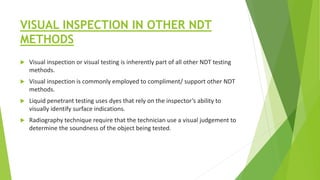

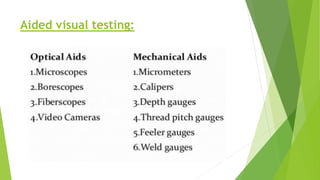

Visual inspection is a method of examining assets using the naked eye to identify non-conformities, often supporting other non-destructive testing (NDT) methods. It can include both unaided and aided visual techniques and is applied in various applications, notably in weld and hydraulic system inspections. While advantageous for its simplicity and speed, visual inspection has limitations such as being restricted to surface flaws and dependent on the inspector's skill.