Embed presentation

Downloaded 38 times

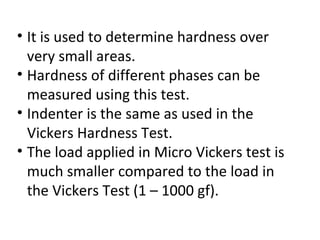

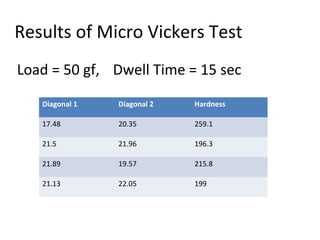

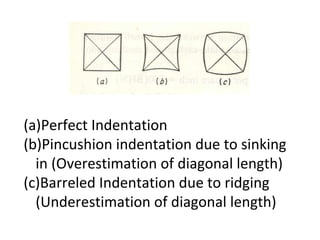

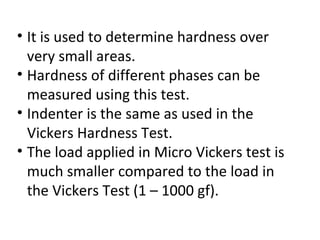

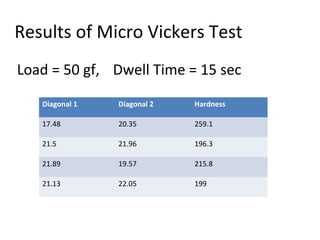

The document summarizes the results of a micro Vickers hardness test. The test was performed on samples with a load of 50 gf and dwell time of 15 seconds. The test measured the hardness of different phases using a small indenter, obtaining values between 196.3-259.1. The main drawback is needing to optically measure the small indents, requiring a polished surface.