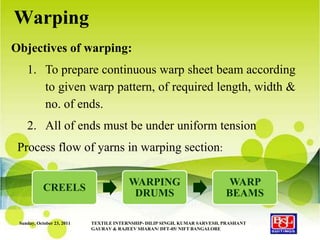

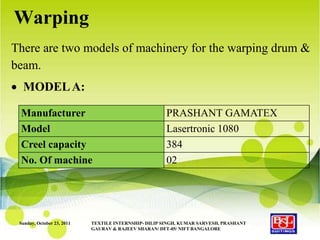

The document discusses the objectives and process of warping. It describes two models of warping machinery - Model A and Model B from Prashant Gamatex. Both models have a creel capacity of 384 and can warp yarns at speeds up to 800 meters/minute. The document also provides technical specifications for the warping creel and production time estimates for warping drums and transferring yarns to beams. A sample warper for silk is also described.