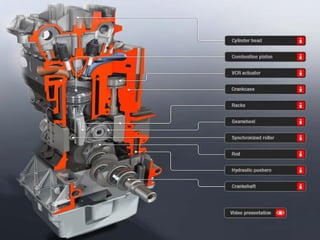

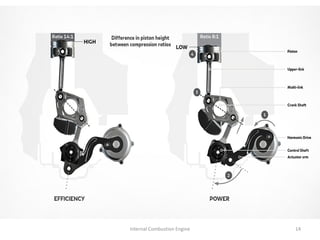

The document provides an overview of variable compression ratio (VCR) engines, detailing their definition, advantages, and historical development. Key features include adjustments made during engine operation, resulting in improved fuel economy and low emissions. Various mechanisms to change the compression ratio are also discussed, along with notable examples of VCR technology by different manufacturers.