This document is a user manual for the PV Series Variable Speed Drive. It provides information on installation, wiring, parameter settings, troubleshooting and maintenance of the drive. Chapter 1 discusses important safety information for installing and using the drive properly. Chapter 2 provides product specifications and details about the drive's components, ratings and optional parts. The remaining chapters cover installation and wiring, operation procedures, parameter settings, troubleshooting and maintenance.

![Appendix 2 Communication Protocol 129

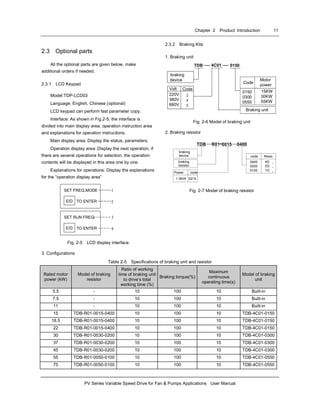

PV Series Variable Speed Drive for Fan & Pumps Applications User Manual

2) Example (Turbo C 2.0): Send the command of running the drive, stopping the drive and setting the frequency (need to

set F0.00 to 2, and set F0.03 to 2 first.)

#include <dos.h>

#include <bios.h>

#include <conio.h>

#include <stdio.h>

#define COM1 0 /*serial port 1*/

#define COM2 1 /*serial port 2*/

#define SET_COMPARA 0 /* To set the parameters of communication ports */

#define DEFAULT_BAUD 0xE3 /*8-N-1,9600bps*/

#define PORT_ADDR 0x3F8 /* Address of serial port is 13F8H*/

#define delaytime 100 /*100ms delay time */

char run_drive[20]="~010200000183r"; /* Command of running the drive */

char stop_drive[20]="~01020007018Ar"; /* Command of stopping the drive*/

void send_comd(char *sendstr,char *display_type); /* Send the command */

void checksum(char *sendstr,char result_sum[]); /*Calculate verify checksum*/

main()

{

char sum_of_cmd[5],buf[25]; /*store the string of 4-byte verify checksum */

char set_frequency[25]="010200010BB8"; /* set the running frequency at 30.00Hz */

bioscom(SET_COMPARA,DEFAULT_BAUD,COM1); /* set COM1, 8-N-1, 9600bps */

send_comd(run_drive,"HEX"); /* Send run command, display in HEX format */

printf("nPress anykey to set frequency to 30.00Hz ...");

while(!kbhit()); /* wait for pressing any key to input */

getchar(); /* get character */

checksum(set_frequency,sum_of_cmd); /* get the verify checksum of the sent command */

sprintf(buf,"~%s%sr",set_frequency,sum_of_cmd);

strcpy(set_frequency,buf); /* combine the sent frames */

send_comd(set_frequency,"HEX"); /* set to 30.00Hz, display in HEX format */

printf("nPress anykey to stop ...");

while(!kbhit()); /* wait for pressing any key to input */

send_comd(stop_drive,"ASCII"); /* Send stop command, display in ASCII format */

}

void send_comd(char *sendstr,char *display_type)

{

unsigned int i;

char buf[5]; /* used for character display */

printf("nSend(%s):",display_type);

for(i=0;i<strlen(sendstr);i++){ /* send the frame command */

outportb(PORT_ADDR,sendstr[i]);

delay(delaytime); /* The delay time should ensure the command can be

sent */](https://image.slidesharecdn.com/techpvseries-140613204721-phpapp02/85/Tech-pv-series-133-320.jpg)

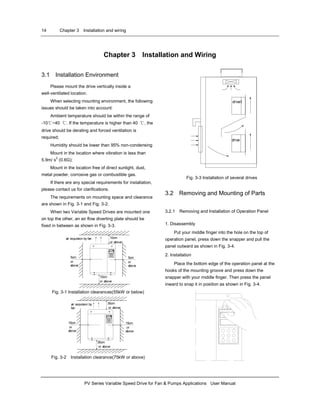

![130 Appendix 2 Communication Protocol

PV Series Variable Speed Drive for Fan & Pumps Applications User Manual

if(display_type[0]=='H') /* determine the display format */

{printf("%02x ",sendstr[i]);} /* display in HEX format */

else{printf("%c",sendstr[i]);} /* display in ASCII format */

}

}

void checksum(char *sendstr,char result_sum[])

{

unsigned int i,sum=0;

static char sum_string[5]; /* calculate the sum of all the characters */

for(i=0;i<strlen(sendstr);i++)sum+=(unsigned int)sendstr[i];

sprintf(sum_string,"%04x",sum);

for(i=0;i<4;i++)

result_sum[i]=toupper(sum_string[i]); /* convert into capital letters */

result_sum[i]=0x0; /* end of string */

} /*result_sum return ASCII string of Verify checksum */](https://image.slidesharecdn.com/techpvseries-140613204721-phpapp02/85/Tech-pv-series-134-320.jpg)