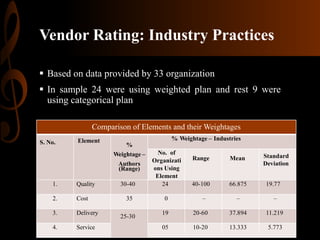

The document discusses the importance of vendor rating as a tool for ensuring quality in supply chain management and improving operational performance. It highlights the evolution of procurement strategies beyond just cost to include quality and service delivery, and outlines various methods for assessing vendor performance. Additionally, it emphasizes the need for organizations to adopt a structured approach to vendor evaluation to enhance overall supply chain effectiveness.