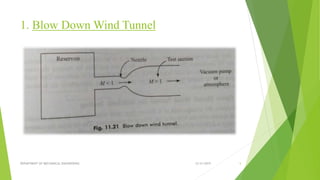

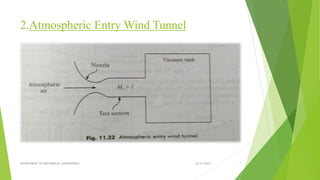

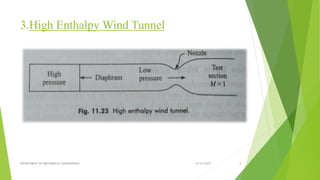

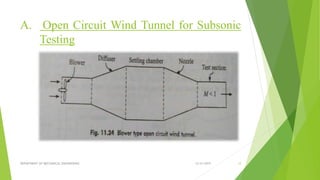

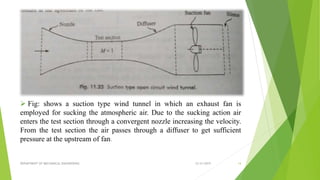

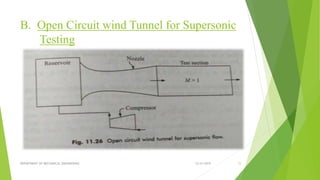

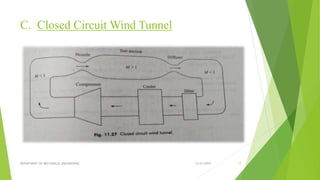

Wind tunnels come in several types depending on their design and airflow characteristics. The document describes blow down, atmospheric entry, high enthalpy, and continuous flow wind tunnels. Continuous flow wind tunnels can be open circuit for subsonic or supersonic testing, or closed circuit. Open circuit tunnels work by drawing in air and exhausting it, while closed circuit wind tunnels recirculate the air through a compressor. The different wind tunnel types are used to simulate various flow conditions for testing aircraft and missile components.