1. The document describes a conversion kit that has been designed to upgrade existing shuttle looms to more efficient rapier looms.

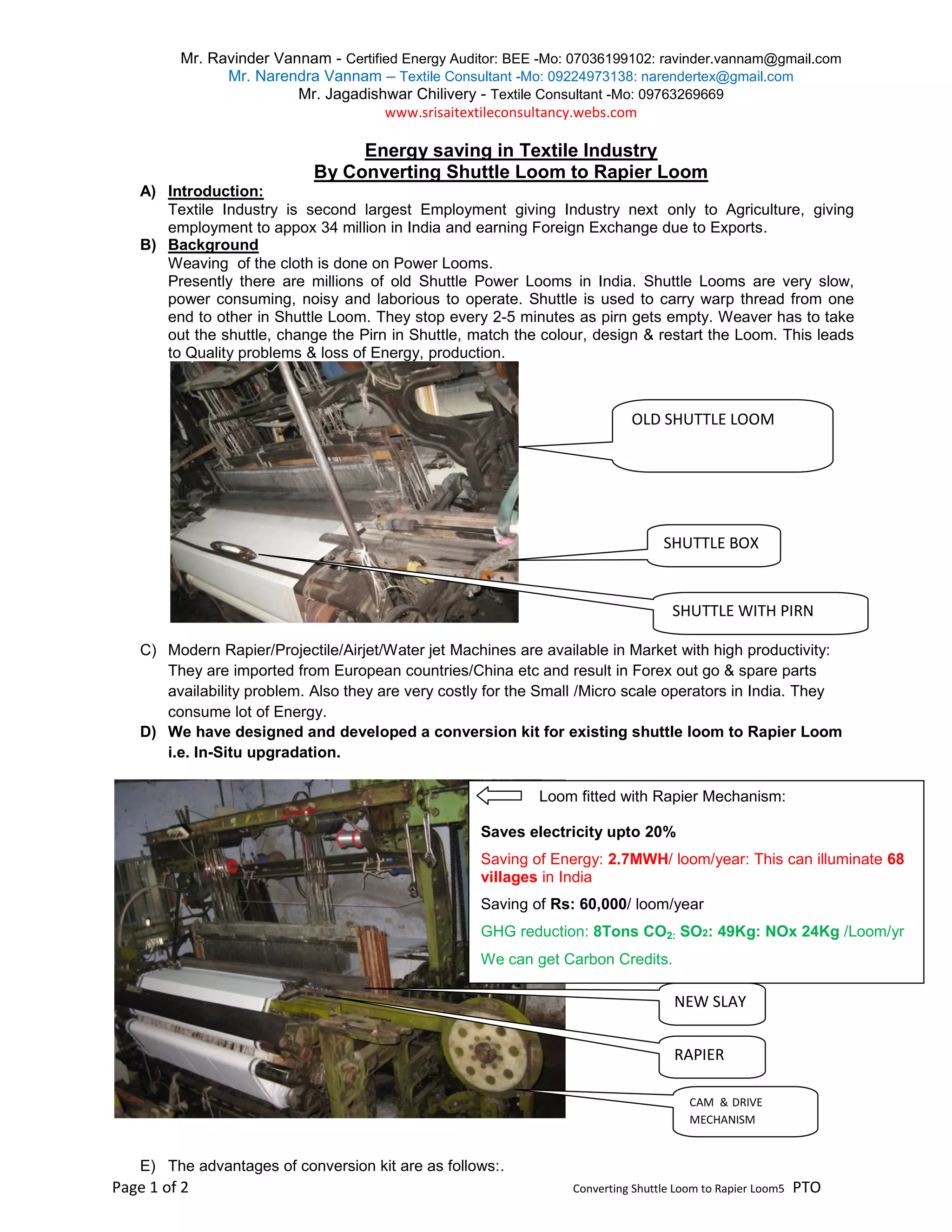

2. The conversion kit saves up to 20% on electricity usage and 2.7 MWh of energy per loom per year.

3. Implementing the conversion kit on 5 lakh looms could save Rs. 675 crore per year in electricity costs and reduce carbon emissions by 4 million tons of CO2, 24,000 tons of SO2, and 12,000 tons of NOx annually.

4. The conversion kit has been successfully trialled and implemented on looms in several Indian states.