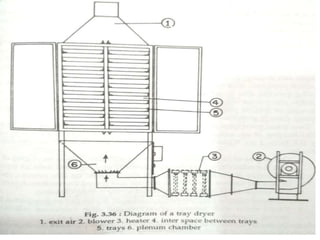

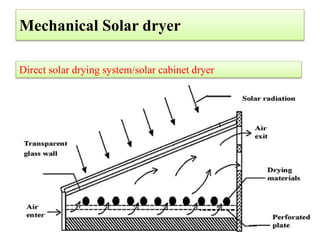

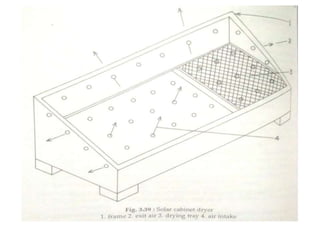

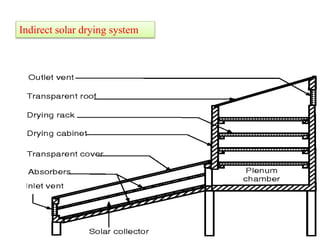

The document discusses the drying process for grains, emphasizing its importance in food preservation and safe storage. It covers various methods of drying, moisture content determination, and types of dryers, highlighting both traditional and modern techniques. The conclusion stresses the critical role of drying in maintaining food security by preventing deterioration through optimal moisture control.