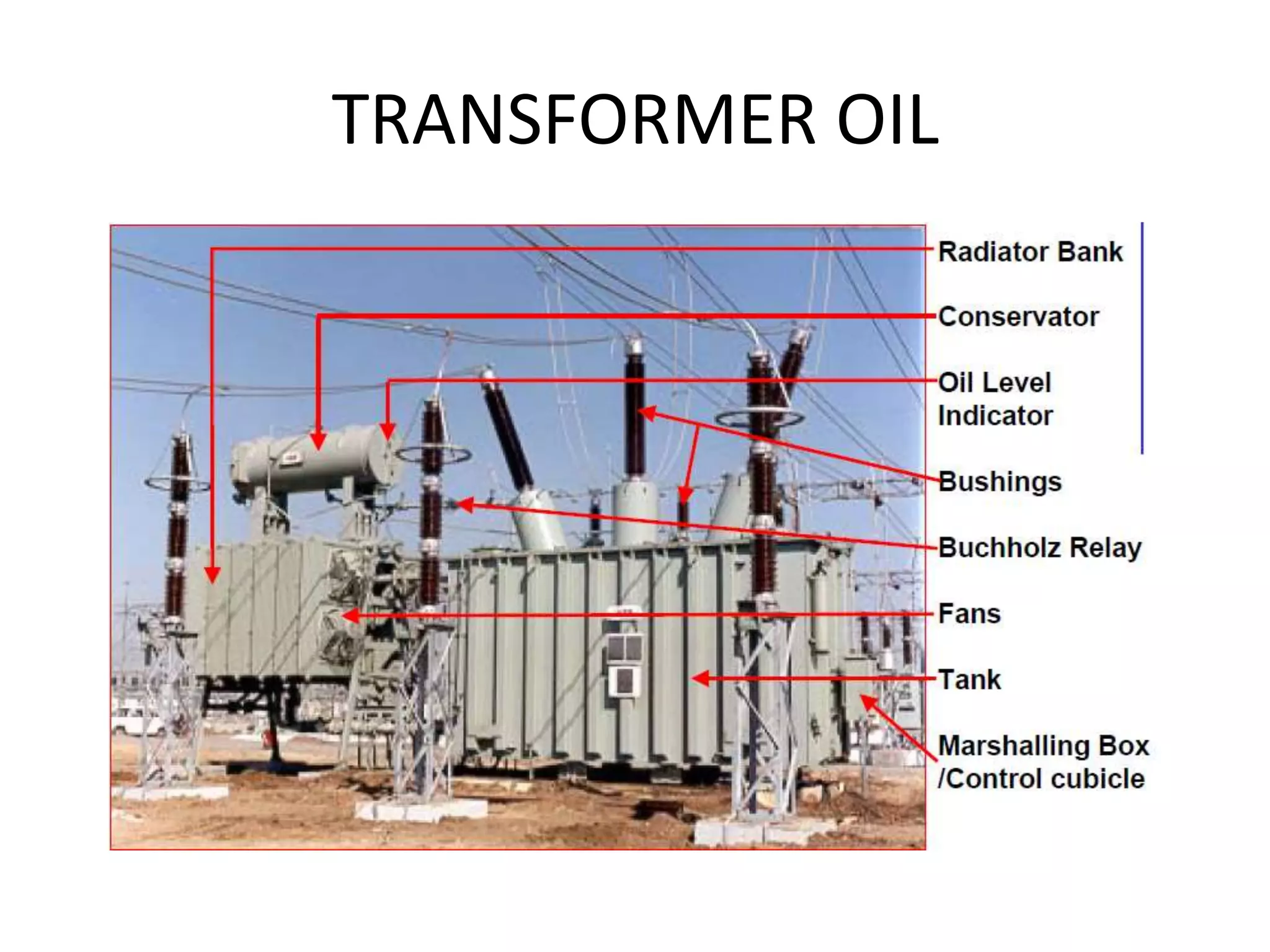

Transformer oil, derived from crude petroleum, serves as a liquid insulation and coolant for electrical power transformers, while also protecting components from moisture and oxidation. The breakdown voltage (bdv) is a key indicator of oil health, with a minimum safe value of 30 kV, requiring careful handling and storage to maintain its quality. Regular testing and monitoring of chemical and physical parameters, such as acidity and viscosity, are essential for ensuring the efficacy of transformer oil.