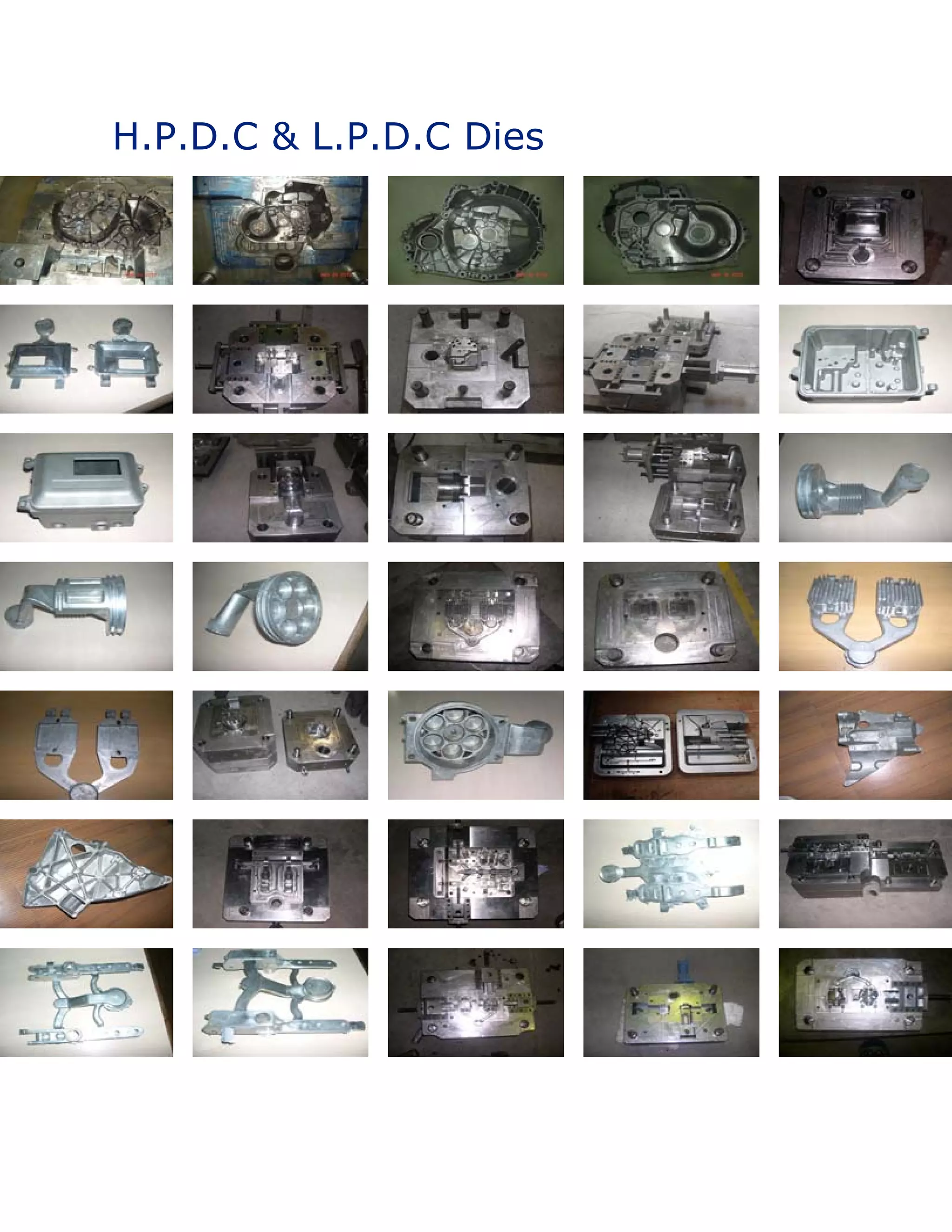

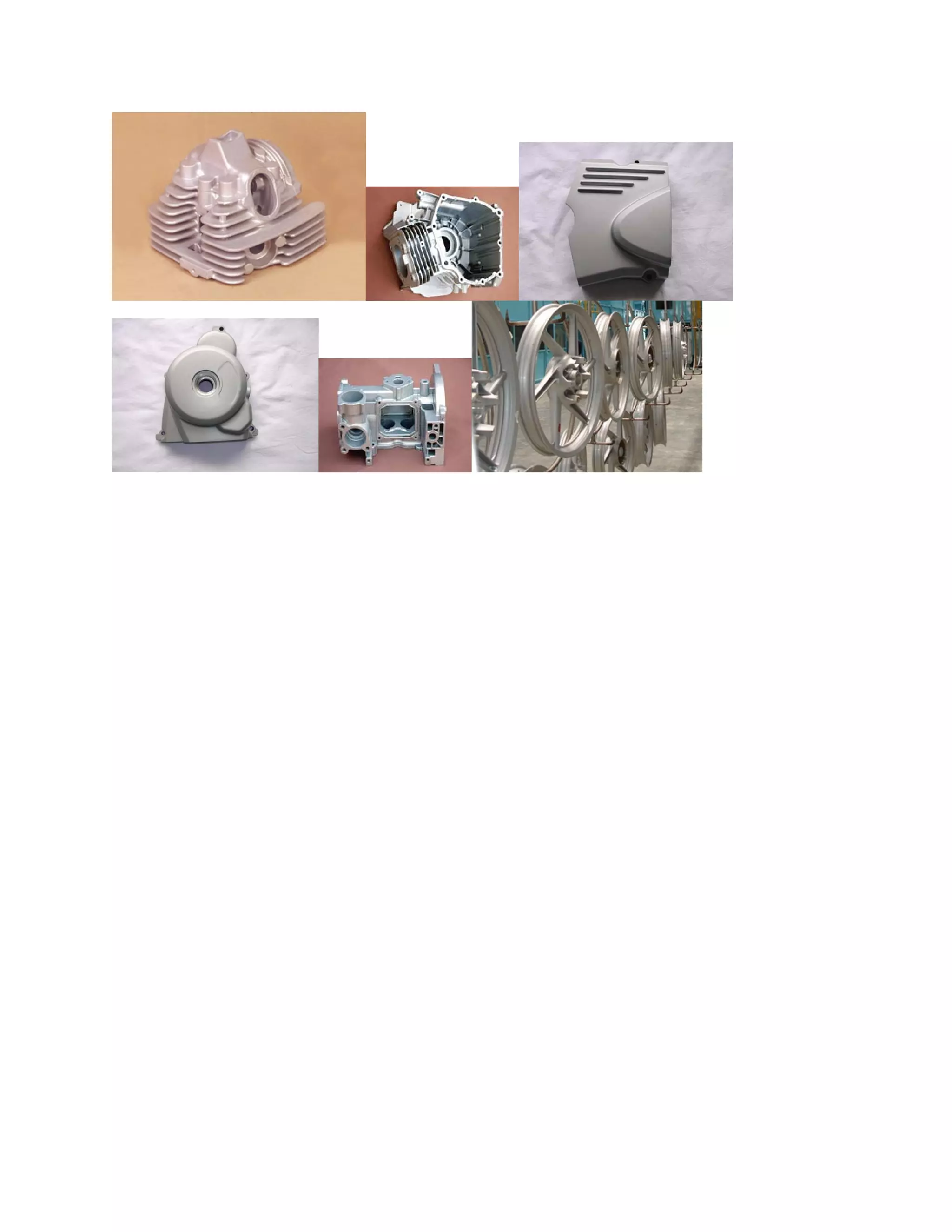

The factory was built in 2004 and is located in Pune, Maharashtra, India. It covers 6,000 square feet and has over 35 staff members, with technical staff and managers making up 60% of employees. The factory specializes in die designing, manufacturing, and machining of aluminum and zinc alloy castings up to 5 kilograms for automotive, motorcycle, household appliance, and other industries. It has CNC lathes and machining centers for post-processing and produces dies, die castings, and associated tools.