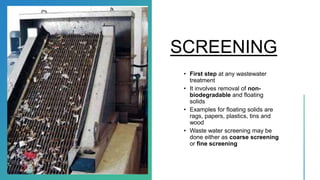

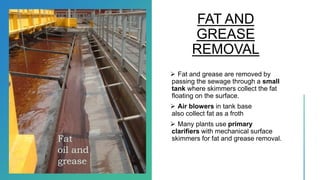

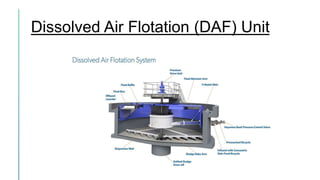

There are six physical methods used to treat wastewater: screening, grit chambers, fat and grease removal, flotation, equalization basins, and clarifiers. Screening removes large solids, grit chambers remove sand and debris, fat and grease removal uses skimmers, flotation removes oils and greases using dissolved air, equalization basins level flows, and clarifiers remove solids through sedimentation.