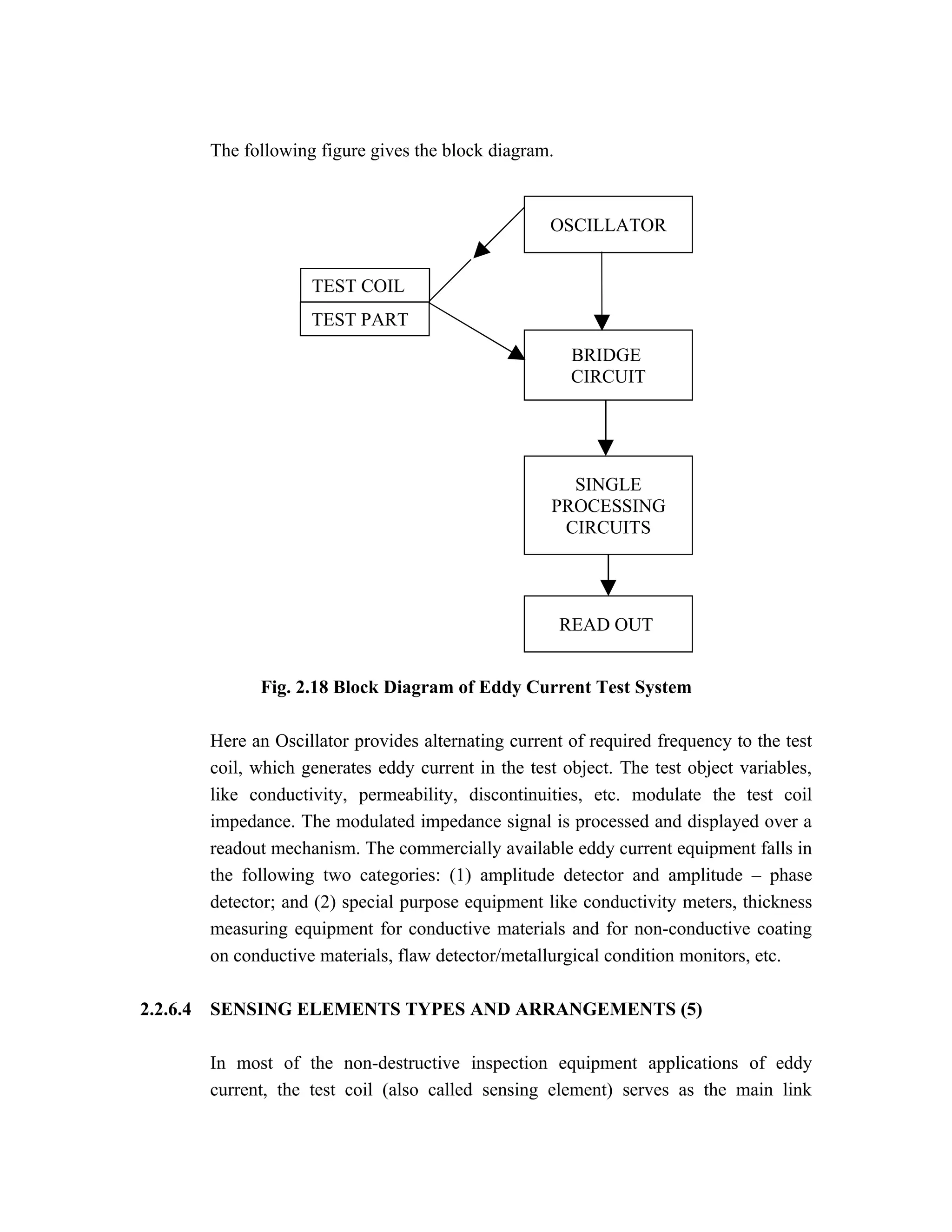

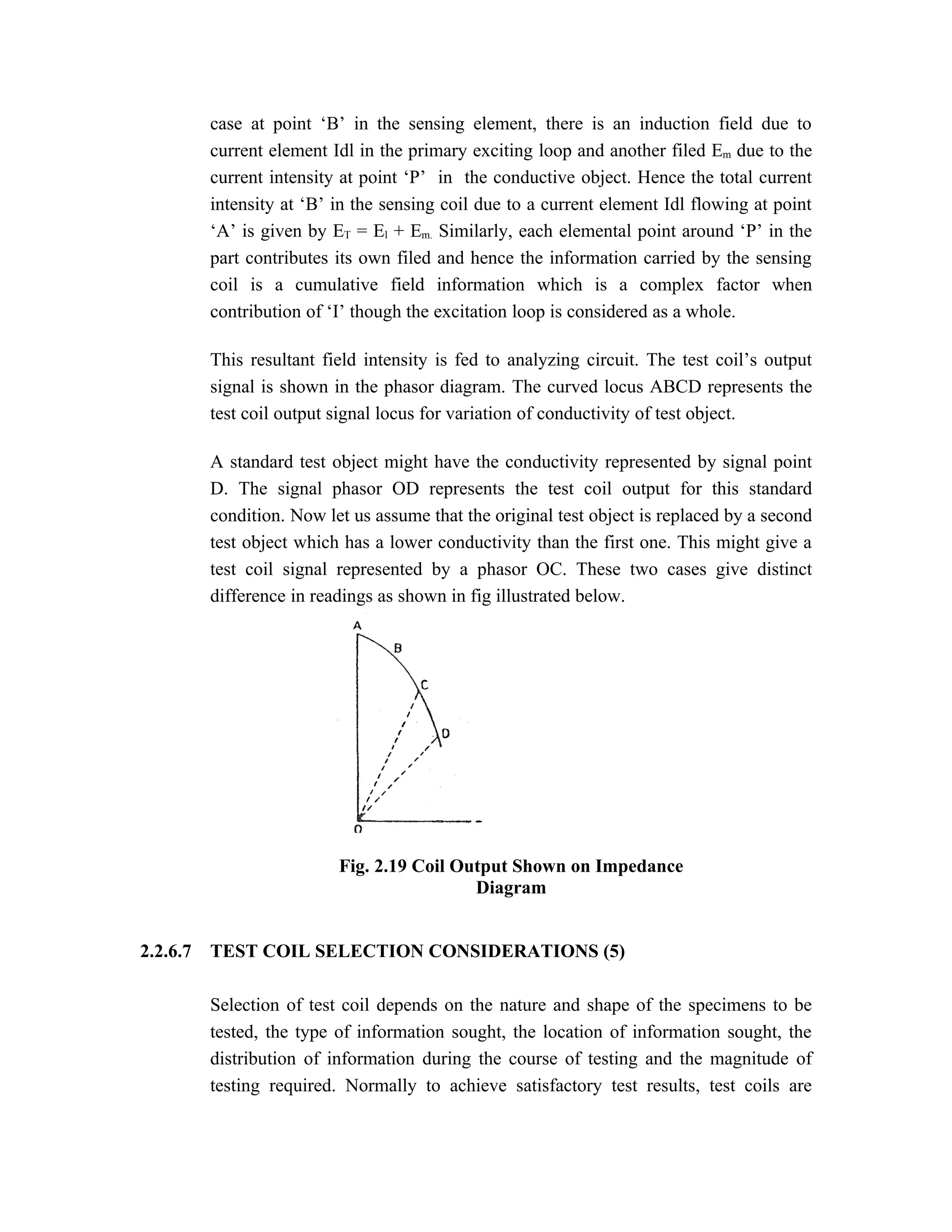

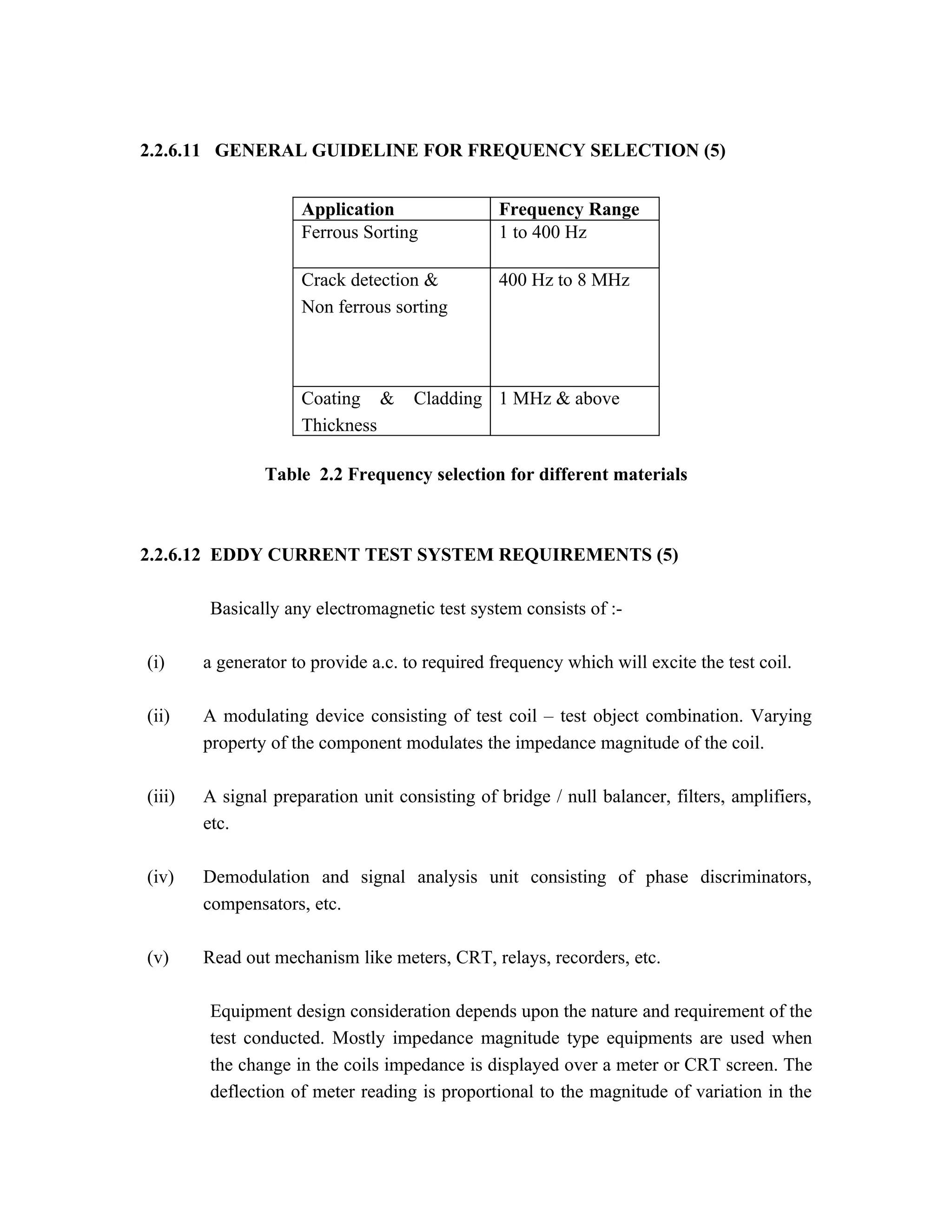

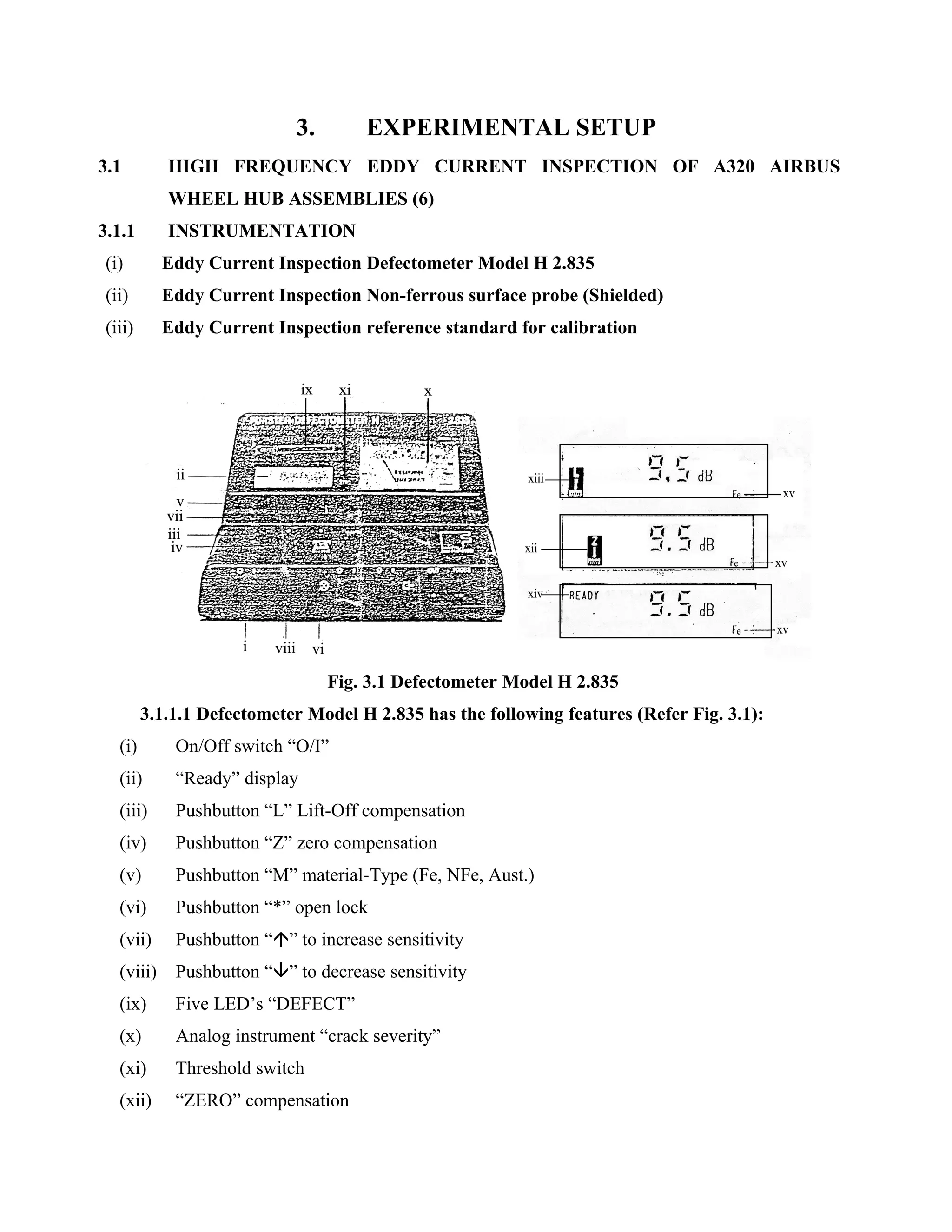

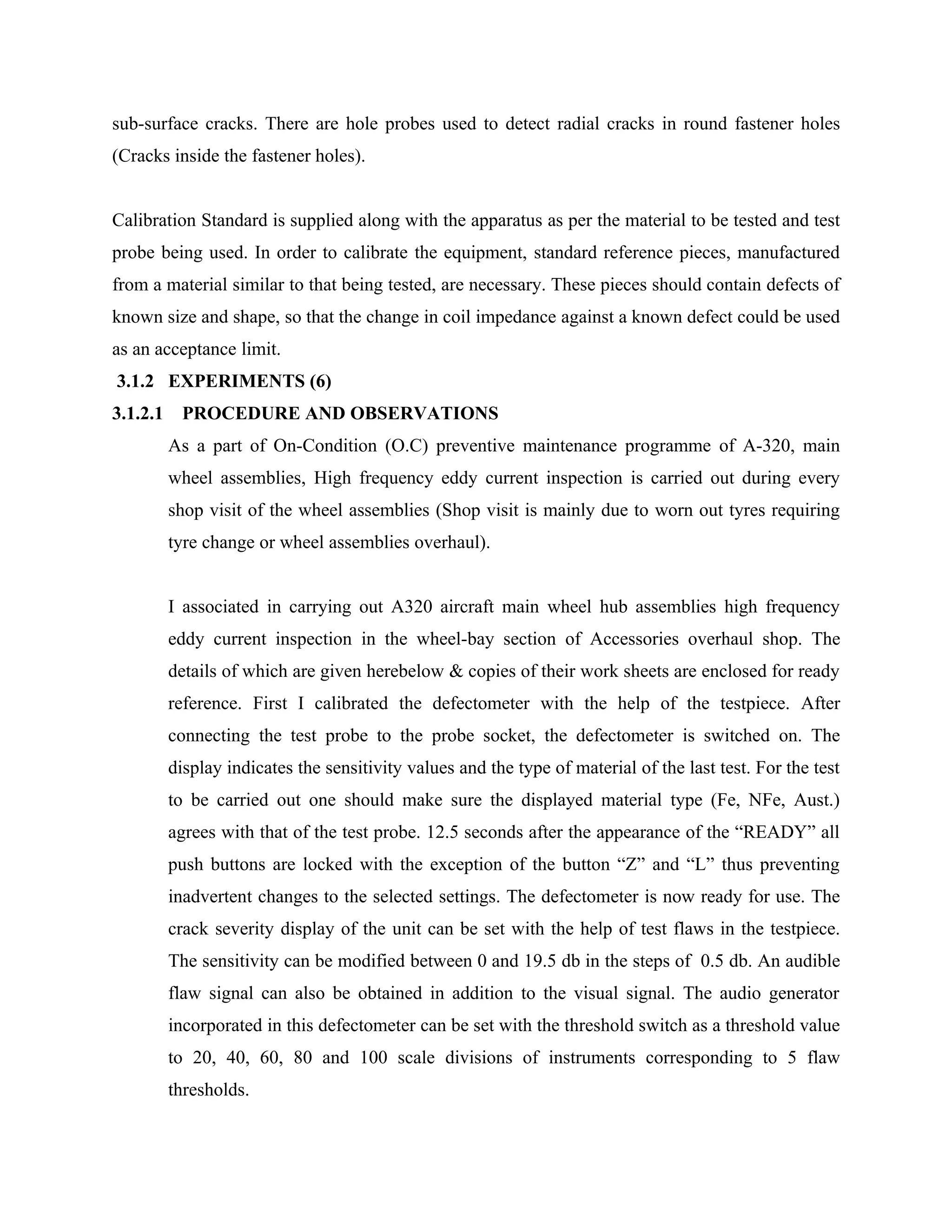

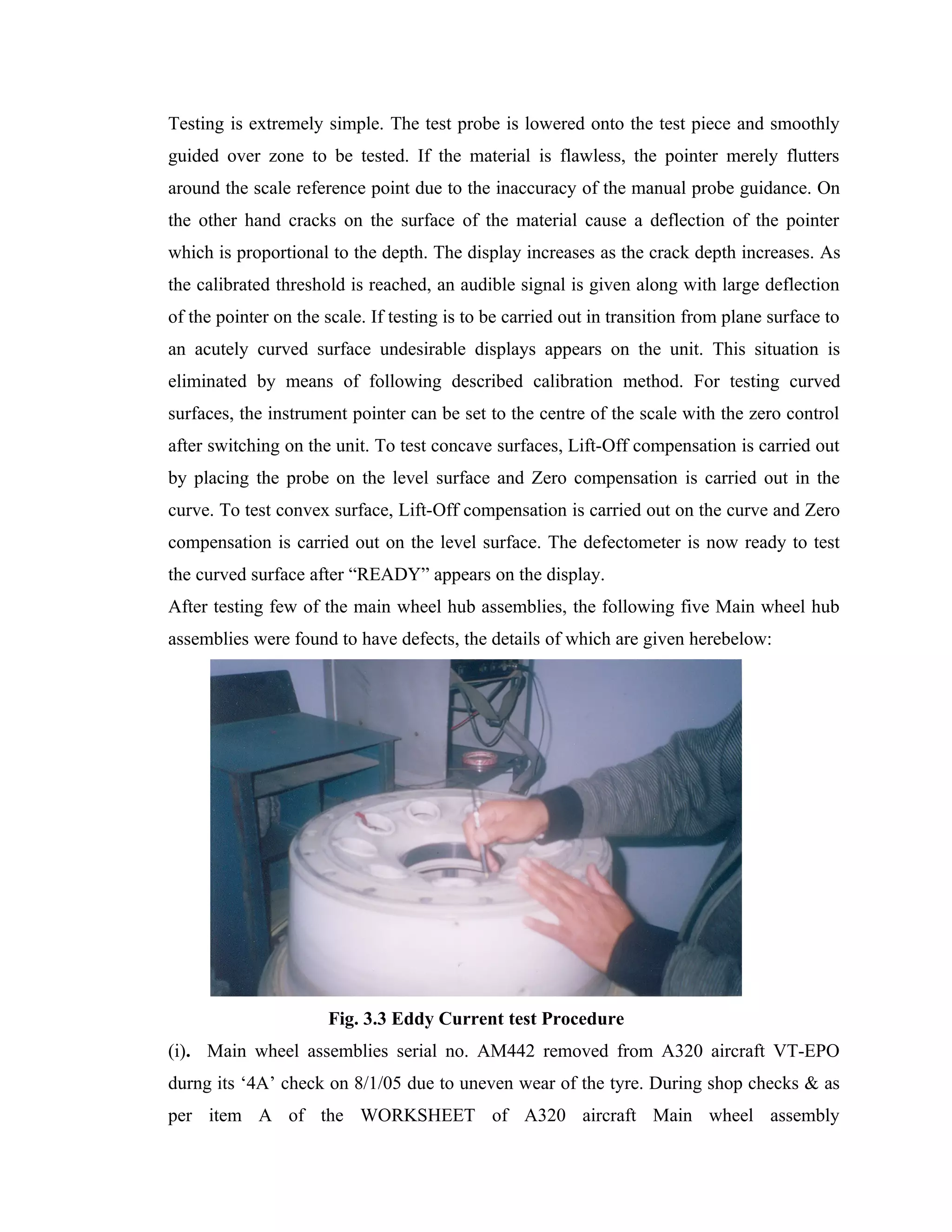

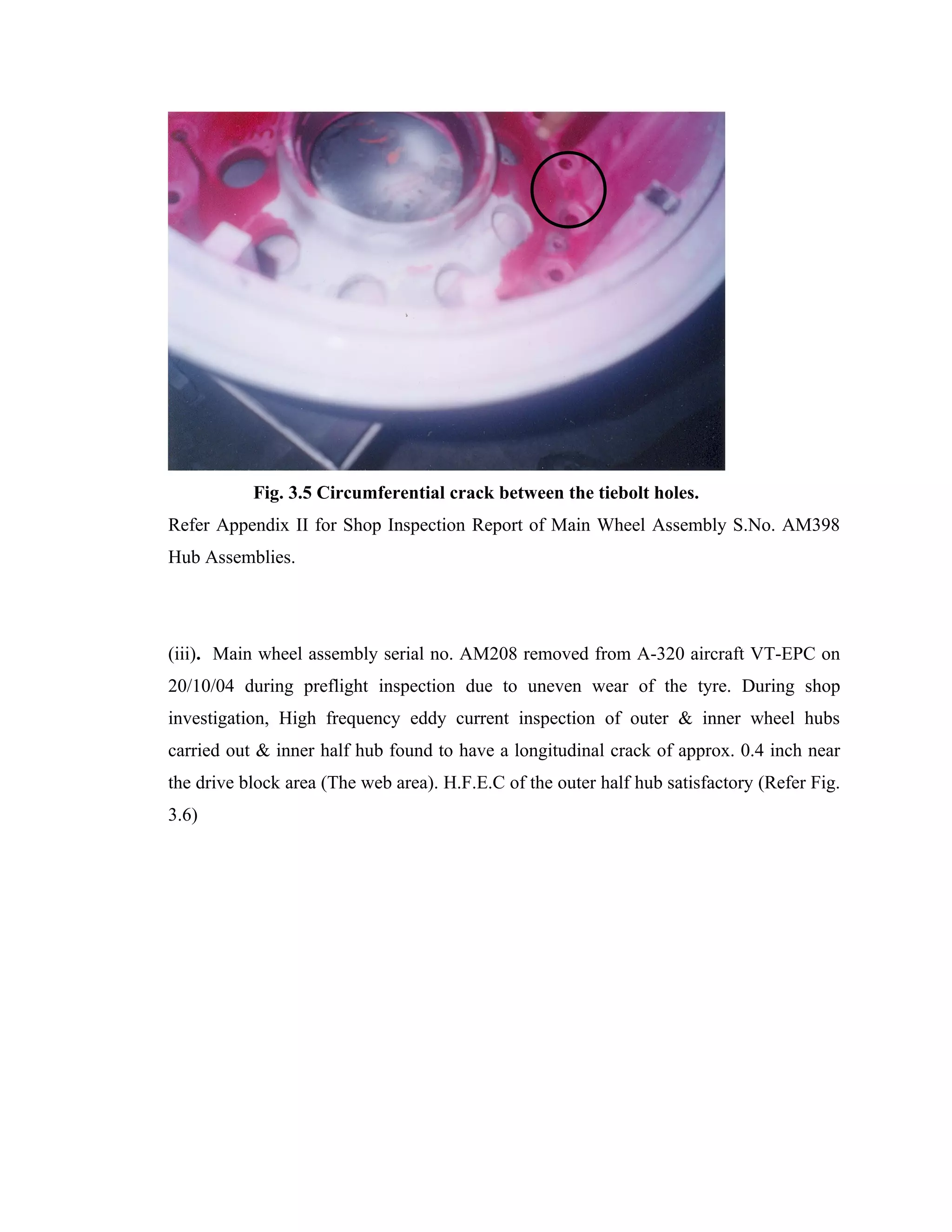

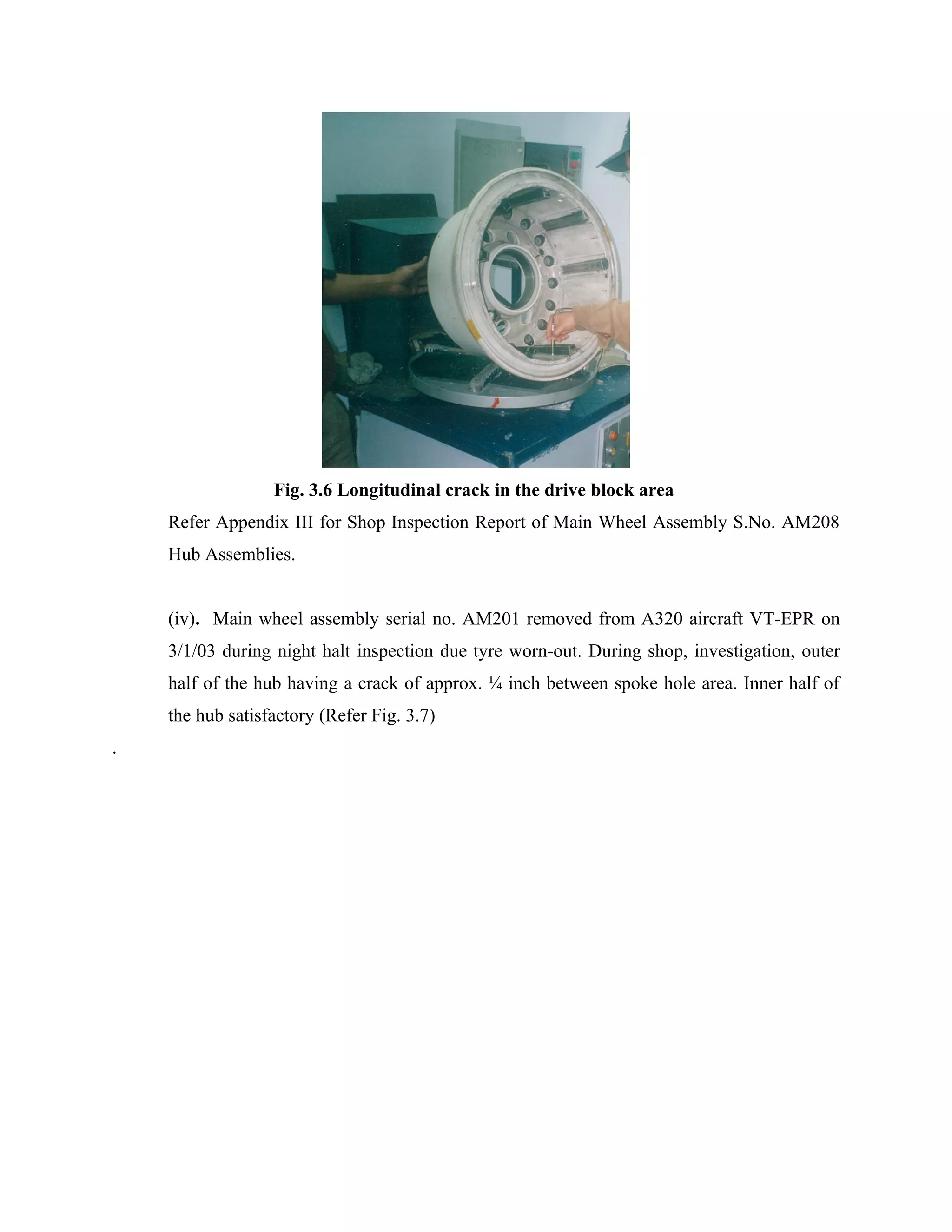

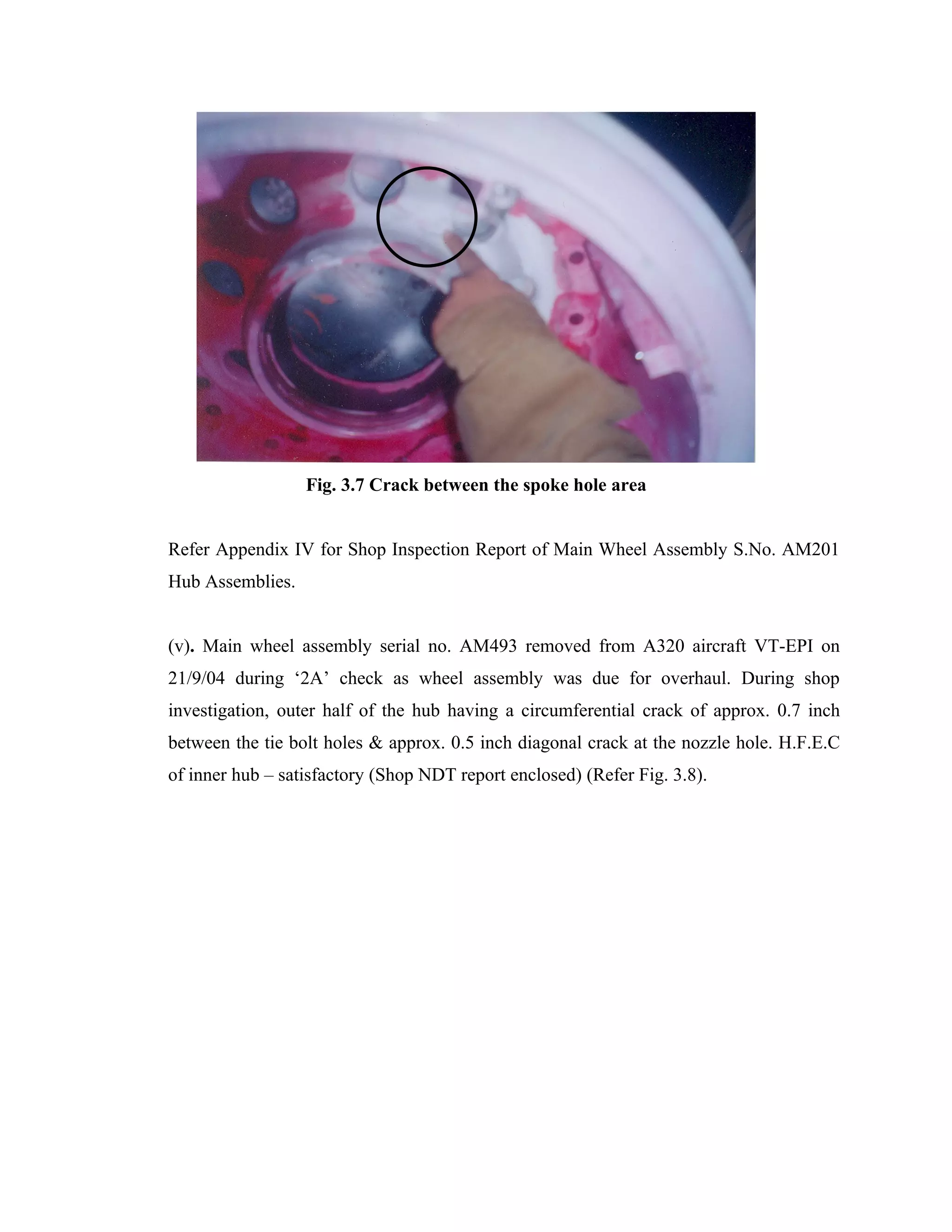

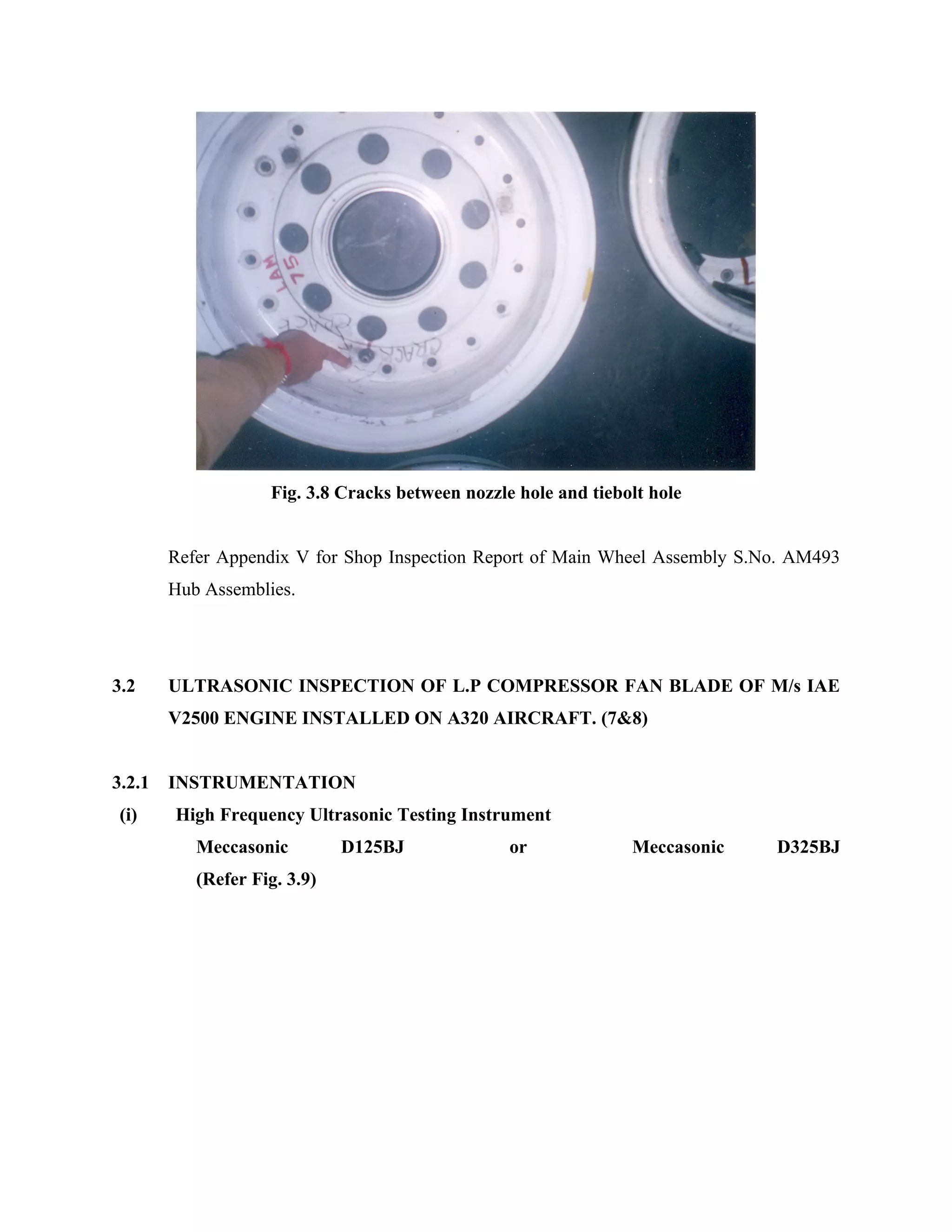

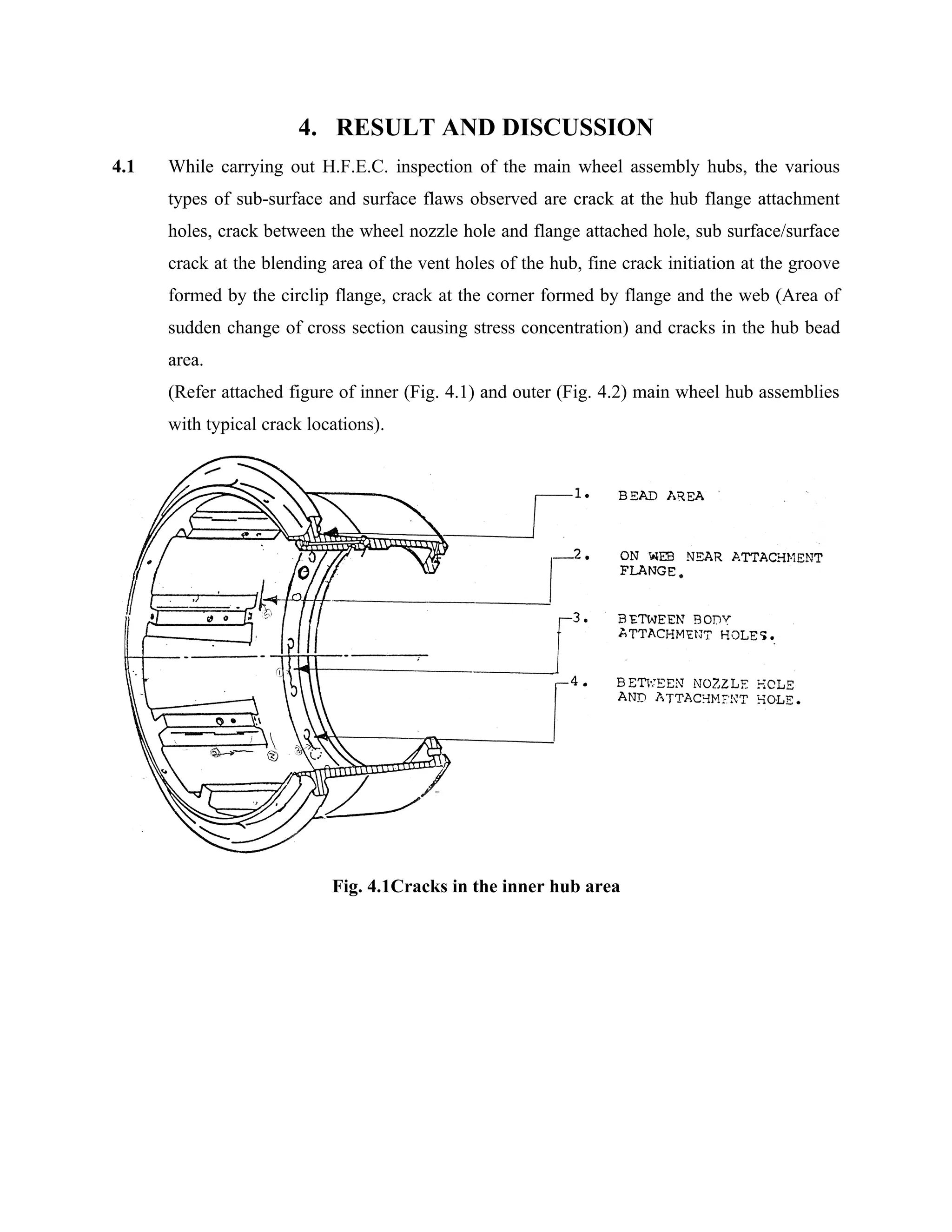

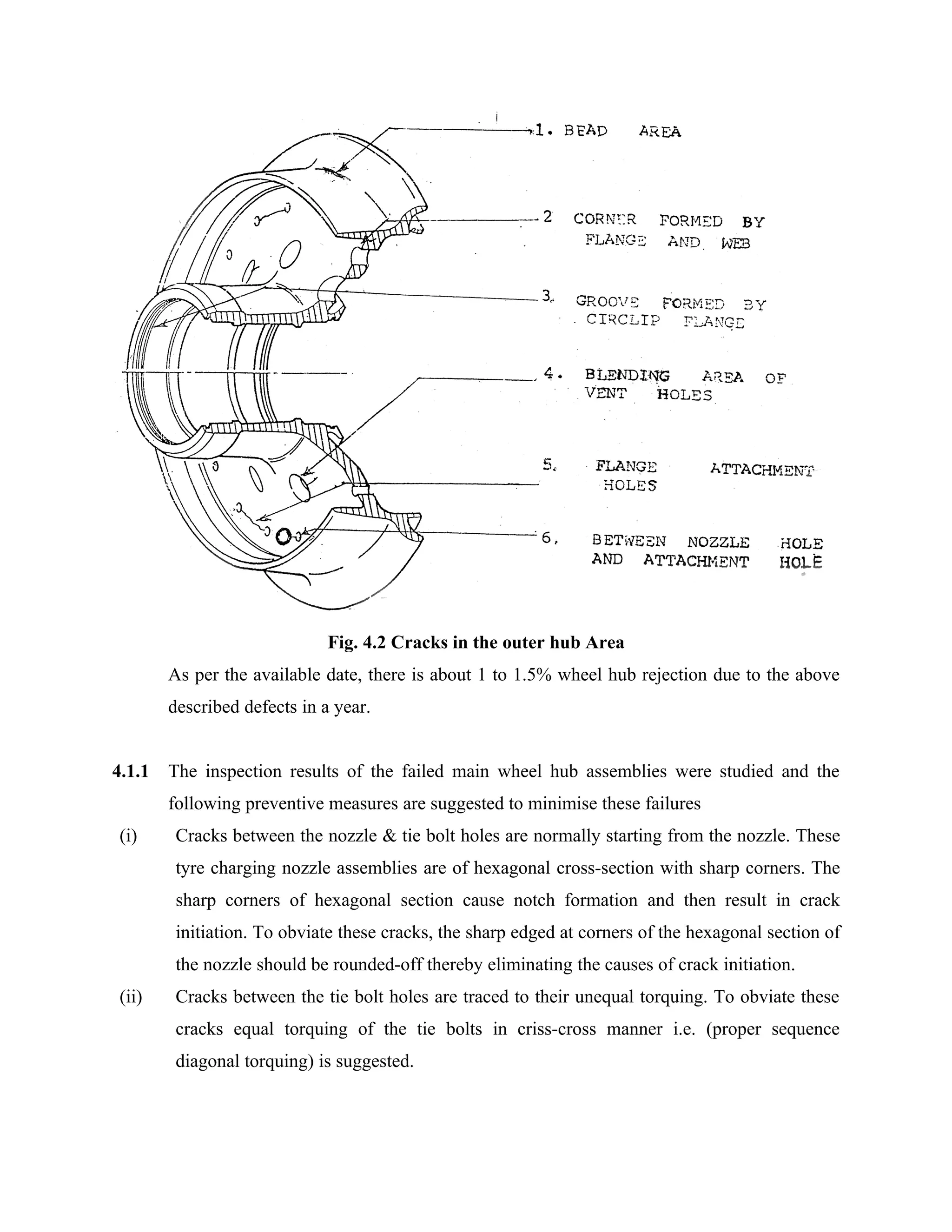

This document provides a summary of Karan Duggal's final year major project on the study of various non-destructive testing techniques. The project involved studying different NDT methods like eddy current testing, ultrasonic testing, visual testing and their applications. Specifically, the project included performing high frequency eddy current inspection of wheel hubs from an Airbus A320 aircraft and ultrasonic inspection of fan blades from an IAE V2500 engine installed on an A320. The results from these inspections were analyzed to identify defects and recommend remedial measures to improve reliability and prevent failures. The document emphasizes the importance of NDT in detecting critical flaws early to avoid safety issues and unscheduled maintenance.