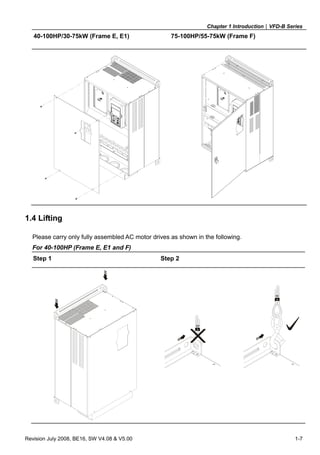

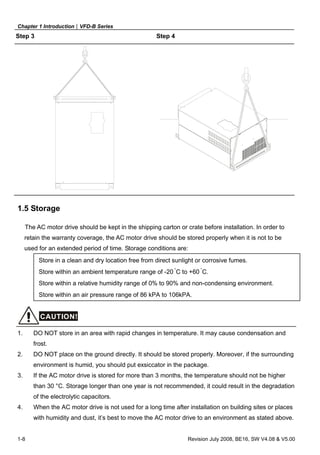

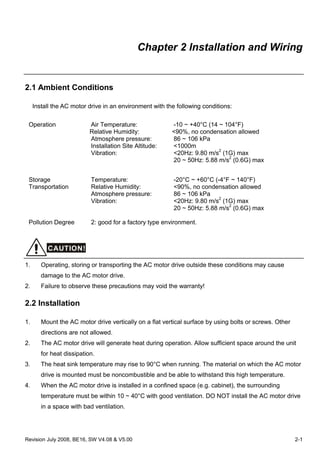

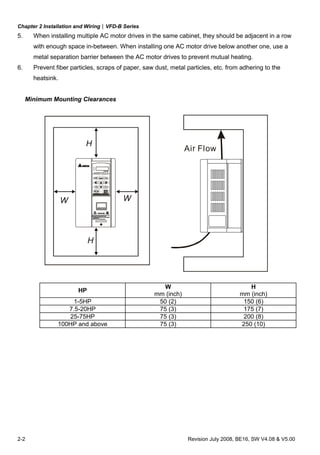

This document provides instructions for installing and operating a DELTA VFD-B Series AC motor drive. It describes receiving the product and inspecting for damage or incorrect parts. Safety guidelines are outlined that must be followed before powering and wiring the drive. Only qualified personnel should install, start-up and maintain the drive. The document provides dimensions and specifications for the drive frames and information on preparing the drive for installation such as removing the keypad and front cover. It also describes proper lifting of larger drives and storage conditions.

![Chapter 2 Installation and Wiring|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 2-3

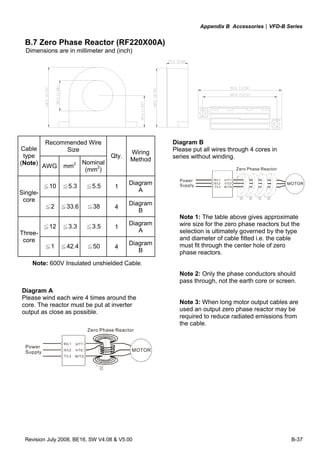

2.3 Dimensions

(Dimensions are in millimeter and [inch])

Frame A: VFD007B23A/43A/53A

5.5[0.22]108.0 [4.25]

118.0 [4.65]

173.0[6.81]

185.0[7.28]

5.5[0.22]

R2.75[0.11]

145.0 [5.71]

8.7[0.34]

22.0[ 0.87]

28.0[ 1.10](2X)](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-20-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

2-4 Revision July 2008, BE16, SW V4.08 & V5.00

Frame A1: VFD007B21A, VFD015B21A/23A/43A/53A

5.5[0.22]

R2.75[0.11]

5.5[0.22]

185.0[7.28]

173.0[6.81]

160.0 [6.30]118.0 [4.65]

108.0 [4.25]

8.7[0.34]

28.0[ 1.10](2X)

22.0[ 0.87]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-21-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 2-5

Frame A2: VFD015B21B/23B, VFD022B23B/43B/53A

5.5[0.22]

R2.75[0.11]

28.0[ 1.10](2X)

22.0[ 0.87]

8.7[0.34]

145.0 [5.71]118.0 [4.65]

108.0 [4.25] 5.5[0.22]

185.0[7.28]

173.0[6.81]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-22-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

2-6 Revision July 2008, BE16, SW V4.08 & V5.00

Frame B: VFD022B21A, VFD037B23A/43A/53A

11.3[0.44]

6.5[

0.26]

22.0[

0.87](2X)

28.0[

1.10](2X)

R3.25[R0.13]

6.5[0.26]

260.0[10.24]

UNIT : mm(inch)

135.0 [5.32] 160.2 [6.31]

244.3[9.63]

150.0 [5.91]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-23-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 2-7

Frame C: VFD055B23A/43A/53A, VFD075B23A/43A/53A, VFD110B23A/43A/53A

200.0 [7.88]

323.0[12.72]

185.6 [7.31]

303.0[11.93]

R3.5

[R

0.14]

7.0 [0.28]

13.5[0.53]

183.2 [7.22]

7.0[

0.28]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-24-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

2-8 Revision July 2008, BE16, SW V4.08 & V5.00

Frame D: VFD150B23A/43A/53A, VFD185B23A/43A/53A, VFD220B23A/43A/53A

13.0[0.51]

10.0 [0.39]

R5.0[R0.20]

403.8[15.90]

384.0[15.12]

42.0[ 1.65](2X)

250.0 [9.84]

226.0 [8.90]

28.0[

1.10]

205.4 [8.08]

10.0 [ 0.39]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-25-320.jpg)

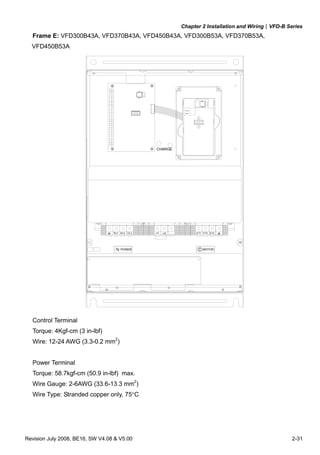

![Chapter 2 Installation and Wiring|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 2-9

Frame E: VFD300B43A/53A, VFD370B43A/53A, VFD450B43A/53A

335.0 [13.19]

370.0 [14.57] 260.0 [10.24]

589.0[23.19]

560.0[22.05]

18.0 [0.71]

132.5 [5.22]

R6.5[0.25]

13.0[0.51]

21.0[0.83]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-26-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

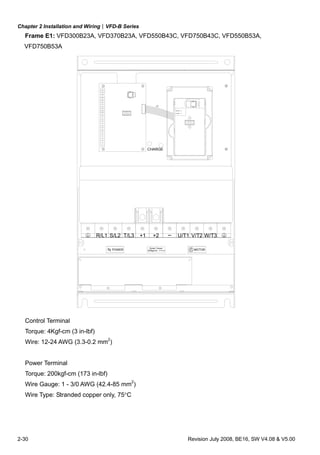

2-10 Revision July 2008, BE16, SW V4.08 & V5.00

Frame E1: VFD300B23A, VFD370B23A, VFD550B43C/53A, VFD750B43C/53A

132.5 [5.22]

18.0 [0.71]21.0[0.83]

335.0 [13.19]

370.0 [14.57] 260.0 [10.24]

589.0[23.19]

560.0[22.05]

R6.5[0.25]

13.0[0.51]

595.0[23.43]](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-27-320.jpg)

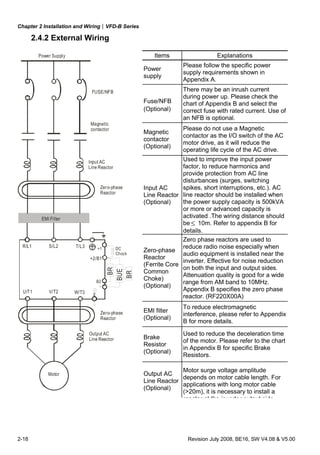

![Chapter 2 Installation and Wiring|VFD-B Series

2-20 Revision July 2008, BE16, SW V4.08 & V5.00

DO NOT connect phase-compensation capacitors or surge absorbers at the output terminals

of AC motor drives.

With long motor cables, high capacitive switching current peaks can cause over-current, high

leakage current or lower current readout accuracy. To prevent this, the motor cable should

be less than 20m for 3.7kW models and below. And the cable should be less than 50m for

5.5kW models and above. For longer motor cables use an AC output reactor.

Use a well-insulated motor, suitable for inverter operation.

Terminals [+1, +2] for connecting DC reactor

+1

Jumper

DC reactor

To improve the power factor and reduce harmonics, connect a DC reactor between terminals

[+1, +2]. Please remove the jumper before connecting the DC reactor.

NOTE Models of 15kW and above have a built-in DC reactor.

Terminals [+2/B1, B2] for connecting brake resistor and terminals [+1, +2/B1] for connecting

external brake unit

B2

VFDB

-(minus sign)

BR

BR

Connect a brake resistor or brake unit in applications with frequent deceleration ramps, short

deceleration time, too low brake torque or requiring increased brake torque.

If the AC motor drive has a built-in brake chopper (all models of 11kW and below), connect

the external brake resistor to the terminals [+2/B1, B2].

Models of 15kW and above don’t have a built-in brake chopper. Please connect an external

optional brake unit (VFDB-series) and brake resistor. Refer to VFDB series user manual for

details.

Connect the terminals [+(P), -(N)] of the brake unit to the AC motor drive terminals

[+2(+2/B1), (-)]. The length of wiring should be less than 5m with twisted cable.

When not used, please leave the terminals [+2/B1, -] open.](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-37-320.jpg)

![Chapter 2 Installation and Wiring|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 2-21

WARNING!

1. Short-circuiting [B2] or [-] to [+2/B1] can damage the AC motor drive.

Grounding terminals ( )

Make sure that the leads are connected correctly and the AC drive is properly grounded.

(Ground resistance should not exceed 0.1Ω.)

Use ground leads that comply with local regulations and keep them as short as possible.

Multiple VFD-B units can be installed in one location. All the units should be grounded

directly to a common ground terminal, as shown in the figure below. Ensure there are no

ground loops.

goodexcellent not allowed

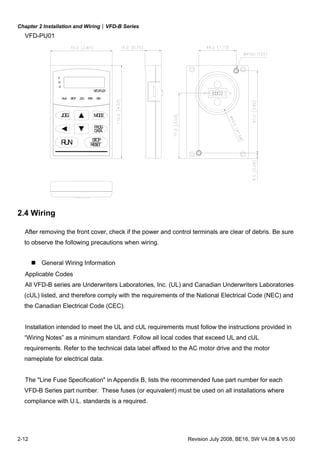

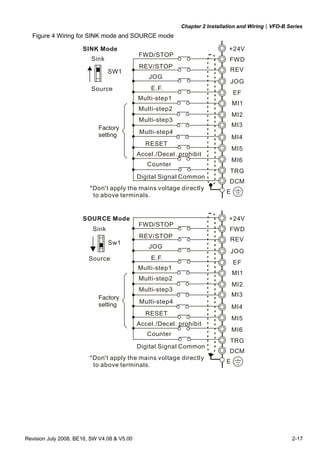

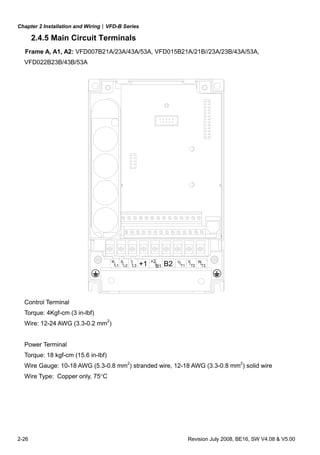

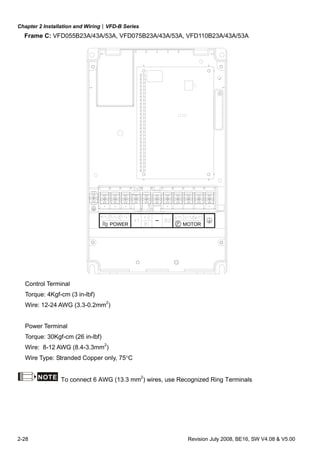

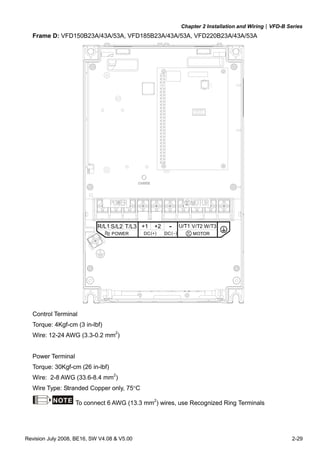

2.4.4 Control Terminals

Circuit diagram for digital inputs (SINK current 16mA.)

+24

SINK Mode

multi-input

terminal

Internal Circuit

DCM

+24V

Multi-Input

Terminal

DCM

Internal Circuit

SOURCE Mode

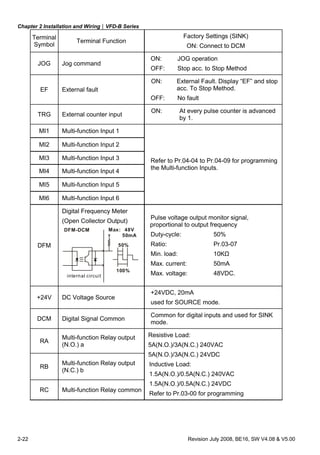

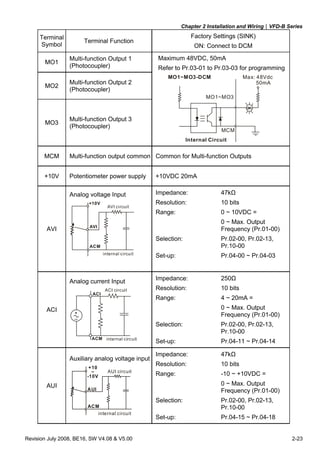

Terminal symbols and functions

Terminal

Symbol

Terminal Function

Factory Settings (SINK)

ON: Connect to DCM

FWD Forward-Stop command

ON: Run in FWD direction

OFF: Stop acc. to Stop Method

REV Reverse-Stop command

ON: Run in REV direction

OFF: Stop acc. to Stop Method](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-38-320.jpg)

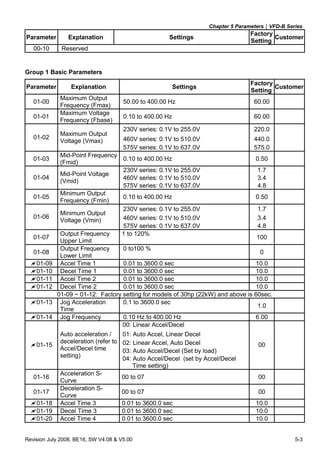

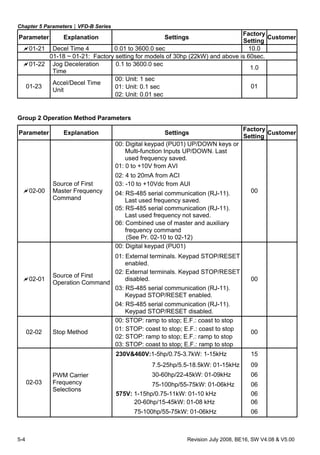

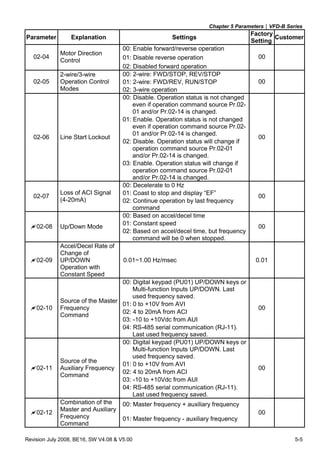

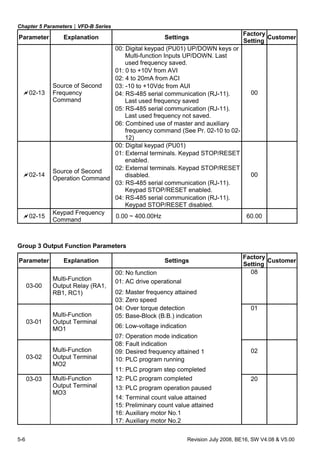

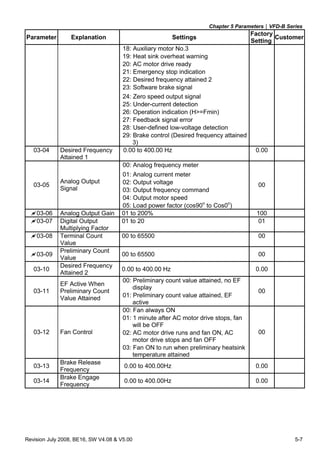

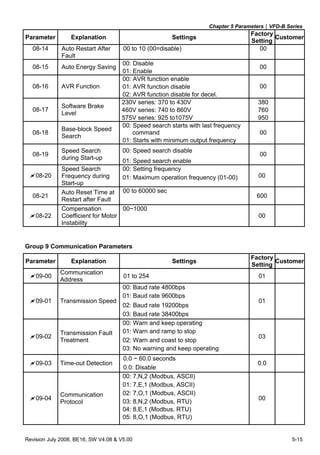

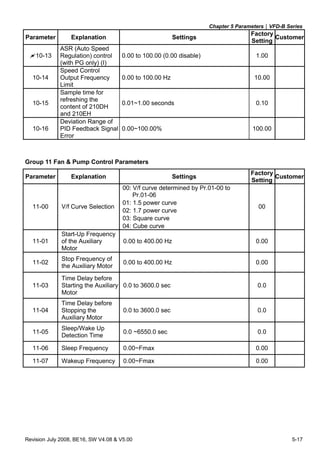

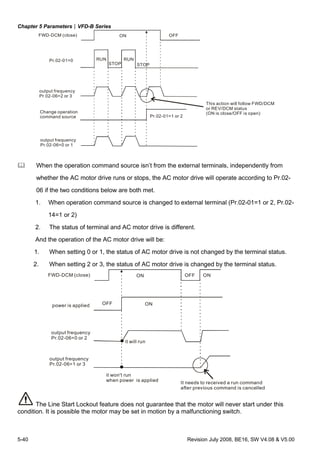

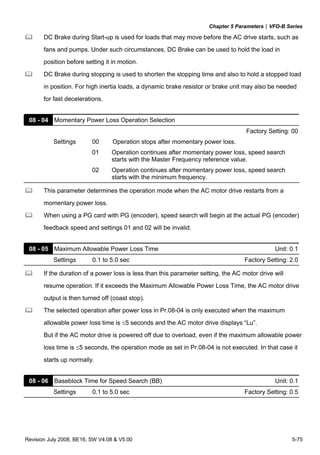

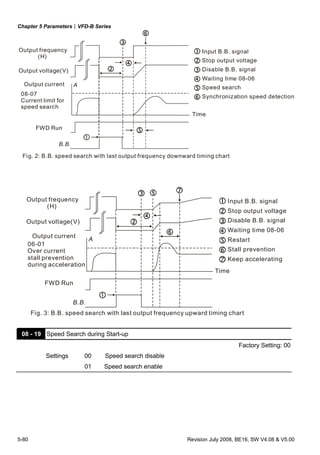

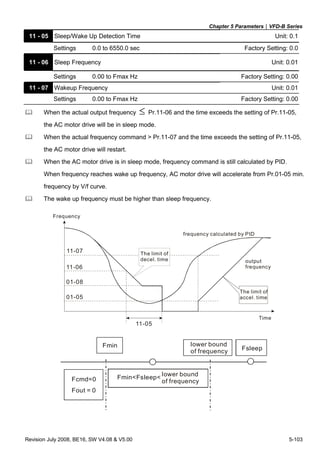

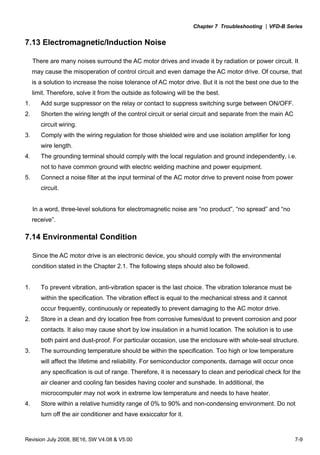

![Chapter 5 Parameters|VFD-B Series

5-94 Revision July 2008, BE16, SW V4.08 & V5.00

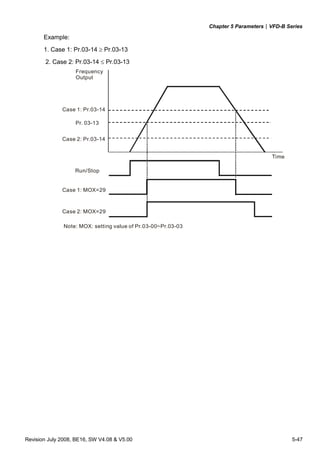

Exception

code Explanation

10

Communication time-out:

If Pr.09-03 is not equal to 0.0, Pr.09-02=00~02, and there is no

communication on the bus during the Time Out detection period (set

by Pr.09-03), “cE10” will be shown on the keypad.

3.7 Communication program of PC:

The following is a simple example of how to write a communication program for Modbus ASCII

mode on a PC by C language.

#include<stdio.h>

#include<dos.h>

#include<conio.h>

#include<process.h>

#define PORT 0x03F8 /* the address of COM1 */

/* the address offset value relative to COM1 */

#define THR 0x0000

#define RDR 0x0000

#define BRDL 0x0000

#define IER 0x0001

#define BRDH 0x0001

#define LCR 0x0003

#define MCR 0x0004

#define LSR 0x0005

#define MSR 0x0006

unsigned char rdat[60];

/* read 2 data from address 2102H of AC drive with address 1 */

unsigned char tdat[60]={':','0','1','0','3','2','1','0',’2', '0','0','0','2','D','7','r','n'};

void main(){

int i;

outportb(PORT+MCR,0x08); /* interrupt enable */

outportb(PORT+IER,0x01); /* interrupt as data in */

outportb(PORT+LCR,(inportb(PORT+LCR) | 0x80));

/* the BRDL/BRDH can be access as LCR.b7==1 */

outportb(PORT+BRDL,12); /* set baudrate=9600, 12=115200/9600*/

outportb(PORT+BRDH,0x00);

outportb(PORT+LCR,0x06); /* set protocol, <7,N,2>=06H, <7,E,1>=1AH, <7,O,1>=0AH,

<8,N,2>=07H, <8,E,1>=1BH, <8,O,1>=0BH */

for(i=0;i<=16;i++){](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-151-320.jpg)

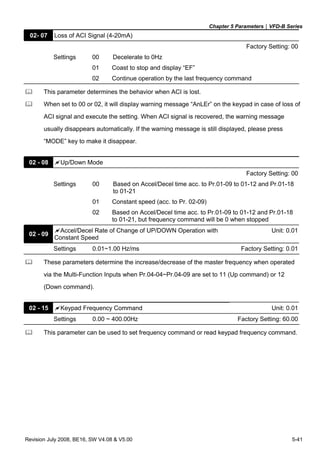

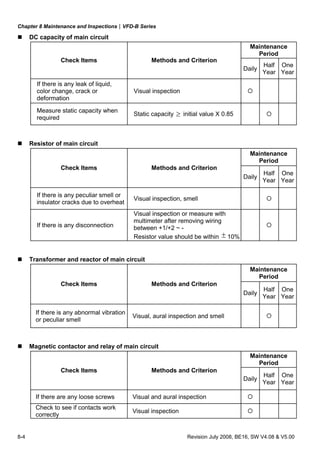

![Chapter 5 Parameters|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 5-95

while(!(inportb(PORT+LSR) & 0x20)); /* wait until THR empty */

outportb(PORT+THR,tdat[i]); /* send data to THR */ }

i=0;

while(!kbhit()){

if(inportb(PORT+LSR) & 0x01){ /* b0==1, read data ready */

rdat[i++]=inportb(PORT+RDR); /* read data form RDR */

} } }

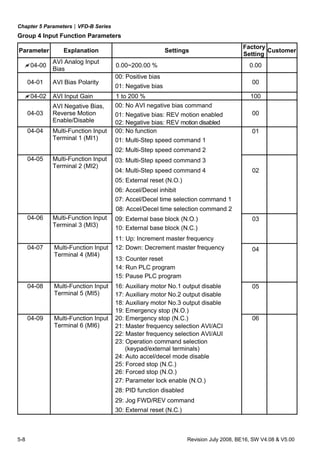

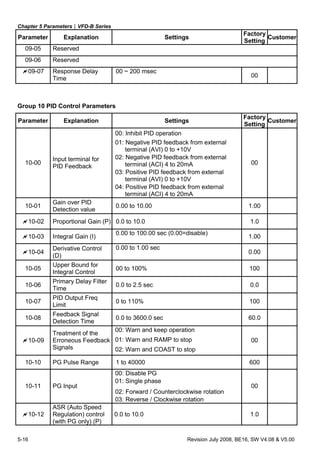

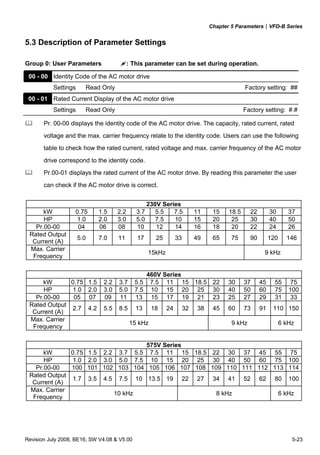

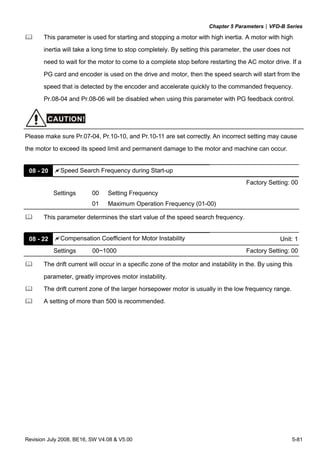

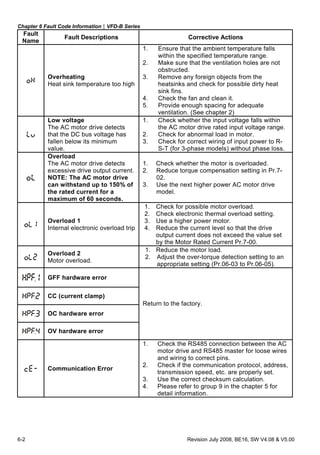

09 - 05 Reserved

09 - 06 Reserved

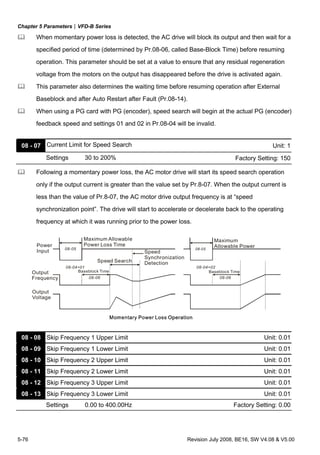

09 - 07 Response Delay Time Unit: 2

Settings 00 ~ 200 msec Factory Setting: 00

This parameter is the response delay time after AC drive receives communication command

as shown in the following.

RS485 BUS

PC or PLC command

Handling time

of AC drive

Response Delay Time

Response Message of AC Drive

Max.: 6msec

Pr.09-07

* This parameter is only for firmware version 4.01 and higher.](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-152-320.jpg)

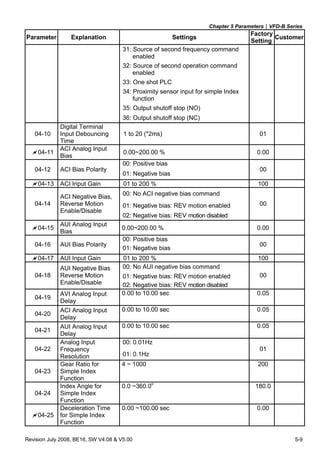

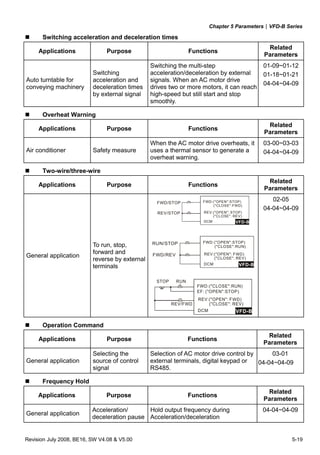

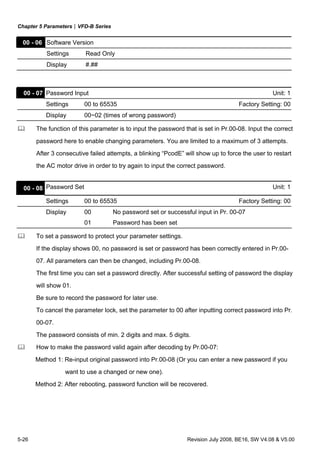

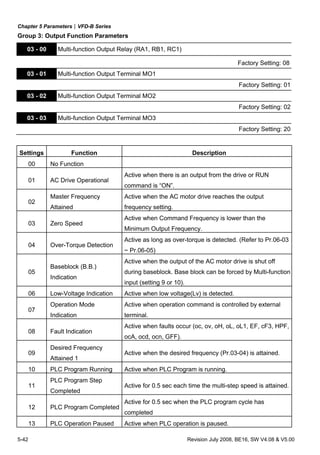

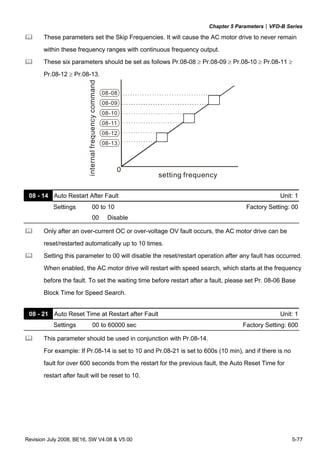

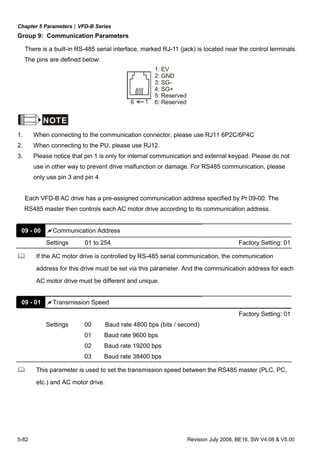

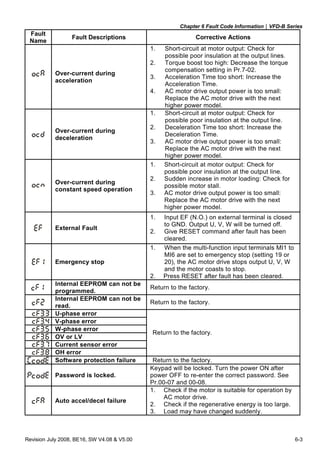

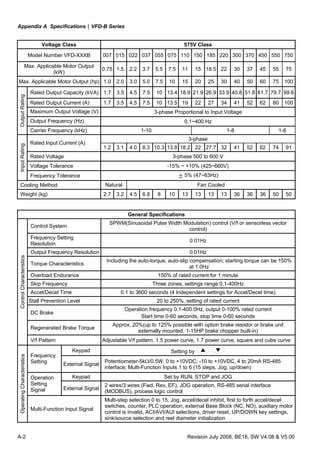

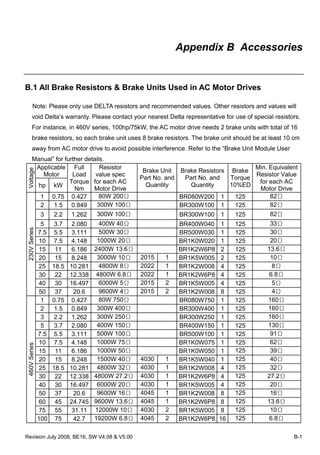

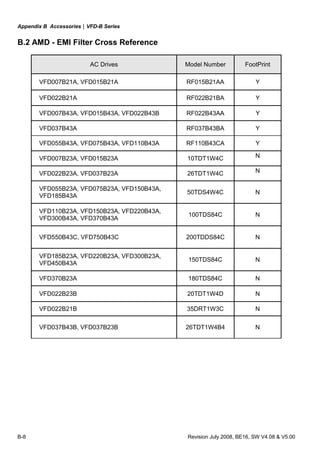

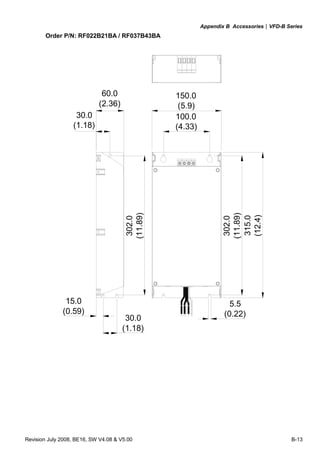

![Appendix B Accessories|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 B-7

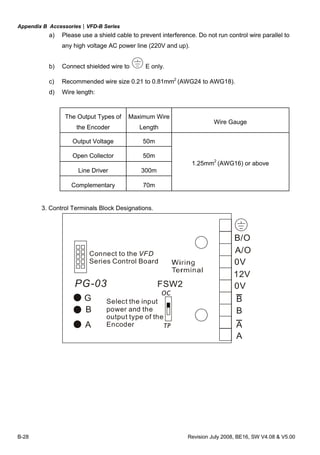

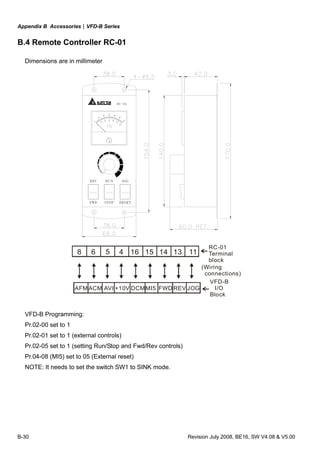

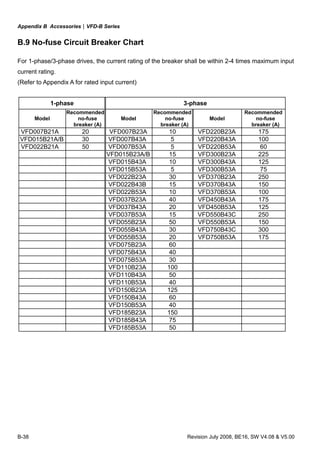

B.1.3 Dimensions for Brake Unit

(Dimensions are in millimeter[inch])

80.0 [3.15]

121.0 [4.76]

189.5[7.46]

200.0[7.87]

130.0 [5.12]

R3.3 [R0.13]

ACT.

YELLOW

CHARGE

GREEN

ERR.

RED](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-194-320.jpg)

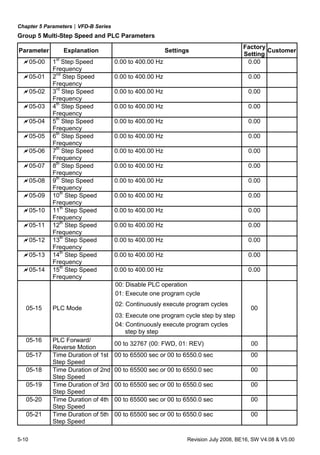

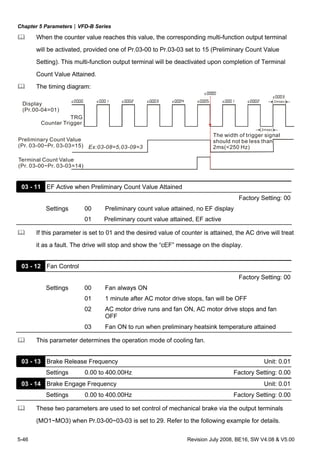

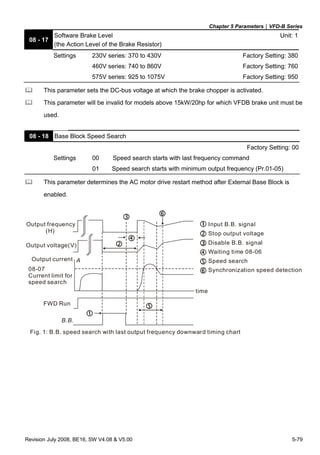

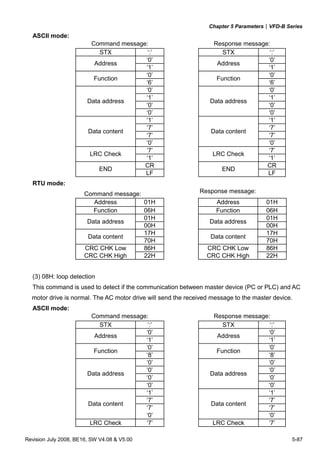

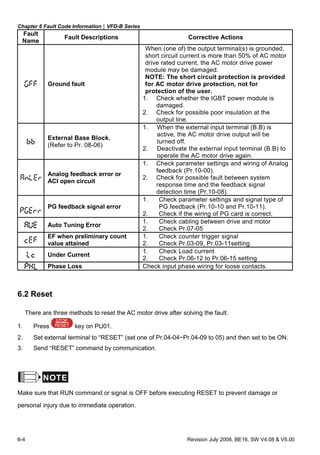

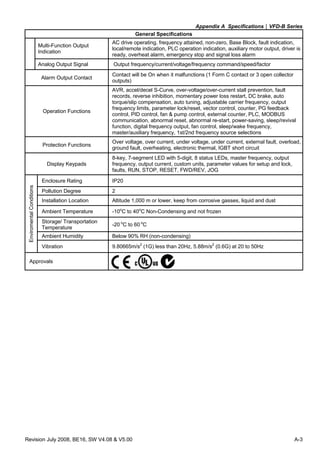

![Appendix C How to Select the Right AC Motor Drive|VFD-B Series

C-2 Revision July 2008, BE16, SW V4.08 & V5.00

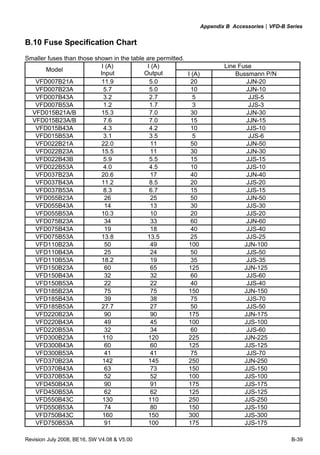

C.1 Capacity Formulas

1. When one AC motor drive operates one motor

The starting capacity should be less than 1.5x rated capacity of AC motor drive

The starting capacity=

)(_____5.1

375cos973

2

kVAdrivemotorACofcapacitythe

t

NGD

T

Nk

A

L ×≤⎟⎟

⎠

⎞

⎜⎜

⎝

⎛

×+

××

×

ϕη

2. When one AC motor drive operates more than one motor

2.1 The starting capacity should be less than the rated capacity of AC motor drive

Acceleration time ≦60 seconds

The starting capacity=

( )[ ] ( ) )(_____5.11

cos

111 kVAdrivemotorACofcapacitythek

n

n

Pknn

Nk

sCss

T

s

T ×≤+=+

×

×

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−−

ϕη

Acceleration time ≧60 seconds

The starting capacity=

( )[ ] ( ) )(_____1

cos

111 kVAdrivemotorACofcapacitythek

n

n

Pknn

Nk

sCss

T

s

T ≤+=+

×

×

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−−

ϕη

2.2 The current should be less than the rated current of AC motor drive(A)

Acceleration time ≦60 seconds

)(______5.111 AdrivemotorACofcurrentratedthekn

nIn SM

T

S

T ×≤++ ⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞⎜

⎝

⎛ −

Acceleration time ≧60 seconds

)(______11 AdrivemotorACofcurrentratedthekn

nIn SM

T

S

T ≤++ ⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞⎜

⎝

⎛ −

2.3 When it is running continuously](https://image.slidesharecdn.com/vfd-bmanualen-140613014201-phpapp01/85/Vfd-b-manual-en-233-320.jpg)