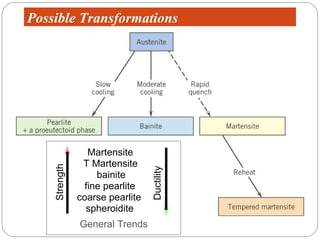

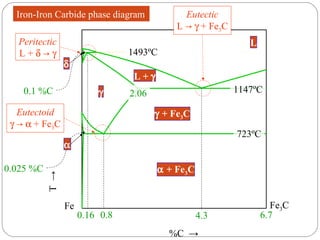

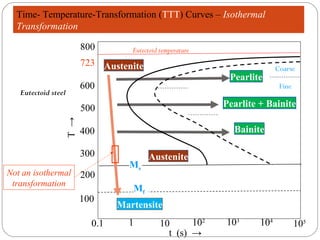

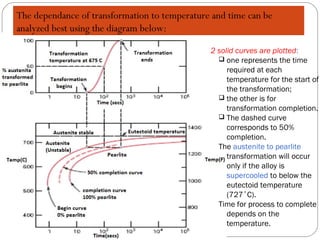

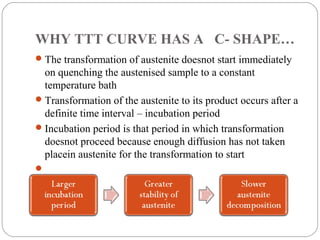

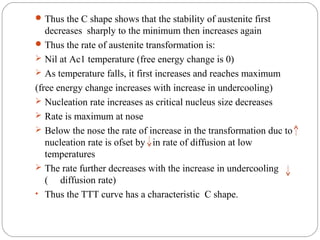

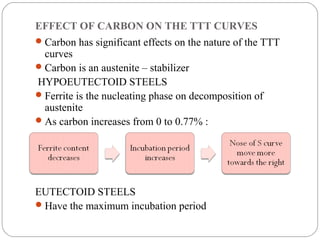

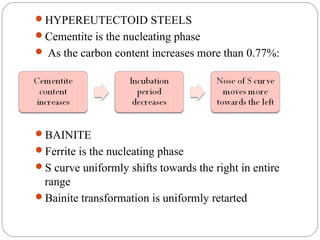

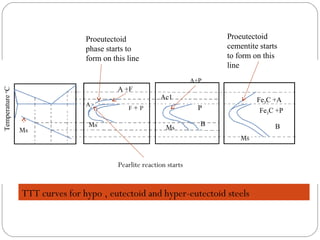

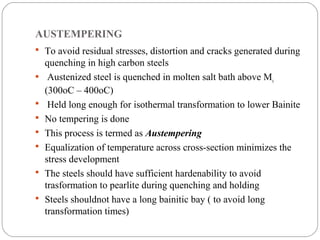

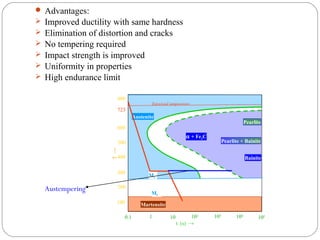

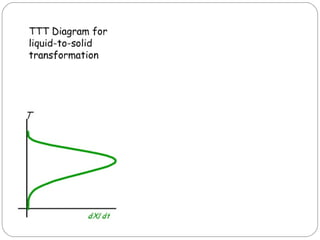

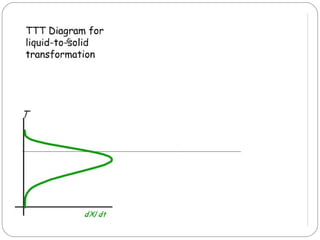

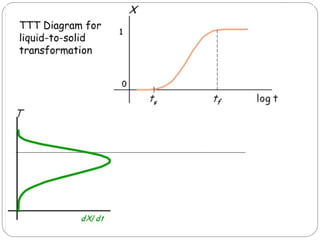

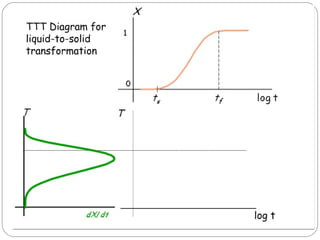

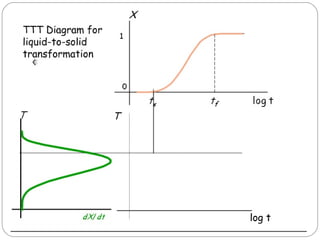

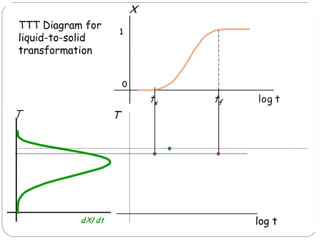

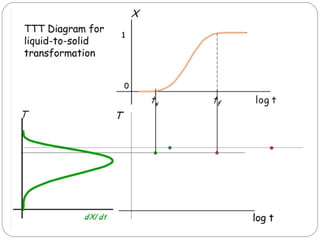

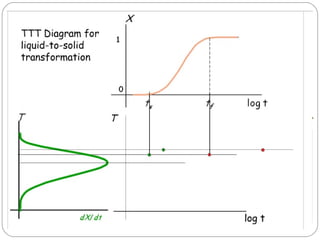

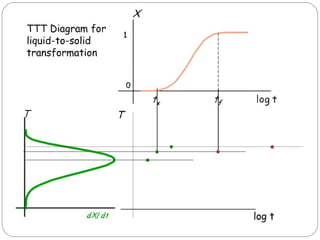

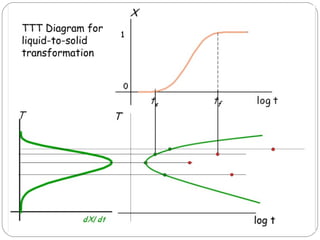

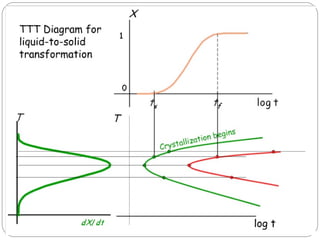

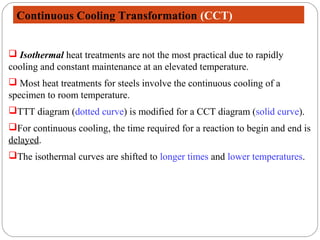

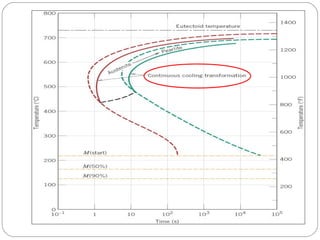

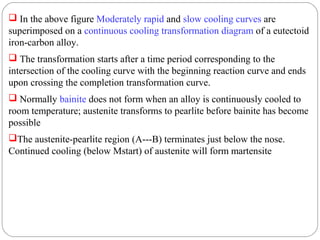

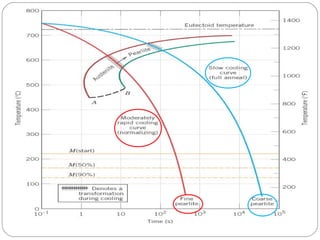

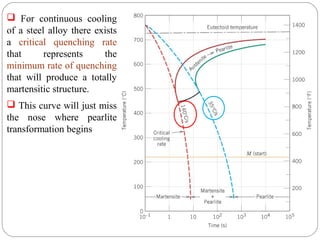

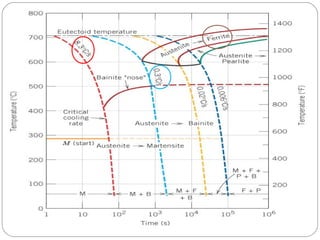

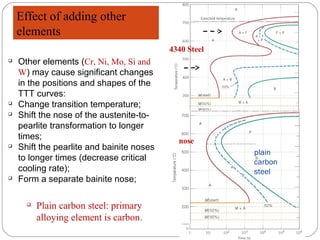

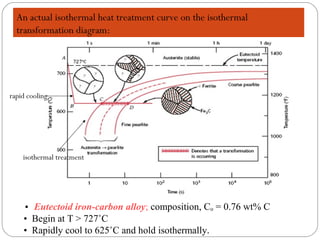

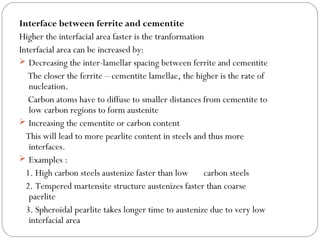

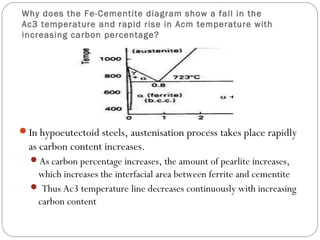

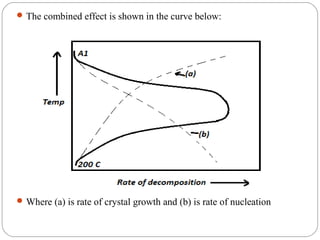

The document discusses phase transformations in materials and heat treatments. It explains that phase transformations can be used to vary the mechanical properties of alloys between 700-2000 MPa depending on the heat treatment. Time-temperature-transformation (TTT) diagrams are used to determine when phase transformations start and end during isothermal heat treatments. TTT diagrams have a characteristic C-shape due to the competing factors of nucleation and diffusion rates during transformations. The position and shape of TTT curves are affected by variables like carbon content, alloying elements, and grain size of the material.

![Eutectoid Transformation rate ~ ΔT

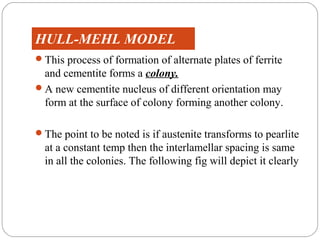

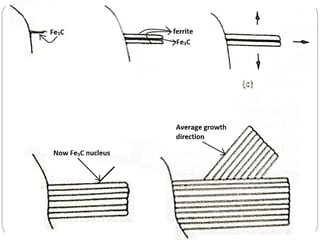

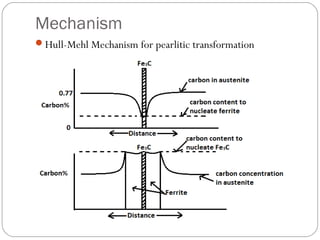

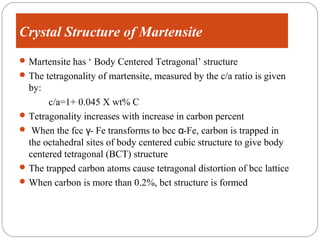

• Transformation of austenite to pearlite:

Diffusion of C

Austenite (γ) cementite (Fe3C) during transformation

grain α Ferrite (α)

boundary α γ α

γ α

α pearlite γ

α γ

growth α

α

direction

α

• For this transformation, 100

Carbon

diffusion

rate increases with ( ∆T) 600°C

(∆T larger)

% pearlite

[Teutectoid – T ]. 650°C

50

675°C

(∆T smaller)

0

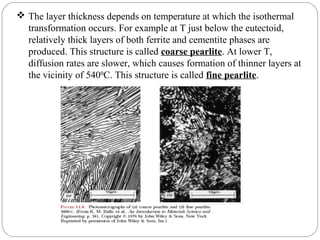

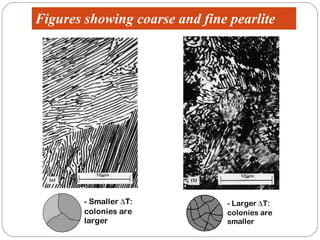

Coarse pearlite formed at higher temperatures – relatively soft

Fine pearlite formed at lower temperatures – relatively hard](https://image.slidesharecdn.com/phasetransformationedited-ppt1-130127140500-phpapp01/85/Phase-transformation-edited-ppt1-19-320.jpg)

![Transformation rate ~ ΔT

• Transformation of austenite to pearlite:

Diffusion of C

Austenite (γ) cementite (Fe3C) during transformation

grain α Ferrite (α)

boundary α γ α

γ α

α pearlite γ

α γ

growth α

α

direction

α

• For this transformation, 100

Carbon

diffusion

rate increases with ( ∆T) 600°C

(∆T larger)

% pearlite

[Teutectoid – T ]. 650°C

50

675°C

(∆T smaller)

0

Coarse pearlite formed at higher temperatures – relatively soft

Fine pearlite formed at lower temperatures – relatively hard](https://image.slidesharecdn.com/phasetransformationedited-ppt1-130127140500-phpapp01/85/Phase-transformation-edited-ppt1-89-320.jpg)

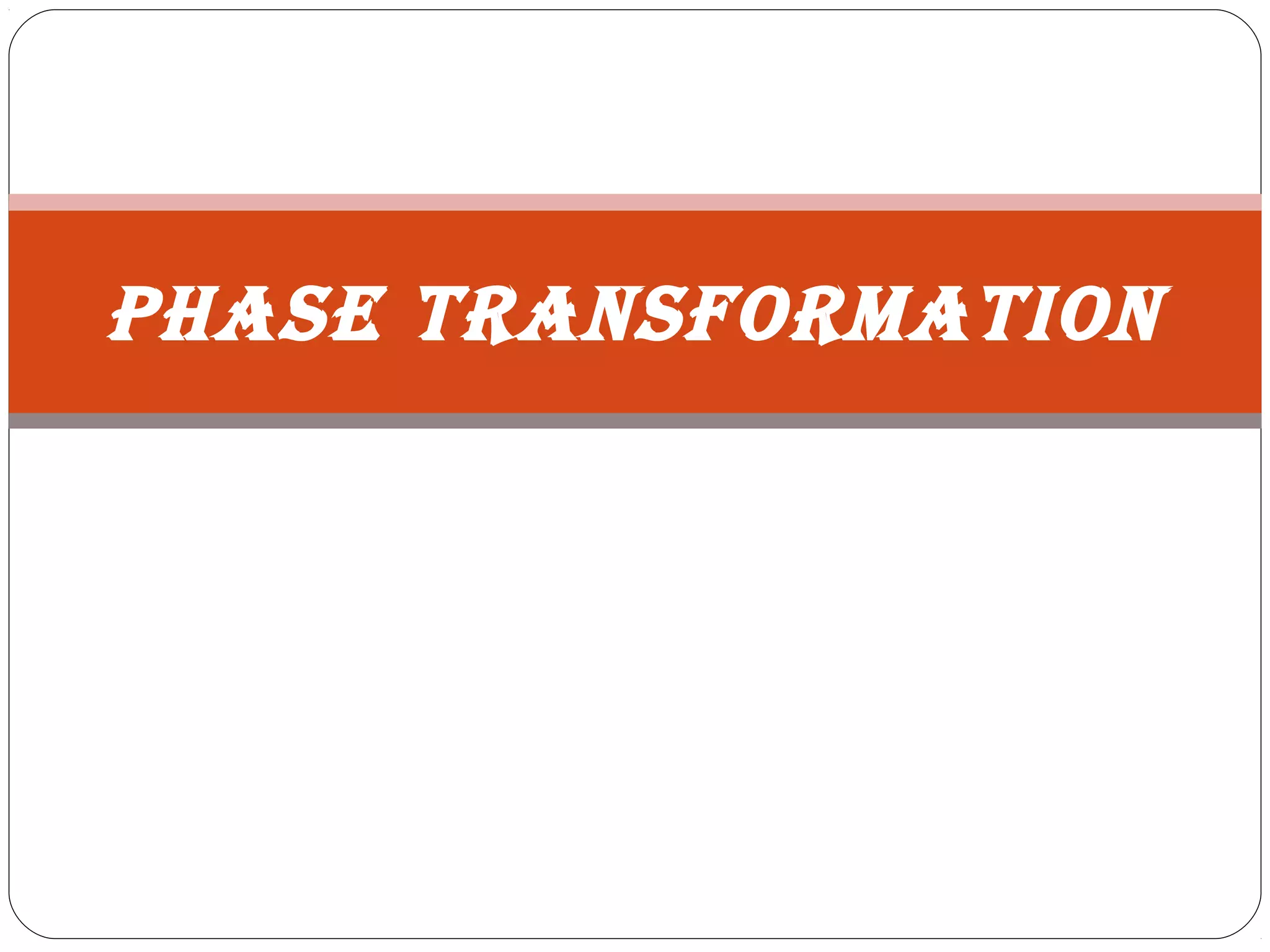

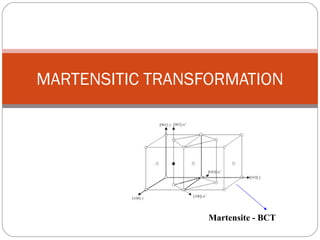

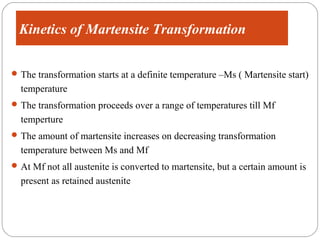

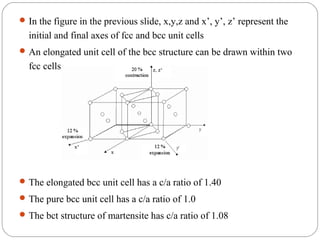

![ This model explains the transformation of martensite from

austenite with minimum movement of atoms

Thus carbon atoms are finally present only in the middle of

the edges along [001]axis and not in the middle of the edges

which represent the a-axis](https://image.slidesharecdn.com/phasetransformationedited-ppt1-130127140500-phpapp01/85/Phase-transformation-edited-ppt1-163-320.jpg)