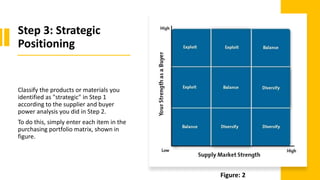

The document outlines the strategic role of purchasing and supplier selection in supply chain management, emphasizing the importance of strategic planning and supplier evaluation for effective procurement. It discusses the Kraljic model for purchasing portfolio management, supplier selection criteria, and the shift towards customer-centric supply chains that prioritize real-time data and customer needs. Additionally, it highlights the evolving challenges and technological advancements shaping supply chain management in the 21st century.